.

.

.

.

.

.

What is CNC Milling: Definition, Work Process & Technologies

CNC milling stands as a remarkable technological breakthrough of this era.

While many individuals may be more accustomed to 3D printing for creating accurate physical objects, CNC milling has a longer history and continues to be commonly utilized in the present day.

The technology continues to rapidly grow and evolve as an increasing number of companies in the electronics industry and manufacturing sector are recognizing its effectiveness. With its wide range of applications, it has become prevalent in various industries.

However, despite the fact that individuals working in the industry are well-acquainted with the process and applications of CNC milling, those who are not part of the industry may have limited knowledge about its uses and functionality.

In this article, we will delve into the topic of CNC milling, exploring its distinctions from 3D printing, identifying the potential beneficiaries of this technology, and addressing any key inquiries you may have.

What is CNC Milling?

In order to comprehend the CNC Milling process, it is essential to deconstruct it into its two fundamental components – ‘CNC’ and ‘Milling’. Milling involves a machining operation where a workpiece is rotated along rotational axes, while cutting tools are utilized to remove pieces of the workpiece.

The purpose of this process is to mold the workpiece according to the desired specifications. It is crucial to highlight that this technique varies from alternative shaping approaches such as 3D printing.

This occurs because milling operates by subtracting material from the workpiece, whereas other alternatives involve adding material to the workpiece.

Who Invented CNC Milling?

The origin of milling can be traced back to the 18th century, but it was not until the early 1950s that the initial CNC milling machines were created.

Richard Kegg is credited with the invention of CNC milling machines. In collaboration with MIT in 1952, he developed this machine and named it the Cincinnati Milacron Hydrotel.

How Does CNC Milling Work?

CNC milling is essentially a fundamental procedure in which an initial workpiece is continuously subjected to material removal at various points using a cutting tool. In order to access these distinct points, the workpiece undergoes continuous rotation.

The CNC milling process actually involves several steps.

What are the different stages of a typical CNC Milling process?

Creating CAD Model

To begin with, it is essential to create a blueprint of your desired part shape using a CAD model. CAD, which stands for Computer Aided Design, is a software that assists in the creation of 2-D or 3-D models for various purposes.

Creating CAD Model

To begin with, it is essential to create a blueprint of your desired part shape using a CAD model. CAD, which stands for Computer Aided Design, is a software that assists in the creation of 2-D or 3-D models for various purposes.

Setup of CNC Milling Machines

Prior to commencing the program, it is crucial to adequately configure both the machine and the workpiece. The specific procedures for setting up the CNC machine may differ depending on the manufacturer and model being utilized.

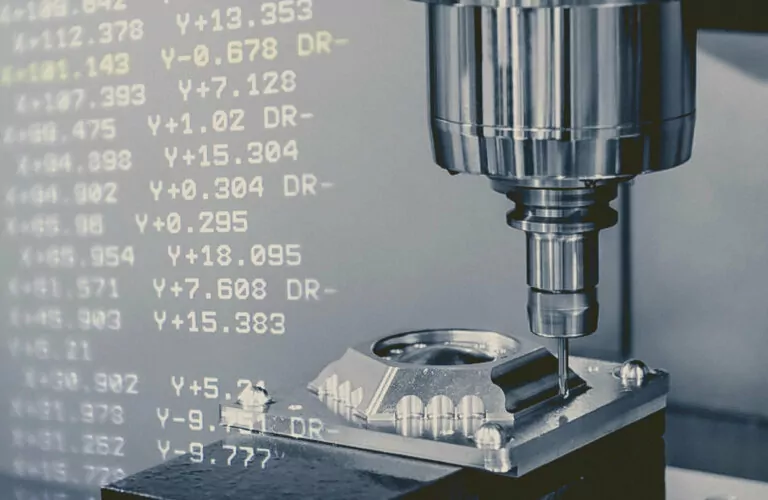

Converting CAD to CNC

The CNC milling machine lacks the ability to directly interpret a CAD model. However, converting the CAD model into a CNC program is a relatively straightforward process. Most CAD software packages offer these functionalities as standard.

What are the Different CNC Milling Methods?

The CNC milling process has expanded significantly, evolving from a single process into a complex field. Today, there is a wide range of CNC milling operations to choose from. Some of the various methods include:

Plain Milling:

Version 1: Plain milling stands as the most widely used milling technique. Its primary objective is to produce flat surfaces that run parallel to the rotational axes of the cutting tool.

