These students are putting propeller engines back onto aeroplanes to combat climate change

The majority of commercial aircraft in operation today are equipped with turbofan engines, while a small percentage are powered by propeller engines.

Written by George Fisher-Wilson

Published on Nov. 9, 2017

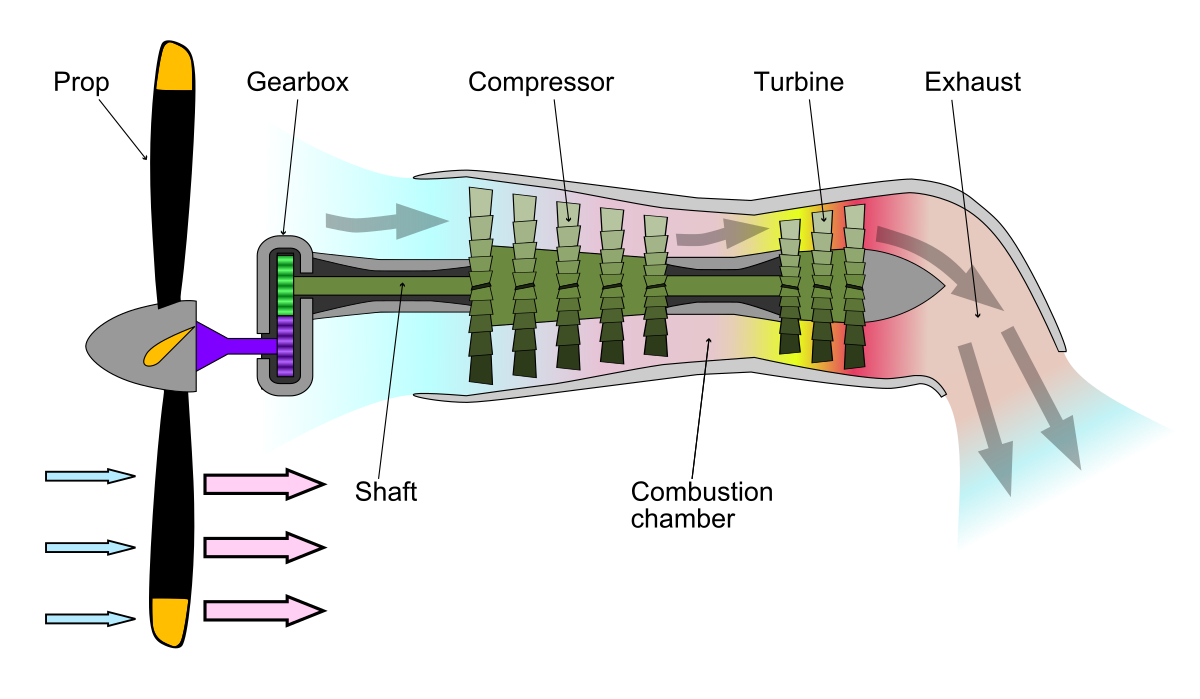

The majority of commercial aircraft in operation today are equipped with turbofan engines, while a few are equipped with propeller engines. The distinction between the two is clear-cut; propeller engines generate thrust through a variance in air pressure between the front and back of their blades, induced by their rotational movement, whereas turbofan engines ignite fuel at extremely high pressure to produce thrust from the exhaust gas (in addition to the rotating turbofan).

The inside of a turboprop engine

The inside of a turboprop engine

Propeller engines offer greater fuel efficiency compared to turbofan engines, making them more environmentally friendly. However, widespread adoption is hindered by challenges such as lower speed, larger size, and increased noise levels, which limit their integration into commercial aircraft.

Tomas Sinnige, a PhD student from the Aerospace Engineering faculty at Delft University of Technology, plays a crucial role in this endeavor. Employing CNC machining techniques, Tomas is fabricating test components for utilization in a wind tunnel. His objective is to devise a configuration that enhances the efficiency of propeller engines on larger commercial aircraft, thereby augmenting thrust.

The aim of this study is to reintroduce propeller-based engines to commercial airplanes, with the goal of decreasing the carbon emissions of the aviation sector and offering insights for upcoming design developments.

Tomas is currently delving into methods to enhance engine efficiency and thrust after previously exploring strategies to minimize noise. The study is centered on analyzing the effects of propeller-airframe interaction and devising a configuration that will not only enable propeller engines to operate on commercial aircraft but also boost the achievable flight speed.

The project commenced a decade ago and was initiated three and a half years ago when Tomas undertook the project for his PhD with a team of five other proficient PhD researchers. Similar research has been conducted previously with simulations carried out by NASA and other smaller research groups, although not on the same magnitude as TU Delft.

The novelty of this study lies in the examination of integrated propeller-wing configurations, which includes comprehensive analysis of all pertinent interaction effects. This has the potential to pave the way for groundbreaking discoveries and provide invaluable insights.

There are various methods to enhance the efficiency of a propeller engine, and one commonly explored approach is the utilization of contra-rotating propellers. However, these propellers pose certain challenges due to their intricate geometries, substantial weight, and heightened noise production compared to conventional propellers.

An example of contra-rotating propellers

An example of contra-rotating propellers

Tomas explains:

“I am currently investigating the concept of utilizing a similar setup of two propellers, but with the addition of fixing the second propeller alongside a fixed row of vanes. This arrangement aims to capture some of the leftover swirl, in the anticipation of enhancing both the propulsion and effectiveness. These fixed vanes are commonly referred to as swirl recovery vanes (SRVs).”

5 of the SRV ‘s created.

5 of the SRV ‘s created.

The SRVs had to possess a high level of durability and resilience in order to endure the intense conditions within a wind tunnel. To evaluate their performance, the configurations were examined using a scaled-down model in the wind tunnel, featuring a propeller with a diameter of 0.24m. Consequently, the blades were relatively diminutive and intricately designed. To ensure the creation of a precise test model, Tomas sought assistance from Protolabs Network’s CNC service. Alternative manufacturing methods, such as 3D printing, were deemed unsuitable due to their inability to achieve the desired combination of intricate design and functional strength.

The width of one of the SRV’s

The width of one of the SRV’s

Tomas had initially employed 3D printing methods like stereolithography (SLA printing) and laser sintering for testing purposes. However, he discovered that the parts produced were excessively flexible and prone to shattering during testing. By turning to CNC services, Tomas acquired aluminum parts that were precise, durable enough to endure the applied forces, and possessed an ideal surface finish for evaluating the aerodynamics of the configuration.

Tomas:

“We searched online for a company that could meet our tight budget and deliver within a short timeframe. The parts had a complex geometry, making it difficult to obtain quotes for the two-week turnaround time we required. Protolabs Network provided us with the parts within budget and on schedule. We were extremely pleased with the quality of the parts as well.”

The SRV’s mounted and ready for testing in the wind tunnel

A total of 15 components were manufactured, consisting of 2 groups of 5 vanes and 5 interval components to divide the vanes for testing at various circumferential positions. The aim of this doctoral research is to further explore the field of Aerospace engineering with the goal of achieving noise reduction and improved efficiency to enhance the feasibility of propellers for future aircraft applications. As air travel is projected to rise and the number of remote destinations continues to grow, this research plays a crucial role in addressing the anticipated increase in emissions.

Upload your 3D files to get an instant CNC quote

Here