Table of Contents

Rapid Sheet Metal Prototyping Services

1 off prototyping & 1000+ production parts

XinYang provides custom sheet metal prototyping services that present a quick and cost-efficient answer for your projects. The services encompass bending, punching, and cutting standard gauge metal for prototypes and low volume production runs. Sheet metal fabrication results in sturdy, final-use metal components with an extensive range of materials and finishes that adhere to your requirements, catering to various industries such as Automotive, Medical device, Aerospace, electronics, energy, and robotics.

Advantages of Sheet Metal Fabrication

1 Material selection

Aluminum + , copper, stainless steel + , steel and zinc

2 Finishing options

Bead blasting, anodizing, plating, powder coating and custom finishes

3 Thickness options

Variety of gauges available

4 Durability

Sheet metal fabrication produces durable parts for prototyping or end use

5 Scalability

Low setup costs mean low prices for large volumes

6 Turnaround

Parts delivered in just 5-10 days

Common Sheet Metal Applications

- Appliances

- Body panels

- Brackets

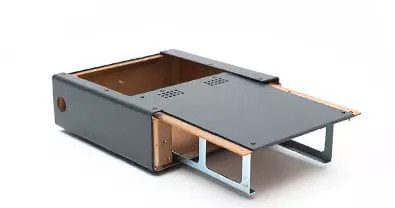

- Chassis

- Doors

- Enclosures

- Fuselages

- Kitchen equipment

- Office equipment

What is

Sheet Metal Fabrication?

Sheet metal fabrication encompasses a series of production techniques employed to transform sheet metal stock into operational components. Typically, the sheet metal ranges from 0.006 to 0.25 inches (0.015 to 0.635 centimeters) in thickness.

Various procedures are categorized under the term ‘sheet metal fabrication’. These procedures encompass cutting, bending, and punching, and can be applied collectively or separately.

Sheet metal fabrication can be utilized to produce either functional prototypes or final products, however, final sheet metal parts typically necessitate a finishing procedure prior to being market-ready.

Sheet Metal FAQ

Do I need laser cutting, water jet cutting or plasma cutting?

The cutting machine utilized is determined by the selected material, sheet thickness, lead time requirements, and tolerance specifications.

We are aware of the projects that require specific equipment, therefore there is no need for you to mention a particular cutting machine.

Does it cost more to use multiple sheet metal forming processes?

Typically, a component that undergoes cutting, bending, and punching processes will be more expensive compared to a component that is solely cut using a laser cutter.

Nevertheless, the majority of sheet metal components require a blend of forming techniques, which will not result in a significant price hike.

Is there a minimum order quantity?

No, it is possible to place an order for either a single prototype or a quantity exceeding 1,000 units.

Start Your Project With A Free Quote