Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence.

This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future.

Inhoudsopgave

What is Quality Testing and Inspection in CNC Machining Applications?

Quality testing and inspection in CNC machining are processes dedicated to verifying that the output meets specific standards of accuracy and integrity. These procedures encompass a range of activities, from dimensional checks to material analysis, ensuring that every CNC machined part aligns with precise specifications.

Why is Quality Testing and Inspection in Machining so Important?

Quality testing and inspection hold the key to maintaining high standards in CNC machining. They prevent defects, ensure customer satisfaction, and maintain the reliability of the manufacturing process.

By ensuring that every component is up to the mark, these processes significantly contribute to the overall success and reputation of the manufacturing industry.

What is the difference between quality control, quality inspection, and quality assurance?

Quality control, inspection, and assurance are three pillars in the world of manufacturing quality management.

Quality control focuses on the operational techniques and activities used to fulfill quality requirements.

Quality inspection, on the other hand, is the act of examining materials or components to ensure they meet specified criteria.

Quality assurance refers to the systematic activities and planning used to provide confidence that a product or service will fulfill quality requirements.

What Are the Key Quality Control Parameters in Machining?

When delving into the realm of CNC machining, understanding the key quality control parameters is pivotal.

This understanding not only enhances your precision in manufacturing but also ensures the delivery of high-quality parts to customers.

Let’s explore these critical parameters that form the backbone of machining quality control.

Dimensional Accuracy and Tolerance

Dimensional accuracy and tolerance are at the heart of CNC machining quality. In your journey as a machinist or a manufacturer, you’ll find that the essence of quality lies in how accurately machined parts meet their specified dimensions.

This accuracy is not just about hitting the right measurements; it’s about adhering to the tight tolerances that define the functionality and integration of parts in their intended applications.

CNC equipment, known for its precision, plays a crucial role in achieving this. Dimensional accuracy isn’t just a measure; it’s a testament to the quality and reliability of the machining process.

Surface Finish and Roughness

Surface finish and roughness significantly impact the performance and aesthetic appeal of CNC machined parts. When you assess a part, the surface finish tells a story of the manufacturing process’s finesse.

High-quality parts often require a smooth finish, free from unwanted ridges or marks, ensuring they perform as intended in their operational environment.

Traditional machining techniques have evolved, allowing for greater control over surface finish, making this parameter a critical aspect of quality control in the machining process.

Material Hardness and Strength

The hardness and strength of materials used in CNC machining are crucial factors that you must consider.

Different applications demand materials with varied hardness and strength levels, influencing the choice of raw materials and machining processes. For instance, a component destined for a high-stress environment will require a material that withstands such conditions without compromising integrity.

Therefore, comprehensive inspection of material hardness and strength becomes an integral part of the quality inspection process, ensuring that the final product not only looks right but performs exceptionally under the intended use conditions.

Geometric Tolerancing

Geometric tolerancing is a sophisticated aspect of CNC machining quality control. It involves the application of specific tolerances on geometric features of a part, such as flatness, straightness, or roundness.

This process goes beyond mere measurement; it’s about ensuring that each part conforms to its geometric specifications, which are vital for the part’s fit, form, and function.

Tools like Coordinate Measuring Machines (CMMs) and practices in geometric dimensioning and tolerancing (GD&T) are indispensable in this realm. They provide the accuracy and precision required to assess and verify complex geometries, ensuring that the parts you produce meet not just dimensional accuracy but also geometric perfection.

Machining Process Control

Machining process control is about maintaining a constant vigil over the entire CNC machining process. This includes:

- Monitoring and Adjusting: It’s essential to continuously monitor aspects like cutting speed, feed rate, and tool wear. In real-time, adjustments are made to sustain the quality of the output. For instance, if tool wear is detected, it may necessitate a change in cutting parameters or even the tool itself to avoid process-related errors.