Angular Milling:

Angular milling is a milling process where material is removed from a flat surface using a cutter that is positioned at an angle other than 90 degrees. To gain a clearer understanding, envision an inclined cutter eliminating material from the workpiece.

Face Milling:

The milling process known as face milling involves milling the workpiece at a perpendicular angle to the rotational axes of the cutter. This technique is commonly used for machining the surfaces of bars and plates.

Form Milling:

The form milling process is utilized for machining the workpiece in order to produce non-uniform surfaces like curves. In this process, the cutter’s shape matches the desired shape of the contours.

Other CNC Milling operations

In addition to these conventional CNC milling techniques, there exist several alternative approaches for fabricating customized components. These approaches encompass:

Gang Milling:

Gang milling involves mounting two or more cutting tools on a single machine arbor. Each cutter operates independently on the workpiece, leading to a higher production rate. The cutters may differ in terms of their shape and size.

Straddle Milling:

Straddle milling is a unique type of gang milling machine where two or more cutting tools are positioned in parallel to each other. These tools effectively operate on both the face and sides of the workpiece simultaneously.

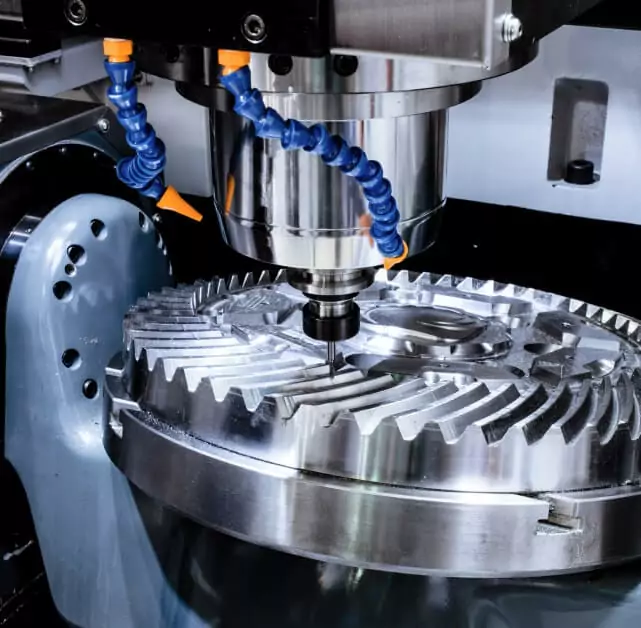

Gear Milling:

Gear milling, also referred to as gear cutting, is a specialized milling process used specifically for producing gears. This method involves the use of curved cutters to shape the gear teeth spacing by removing excess material.

Profile Milling:

Profile milling is utilized to finalize the shaping process, which involves working on vertical or slanted surfaces. This CNC milling technique is also employed to complete the convex and concave surfaces of the workpiece.

Equipment and Components of CNC Milling Process

Throughout the entire CNC milling process, you will encounter various components.

Support Software

As previously stated, the creation of a CNC model necessitates the utilization of both Computer Aided Design (CAD) software and Computer Aided Manufacturing (CAM) software. CAD is responsible for the design aspect, while CAM ensures that the CNC machine comprehends the design.

CNC Milling Machine Components

Obviously, CNC milling cannot be completed without a CNC milling machine. There are many different types of milling machines out there. The components of the machine can vary based on the model you use.

Typically, all CNC milling machines consist of the following components:

- Worktable: The workpiece needing CNC milling is secured to the worktable using a clamping device. Typically, the worktable supports the workpiece during the machining process.

- Saddle: The worktable is equipped with a saddle underneath to provide support. Additionally, the saddle enables the worktable to move parallel to the spindle axis.

- Spindle: The spindle is in charge of holding the cutting tool, also referred to as the cutting tool, and is responsible for controlling the movement of the cutting tool.

- Arbor: Arbors are the shafts that pass through the spindle. In gang milling and saddle milling, several cutting tools can be attached to a single arbor. Arbors vary in shapes and sizes, with their application determined by the specific needs and the type of milling machine being used.

- Ram: Ram is typically found in vertical milling machines and angular milling machines, providing support to the spindle. It can be adjusted to various positions to meet different cutting needs.

- Machine Tools: A machine tool or cutting tool is utilized to eliminate material from the workpiece. Various types of cutting tools are accessible, and we will discuss them briefly.

