Inhoudsopgave

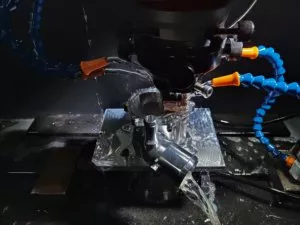

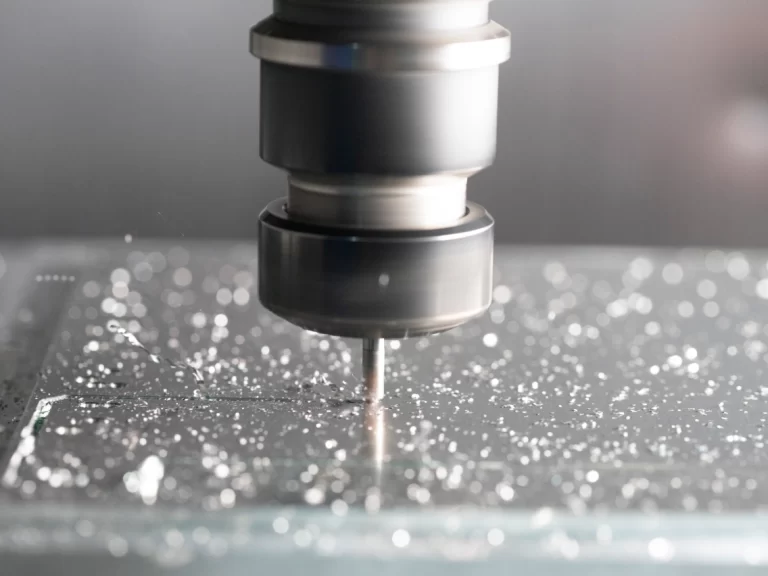

Precision CNC Machining for Metals & Plastics

Fast Delivery of High-Precision Solutions

When seeking precision machining services, it is crucial not to sacrifice quality in order to produce parts that align with your quality standards. XinYang provides a diverse selection of precision CNC machining services, a skilled team of professionals, and a wealth of knowledge on the most effective strategies for various projects utilizing 3-, 4-, and 5-axis CNC machines. Our services include CNC milling & CNC turning, EDM, wire EDM, and surface grinding, covering all technical requirements for developing prototypes and parts, enabling you to concentrate on launching your product successfully.

Our Proficiency in Precision Machining.

Initially, we possess the knowledge on producing precision parts. Regardless of the tight-tolerance parts we encounter, our engineers can select the most appropriate method for manufacturing them with a focus on minimizing costs.

With the aid of top-notch machinery, equipment, clamps, fixtures, and an on-machine, real-time inspection system, we are capable of achieving more precise tolerances compared to other machining workshops.

Furthermore, our Quality Control department is staffed with highly skilled professionals who possess extensive expertise. These individuals are well-versed in operating various inspection tools such as laser projectors, CMMs, and 3D scanners. As a result, they guarantee that all our produced components adhere to the utmost quality standards.

The Benefits of Precision Machining We Offer

There exists a vast array of precision machining providers. What sets us apart from the rest? Allow me to present the three primary justifications:

1. Experience

Our engineers possess extensive expertise gained from numerous past projects, enabling them to effortlessly manage intricate and accurate components across various industries.

2. Sophisticated Machinery

XinYang possesses a wide range of in-house equipment for manufacturing and testing purposes. Our advanced in-house equipment, such as Precision CNC milling, CNC turning, EDM, Hexagon CMM, and Olympus XRF analyzer, will be utilized to manufacture and inspect your parts.

3. Fast Turnaround

On average we return quotes within 24 hours, parts ship within 7 days or less, and we have a 99% on-time delivery and quality rate.

Advantages of Precision Machining

Precision machining is a crucial manufacturing procedure that empowers companies to fabricate intricate components with the utmost precision and narrowest allowable deviations. Below are merely a few of its primary benefits when compared to alternative methods:

1. High Precision:

Precision molding, as its name suggests, provides unmatched precision, ensuring consistent excellence in the production of each and every part.

2. Minimal Errors:

Because precision machining uses CNC technology, it is largely automated and reduces the probability of error to a minimum.

3. Efficiency:

Due to the utilization of CNC technology, precision machining is predominantly automated, thereby minimizing the likelihood of errors to an absolute minimum.

4. Less Waste:

Precision machining minimizes waste, resulting in material savings and the ability to uphold environmentally-conscious manufacturing methods.

5. Cost-Effective:

The advanced technology involved in the process results in reduced waste, decreased labor requirements, and a minimal risk of errors, making it an extremely cost-efficient method of manufacturing.

Precision Machining FAQ

When to choose precision machining?

It is common for engineers to recommend extremely tight tolerances when designing parts, often exceeding the necessary requirements. This practice is not considered optimal. Opting for a tolerance of +/-0.01mm instead of the required +/-0.05mm can significantly raise manufacturing costs. Nevertheless, in cases where precision machining is essential for tolerances as tight as 0.01mm, it provides unparalleled accuracy and consistency.

What materials can be used with precision machining?

There is a vast selection of materials suitable for precision machining, including aluminum, brass, copper, steel, titanium, and rigid plastics such as PPS and PEEK. Feel free to inquire further about the various material options that can be utilized with precision machining technology.

How can XinYang guarantee tight tolerances?

Our workshop is equipped with top-notch machines for precise CNC milling & turning, EDM, grinding, and various other tools. We maintain a stable temperature using AC to ensure optimal conditions. With our skilled engineers, thorough inspection procedures, and strict quality control measures, we guarantee consistent high quality results, even in challenging situations.