- Statistical Process Control (SPC): Utilizing statistical methods to oversee and manage the machining processes is key. SPC helps in identifying trends and deviations in the process, allowing for preemptive adjustments. This statistical approach ensures consistency and high quality in every CNC machined part.

Tool Wear and Life

Tool wear and life significantly influence the quality of machined parts. A worn tool can lead to dimensional inaccuracies and poor surface finish. Regular checks and maintenance of tools are essential.

By monitoring tool life and wear patterns, you can preemptively replace or maintain tools, ensuring that they perform optimally throughout their lifecycle, thus maintaining consistent machining quality.

Assembly and Fit

In the assembly and fit phase, the focus is on how individual components come together. Precision in machining ensures that parts fit together perfectly, adhering to the design requirements. This is where aspects like dimensional and geometric tolerances play a significant role.

A comprehensive inspection process is vital here to ensure that each component not only fits but functions as intended in the final assembly.

Environmental Factors

Environmental factors like temperature and humidity can dramatically affect the properties of materials and the precision of machining operations. Controlled environments are often necessary for high-precision tasks.

This includes maintaining the temperature and humidity levels within the machining area to prevent material expansion or contraction, which could lead to inaccuracies.

Compliance with Standards and Regulations

Compliance with industry standards and regulations is an integral part of quality control in machining. This ensures that machined parts are not only of high quality but also safe and reliable.

ISO 9001 Certification

ISO 9001 certification is a global benchmark for quality management systems. It’s a testament to an organization’s commitment to maintaining product quality, enhancing customer satisfaction, and striving for continuous improvement.

AS9100 for Aerospace Industry

Specific to the aerospace industry, the AS9100 standard incorporates all ISO 9001 requirements with additional quality and safety measures.

Compliance with AS9100 is crucial for manufacturers in the aerospace supply chain, emphasizing the importance of quality assurance in every aspect of the machining process.

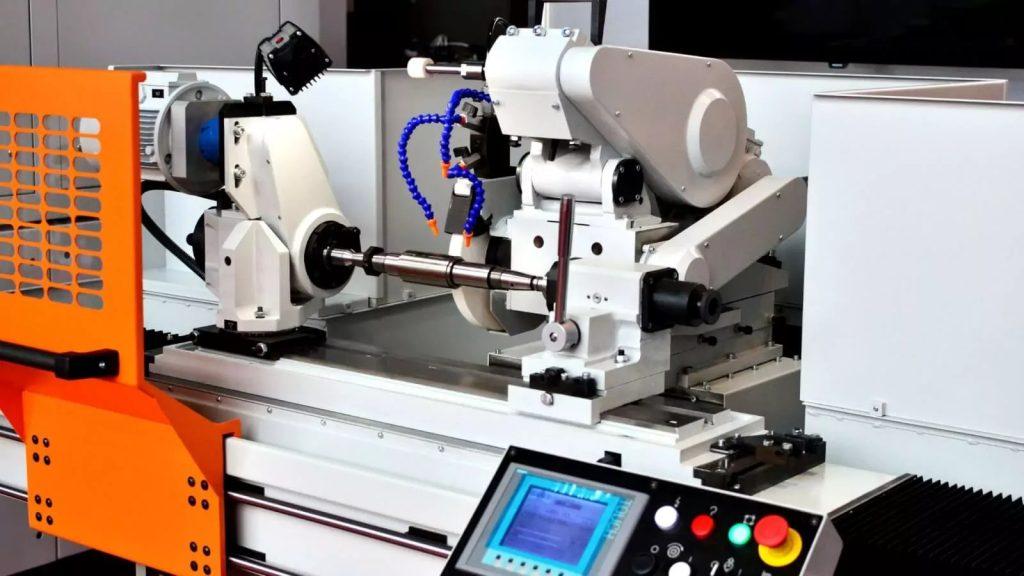

What Techniques and Tools Are Essential for Quality Control in Machining?

To achieve the required precision and quality of the final product, an array of specialized techniques and tools are employed, ensuring each component meets the stringent quality standards demanded in today’s manufacturing landscape.