- Interface: The digital console found on the CNC milling machine is known as the Machine Interface. It is utilized by the operator to input and run programs, as well as carry out fundamental CNC milling tasks.

- Knee: The knee is located beneath the saddle to offer support. It is possible to vertically adjust the knee’s position. Raising or lowering the knee allows for the flexibility to adjust the workpiece height according to various milling needs.

- Column: The column serves as the backbone of the CNC milling machine, offering structural support to the entire assembly. It may contain internal compartments for storing cooling oil and other components.

What are the Various Kinds of Cutting Instruments for CNC Milling Equipment?

CNC milling offers a wide array of uses, resulting in the presence of a variety of cutting tools designed for particular purposes. Some instances of such tools are:

End Mills

Face Mills

Slab Milling

Fly Cutter

Ball Cutter

Multi-Point Cutting Tools

Hollow Mill Cutter

Involute Gear Cutter

Threads Cutting Tool

Slide and Face Cutters

Hobbling Cutter Tool

Dovetails Cutter Tools

Roughing End Mills

What are the Different Types of CNC Milling Machines?

Here is a short overview of the different types of CNC milling operations in use.

Milling in a horizontal direction

The spindle in horizontal machines is positioned parallel to the workpiece surface, enabling the creation of flat surfaces, planes, inclined planes, and grooves on the

workpiece.

Milling in a vertical direction

Vertical milling operations can be likened to drilling operations, given that the spindle is oriented perpendicular to the stationary workpiece or the flat moving surface of the workpiece.

Milling in Multiple Axes

In multi-axis milling, the cutting tool has the capability to move in four or more directions.

When there are 5 directions involved, the machine is referred to as a 5-axis machine. As the number of axes increases, the machine is capable of producing more complex parts.

Milling with Column and Knee.

Column and knee milling machines, also known as variable speed milling machines, feature a highly precise vertical movement of the column and knee assembly, enabling accurate vertical milling operations.

Ram Milling Machine

The cutting tool in a ram milling machine can be horizontally moved either forward or backward by utilizing a movable ram that is connected to the spindle.

Fixed Bed Manufacturing Milling Machine

These machines do not involve any movement of the column, knee, or saddle. The worktable, where the stationary workpiece is placed, is directly mounted on the bed of the machine. Thanks to their uncomplicated design, these machines are typically more affordable compared to their counterparts.

Planer Milling Operations

Planer milling is a machining process where the cutting action takes place in a singular plane through the linear movement of both the workpiece and the cutting tool. This type of milling is commonly employed to produce smooth and even flat surfaces.

To determine the milling machine that suits your needs, we recommend consulting our comprehensive guide on the subject.

What Are The Applications and Uses of a CNC Milling Machine?

To gain a precise understanding of the applications of CNC milling, we can categorize our discussion into two sections: the materials it accommodates and the industries that directly or indirectly utilize this process.

You are already acquainted with the concept of CNC milling, which is utilized to shape and mold parts according to specific requirements. Below are the materials suitable for undergoing the CNC milling process:

Materials Compatible With CNC Milling

Metals are frequently utilized in the milling process as they are a commonly found material. Due to their high melting point, metals cannot be used in processes such as 3D printing, making CNC milling the optimal method for shaping them.

CNC milling is compatible with both Plastics and Elastomers, thanks to their unique physical and chemical properties. However, it is important to note that subjecting plastics to high-temperature methods during CNC milling can alter their chemical composition.

Furthermore, toxic fumes are emitted when heated. Hence, materials like those used in CNC milling, which do not require heat, are perfect for such applications.

Ceramics and composites frequently exhibit temperature resistance properties, rendering them unsuitable for 3D printing and molding procedures. CNC milling is the most effective method for working with these materials, as it can operate without causing any damage to them.

A lesser-known fact is that glass can be shaped using the CNC milling process, which is ideal for this brittle material that can easily break with other shaping methods. By utilizing CNC milling with a suitable cutting tool, one can effectively shape glass with precision.

Refer to our guide on CNC milling materials for detailed information on specific materials and their suitable applications.

Industries That Use CNC Milling Machines

The CNC milling process is utilized by a vast array of industries, and the sheer number of them will undoubtedly leave you astonished.

Certainly, the astonishment will dissipate once you delve into the benefits of CNC milling compared to other options in the upcoming section.

