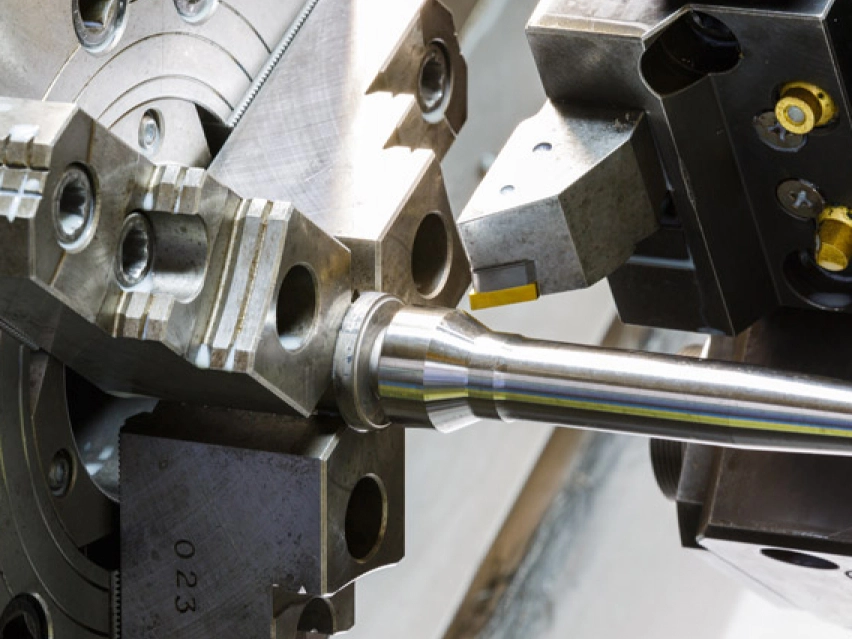

CNC turning service

Our extensive network of advanced CNC turning experts enables us to source top-quality components in over 50 diverse metals and plastics. With the capability to achieve tight tolerances as precise as ±.0008″, we ensure high-performing parts for your specific requirements.

What is CNC turning?

CNC turning is a manufacturing process that involves securing a blank onto a rotating chuck and eliminating material using fixed cutting tools. This technique is particularly suitable for creating parts that possess symmetry along their central axis. Turned parts are generally manufactured more efficiently (and at a reduced expense) compared to milled parts.

Maximum part size for CNC turning

| Restrictions on the size of parts | Metric measurements | Imperial measurements |

|---|---|---|

| Largest diameter of a component | 431 mm | 17 in |

| Maximum length of a part | 990 mm | 39 in |

| The largest swing over the carriage | 350 mm | 13.7 in |

| Spindle through-hole maximum capacity | 40 mm | 1.5 in |

| Version 1: The motor power is 640W with a maximum speed of 1700RPM |

Available materials for CNC turning

We are the preferred choice for top-tier companies in various industries such as aerospace, automotive, defense, machinery, medical technology, robotics, electronics, oil & gas, and industrial automation. These companies rely on us for the creation of rapid prototypes and production parts that demand exceptional levels of precision and intricacy.

CNC turning surface finishes

Improve the performance of components by choosing surface finishes that enhance roughness, hardness, chemical resistance, and cosmetic attributes of the finished part.

CNC turning tolerances

Our CNC machining operations adhere to ISO 2768 standards

| Limits for the nominal dimension | Plastics conforming to ISO 2768-m | Metallic materials (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm | |

CNC turning design guidelines

Please review the suggested and technically viable parameters for the predominant characteristics of components manufactured using precision CNC turning.

| Attribute | Optimal dimensions | Achievable dimensions |

|---|---|---|

| Min.feature size | Ø 2.5 mm | Ø 0.50 mm |

| Internal.boundaries | R 8 mm | R 0.25 mm |

| Minimum.wall.thickness | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Cavities | Diameter: standard drill bit sizes Depth: 4 x diameter | Diameter: Ø 0.5 Depth: 10 x diameter |

| Strands | Size: M6 or larger Length: 3 x diameter | Size: M2 |

Our CNC turning operations adhere to stringent quality standards

Our custom parts are produced in compliance with rigorous manufacturing regulations, guaranteeing that all components and procedures meet The Protolabs Network Standard.

- There are various surface finishes accessible to enhance the aesthetic appearance of your components following the machining process.

- Our manufacturing partners conduct on-site inspections of each custom part in accordance with our guidelines.

- Inspection reports and various forms of quality documentation can be provided upon request to ensure the utmost quality and adherence to regulations.

Additional materials available for CNC lathe operations

Discover more about the functioning of CNC turning and enhance your understanding of designing superior components for this particular machining technique