Let’s delve into these essential tools and techniques that are fundamental to maintaining machining quality.

Dimensional Measurement Tools

Dimensional accuracy is a cornerstone in machining quality control, and achieving this requires precise measurement tools. These include:

- Calipers and Micrometers: These are the quintessential tools in any machinist’s arsenal. Calipers and micrometers provide you with the ability to measure the external and internal dimensions of parts with high precision. Whether it’s a digital caliper measuring a CNC part’s thickness or a micrometer gauging the diameter of a small hole, these tools are indispensable for ensuring parts meet their dimensional specifications.

- Coordinate Measuring Machine (CMM): For more complex geometries, a Coordinate Measuring Machine is key. CMMs offer advanced capabilities to measure intricate and complex geometries with high precision. These machines, equipped with probes, touch or scan the surface of a part to collect data points, which are then used to create a detailed map of the part’s dimensions and geometries. The precision of a CMM is essential in ensuring that parts not only fit together perfectly but also function as intended.

- Gauge Blocks and Thread Gauges: Gauge blocks, also known as Johansson gauges, are used for calibrating measuring equipment and for standardizing measurements across different machine tools and processes. Thread gauges, on the other hand, are essential for ensuring the accuracy of threaded parts – a crucial aspect in many machining projects.

Surface Roughness Testers

The surface quality of machined parts is another critical aspect of machining quality control. For this, surface roughness testers are used:

- Profilometer: A profilometer is a tool used to measure a part’s surface texture or surface roughness. It works by dragging a diamond stylus across the surface of the part, measuring the minute variations in height. This data helps in assessing the quality of the surface finish, which is vital for both the functional and aesthetic aspects of the part.

- Optical Comparators: These are used for a more visual inspection of a part’s surface. Optical comparators magnify the surface of the part, making it easier to detect imperfections and verify surface quality. They are particularly useful in detecting surface defects that might affect the part’s performance or longevity.

Hardness Testing Equipment

The hardness of the material being machined is a critical factor in determining the quality and suitability of a part for its intended application:

- Rockwell Hardness Tester: This is commonly used for measuring the hardness of metals. The Rockwell test assesses the depth of penetration of an indenter under a large load compared to the penetration made by a preload. This method is widely used due to its speed and accuracy in determining material hardness.

- Brinell Hardness Tester: For softer materials, the Brinell hardness test is often employed. It utilizes a wider indenter, which is pressed into the material under a specific load. The diameter of the indentation left in the material is then measured, providing an indication of the material’s hardness.

Non-Destructive Testing (NDT) Methods

Non-Destructive Testing (NDT) plays a critical role in the quality control process of machining. It involves testing methods that do not damage or alter the material or part being tested. Here are some key types of NDT used in machining:

- Ultrasonic Testing: This method employs high-frequency sound waves to detect internal flaws or characterizations in materials. Ultrasonic testing is crucial for identifying issues that are not visible on the surface, ensuring the internal integrity of CNC machined parts.

- X-ray and Magnetic Particle Inspection: These methods are effective for detecting surface and sub-surface defects. X-ray inspection uses penetrating rays to reveal internal structures and flaws, while magnetic particle inspection is used for identifying surface and near-surface discontinuities in ferromagnetic materials.

Statistical Process Control (SPC) Software

In modern machining, Statistical Process Control (SPC) software is indispensable for maintaining consistent quality. It includes:

- Data Collection and Analysis Tools: These tools monitor process stability and control through statistical analysis. By analyzing data collected from various stages of the CNC machining process, these tools help in identifying trends, variations, and potential areas of improvement.

- Real-Time Monitoring Systems: These systems are critical for tracking and analyzing production data in real-time. They enable the identification of trends and deviations, facilitating immediate corrective actions to maintain the quality standards.

Tool Condition Monitoring

Monitoring the condition of tools used in CNC machining is essential for quality control. This includes:

- Wear Measurement Devices: These devices assess tool wear and predict tool life. By accurately gauging the wear of cutting tools, they help in determining the optimal time for tool replacement, thus preventing defects caused by tool degradation.