CNC technology is widely utilized for rapid prototyping, offering designers and engineers a quick and dependable method to visualize the appearance of a product or part at different points during the development process.

There are several sectors that employ CNC milling technology:

Automotive

The automotive sector relies heavily on specialized manufacturing services to produce components used in vehicles. CNC milling machines are utilized for both manufacturing and repair operations.

Aerospace

Due to the exceptional precision of CNC milling services, it is evident why they are extensively utilized in the aerospace sector. This technology is essential in manufacturing various parts that are vital for maintaining the safety and efficiency of aircraft.

The aerospace sector extensively deals with a wide range of specialized materials known for their exceptional hardness and ability to withstand extreme temperatures. To shape these materials, CNC milling machines play a crucial role, serving as a vital tool in the industry.

CNC technology is utilized to manufacture various components such as engine parts, landing gear components, and fuel panels.

Metal Fabrication

A CNC milling machine serves as the foundation of the metal fabrication industry. It boasts speed, automation, and efficiency. Moreover, it is capable of working with a wide variety of metals. As a result, milling machines are a common sight in every metal fabrication workshop.

Agriculture

A plethora of large-sized custom tools and components are essential for agricultural equipment. These indispensable elements are meticulously crafted through the employment of custom manufacturing services provided by a CNC milling machine.

Electronics

The electronics industry greatly benefits from the exceptional adaptability and accuracy of the CNC milling machine. This advanced technology is perfectly suited for shaping both the conductors and metals necessary for transmission, as well as the polymer boards that provide a housing for these conductors.

Medical

Specialized components are essential in the medical field, serving not only for diagnostic purposes but also for applications like prosthetics. These components are manufactured through CNC milling, utilizing suitable designs.

CNC milling enables the production of various components and tools using a wide range of titanium and stainless steel grades. These materials are commonly employed in the fabrication of scalpels, medical devices, and implants.

Defense

CNC milling is extensively employed in the production of military components. Interestingly, the milling process was initially utilized for crafting weapons. Furthermore, even prototypes of defense parts are fabricated using a CNC milling machine.

In addition to these sectors, CNC milling is also utilized in industries like mining, oil and gas, automation, energy, and more.

Main Advantages of CNC Milling

CNC milling technology is widely recognized as an exceptionally dependable method for manufacturing parts from diverse materials due to an abundance of compelling factors.

- High Production Rate – CNC milling operates through automation, allowing the cutting tool to move at unrestricted speeds due to the absence of human limitations. Consequently, this results in an unparalleled production rate that surpasses other manufacturing methods.

- Unmatched Precision – CNC milling is renowned for its unparalleled accuracy and precision, making it the top choice for industries such as aerospace and medicine where flawless execution is crucial. By utilizing digital templates and autonomous machining, CNC milling ensures that human error is completely eradicated from the manufacturing process, resulting in near-perfect accuracy that is unmatched in today’s world.

- Longevity – CNC milling machines have the capability to operate almost autonomously, minimizing the need for human intervention. This allows them to operate continuously for extended periods, ensuring consistent production of parts with utmost precision. The only instances where CNC machines necessitate halting are for routine maintenance or in the event of an accident.

- Fewer Personnel – CNC milling is founded on an automated process that reduces the need for constant monitoring and operation by a large workforce. This leads to improved efficiency and lower production expenses. Only a small number of highly skilled experts are necessary to supervise the entire operation, resulting in enhanced cost-effectiveness for the final customer.

- Advanced Possibilities – Due to the utilization of sophisticated automation software and design software, CNC milling machines have the capability to surpass the expertise of highly skilled technicians who operate manual machines, despite the similarity in the manufacturing process. This implies not only enhanced consistency and the eradication of human errors, but also the capacity to fabricate intricate designs encompassing diverse sizes, shapes, and even textures.

- Consistency – Due to the largely automated nature of CNC milling, it ensures a high level of consistency, regardless of any changes in personnel handling the tools. After generating a master file of the design, it becomes possible to replicate an infinite number of copies, all maintaining the same quality and precision. Each component will perfectly match the previous one, a level of accuracy that is challenging to achieve even for highly skilled manual operators.

- Scalable – CNC milling offers a highly adaptable solution that can be implemented by industries of all sizes. Whether you are utilizing it for your workshop, the process can expand in tandem with the growth of your workshop. Moreover, a CNC milling machine can be utilized for components of varying shapes and sizes.