- Automated Monitoring Systems: These systems are integrated into CNC machines to continuously track tool condition during operation. They provide valuable insights into the performance and efficiency of the tools, ensuring the machining process remains within quality thresholds.

Environmental Monitoring Equipment

One key aspect of quality control in machining is maintaining an optimal environment for machining processes. This includes:

- Temperature and Humidity Sensors: These sensors are crucial in ensuring the machining environment stays within optimal operating conditions. Fluctuations in temperature and humidity can affect material properties and machining precision. Controlled environments, monitored by these sensors, are essential for high-precision tasks, avoiding process-related errors and ensuring consistent quality.

Geometric Dimensioning and Tolerancing (GD&T)

GD&T is a critical system used to define and communicate engineering tolerances. It includes:

- Specialized Gauges and Fixtures: These tools are used for measuring and verifying geometric tolerances of machined parts. They play a vital role in ensuring that the parts meet specific design requirements. This includes checking for flatness, straightness, roundness, and other geometric properties, which are essential for the part’s functionality and fit in the final assembly.

Visual Inspection Tools

Visual inspection remains a fundamental part of the quality control process in machining, involving:

- Magnifying Glasses and Microscopes: For detailed visual inspection of parts, these tools are indispensable. They allow for a closer examination of the surface and structure of the machined parts, detecting any imperfections or deviations from the specified quality standards.

- Borescopes: These are used for inspecting internal features of components that are not visible to the naked eye. Borescopes can be inserted into small openings, providing a view of internal surfaces and helping in identifying any internal defects or inconsistencies.

Material Analysis Equipment

Understanding and verifying the material composition and integrity are crucial in quality control, which involves:

- Spectrometers: These are used for verifying the material composition. By analyzing the material’s elemental makeup, spectrometers ensure that the right materials are used and that they comply with the specified standards.

- Microstructure Analysis Tools: These tools are used for assessing the grain structure and integrity of metals. They help in understanding the material’s properties and predicting its behavior under various conditions, which is crucial for determining its suitability for specific applications.

Assembly and Fit Testing Tools

Ensuring that parts fit and function together as intended is key, involving:

- Go/No-Go Gauges: These are simple yet effective tools for quick pass/fail testing of dimensions. They are essential in verifying whether parts meet the specified tolerances and are particularly useful in high-volume production where quick validation is necessary.

- Functional Testing Rigs: These rigs simulate working conditions to test assembled parts. They are crucial for ensuring that the parts not only fit together but also function correctly under the conditions they will be subjected to in their actual use.

Documentation and Traceability Systems

Maintaining records and traceability is integral to quality control, which includes:

- Quality Management Software: This software is used for maintaining records of inspections, tests, and compliance with standards. It ensures that all quality control processes are documented, providing traceability and accountability, which is crucial for continuous improvement and meeting regulatory requirements.

What are all machining quality testing and inspection stages?

The stages below are essential to ensure that machined parts meet the highest quality standards before they are used or shipped to customers.

Raw Material Inspection

Raw material inspection is the first and fundamental step in the machining process. It involves meticulously checking and assessing the quality and properties of the materials before commencing any machining operations.

This step is crucial as the quality of the raw material significantly impacts the final product’s quality. During raw material inspection, manufacturers verify that the materials meet the required specifications in terms of composition, hardness, and other relevant properties.

First Article Inspection (FAI)

First Article Inspection, often referred to as FAI, is a critical quality control process. It serves as a preliminary check to ensure that the initial produced part aligns with design and quality requirements.

Manufacturers examine the first article produced in a production run to confirm that it meets the specified dimensional and functional criteria. FAI is essential to identify and rectify any issues early in the production process.

In-Process Inspection

In-process inspection involves conducting inspections at various stages of the machining process. The goal is to monitor dimensions, tolerances, and surface finish continuously.

This real-time monitoring helps identify and correct issues as they arise, preventing the production of defective parts and reducing the need for rework.

Dimensional Inspection

Dimensional inspection is a meticulous process that uses precision measuring instruments such as calipers, micrometers, and gauges to verify that the dimensions of machined parts align with design specifications. Maintaining dimensional accuracy is critical to ensure that the final product functions as intended.

Surface Finish Inspection

Surface finish inspection evaluates the surface roughness and finish of machined parts. This inspection can be performed using specialized tools like surface roughness testers or through visual inspection. Achieving the specified surface finish is essential for both functionality and aesthetics.

Visual Inspection

Visual inspection is a crucial step in quality control. It involves a thorough visual examination of machined parts to detect surface defects, cracks, burrs, scratches, or any imperfections that may impact their quality or functionality.

Non-Destructive Testing (NDT)

Non-destructive testing techniques, including ultrasonic testing, magnetic particle testing, dye penetrant testing, and radiographic testing, are employed to detect hidden defects within machined parts without causing any damage.

NDT is especially valuable for identifying internal flaws that may compromise the part’s integrity.

Hardness Testing

Hardness testing is used to measure the hardness of materials, ensuring they meet specified hardness requirements. Techniques such as Rockwell, Brinell, or Vickers hardness testing are employed to assess material hardness accurately.

Functional Testing:

Functional testing assesses the machined part’s functionality, including its fit, form, and performance within the intended application. This stage ensures that the part functions as expected.

Assembly and Fit-Up Inspection:

Assembly and fit-up inspection verify the fit and alignment of machined components during the assembly process. This is essential to ensure that the final product functions correctly and that tolerances are within acceptable limits.

Final Inspection

Final inspection is a comprehensive evaluation of fully machined parts. It ensures that all quality standards and specifications are met before the parts are released for use or shipment. This stage is critical for delivering high-quality products to customers.

Statistical Process Control (SPC)

Statistical Process Control (SPC) techniques are used to monitor and control the machining process, ensuring it remains within acceptable limits and minimizing variations. SPC helps maintain consistency and quality throughout production.

Documentation and Record Keeping

Maintaining detailed records of all inspections and testing results is essential for traceability and quality control.

Proper documentation ensures that the manufacturing process complies with quality standards and provides a valuable reference for future quality assessments.

Post-Machining Treatments:

In cases where post-machining treatments like heat treatment or plating are applied, inspection is crucial to verify that these treatments meet specified requirements. This ensures that the treated parts meet quality standards.

Packaging and Shipping Inspection:

The final step involves checking the quality and condition of machined parts before packaging and shipping to customers. This inspection prevents any damage during transit, ensuring that customers receive products in optimal condition.

How Crucial is Personnel Training in Machining Quality Control?

The role of skilled personnel in machining quality control cannot be overstated. Well-trained staff are essential for operating any complex CNC machine tool and implementing quality control procedures effectively. They bring an understanding of the nuances of machining processes and can swiftly adapt to changes, ensuring consistent quality in production.

Training programs focusing on the latest machining techniques, quality standards, and inspection processes are vital in upskilling personnel to meet the dynamic demands of CNC machining.

How do we conduct quality inspection and assurance at XinYang?

At XinYang, our commitment to delivering precision in our CNC machining services and parts is backed by a comprehensive quality inspection and assurance process.

This process is meticulously designed to ensure each project not only meets but exceeds your requirements. Let’s delve into our inspection and testing procedures.

- Cutting-Edge Measuring and Testing Equipment: We leverage the latest in technology for our quality control system. This approach covers the entire manufacturing process – from incoming materials inspection to the final inspection and testing before shipping.

- X-RAY Material Tester: With this advanced tool, we identify all kinds of metal within 30 seconds. This rapid identification guarantees the correct material usage, preventing potential losses in mass production and ensuring safety in prototype testing.

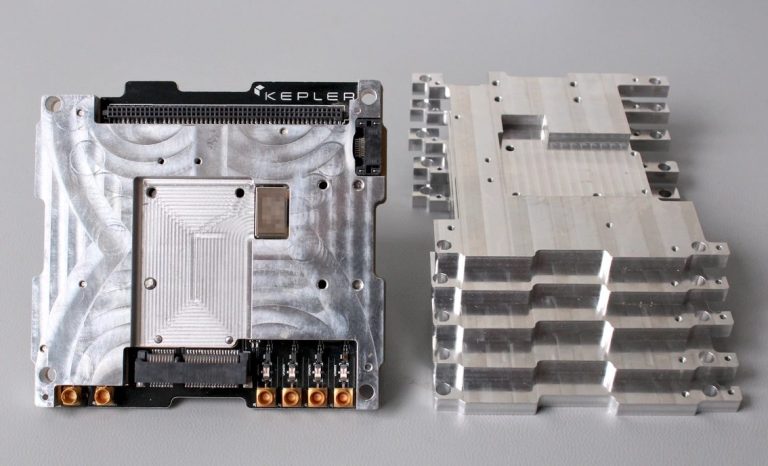

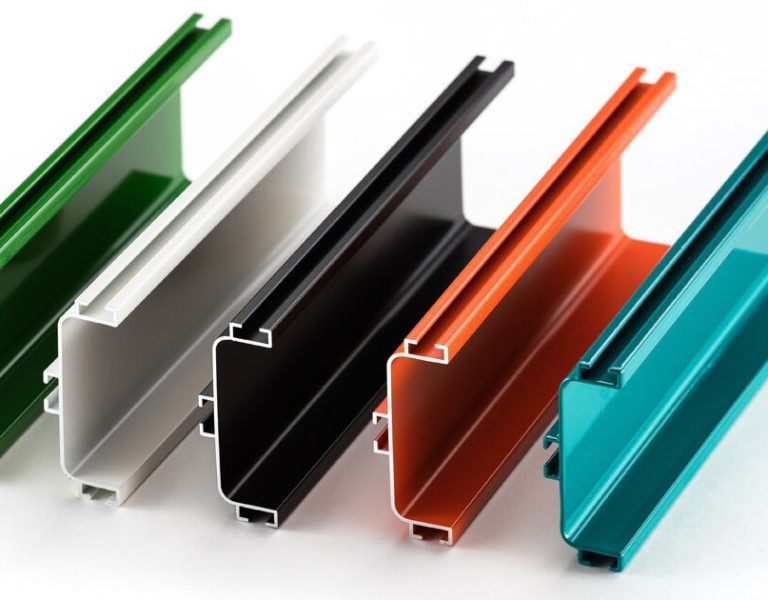

- On-Machine Inspection System: This system enhances the precision and speed of finding material block positions, especially beneficial for post-machining on inconsistent die casting parts or extrusion profiles. It also adjusts cutting paths automatically based on inspection results, saving both time and cost.

- Projector: Our projector is equipped to measure various geometrical features with high accuracy. It’s integrated with data processing functions, exporting measurement data directly for statistical analysis. This tool is particularly useful for ensuring the straightness of workpieces.

- Coordinate Measuring Machine (CMM): The CMM allows us to define the parameters of complex shapes through a series of points in three-dimensional space. This device is crucial for ensuring the parts conform to their designed geometries with a high degree of accuracy and repeatability.

At XinYang, our quality assurance starts from the very beginning and is embedded in every step of the manufacturing process.

By utilizing state-of-the-art equipment and systematic inspection procedures, we ensure that every CNC machined part you receive is of the highest quality, meeting both your specifications and industry standards.

Conclusion

maintaining high standards in machining quality control is a multifaceted endeavor, involving a blend of sophisticated tools, advanced techniques, and skilled personnel.

The challenges in this field are significant, yet with targeted solutions and best practices, they can be effectively addressed.

Staying ahead in this competitive domain requires a commitment to quality at every stage, from design to final inspection, ensuring that each machined part meets the exacting standards of precision and excellence.