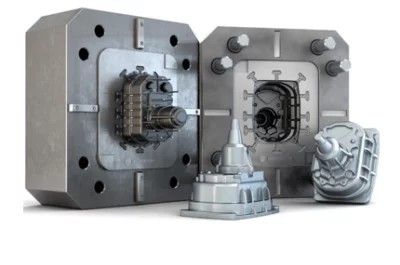

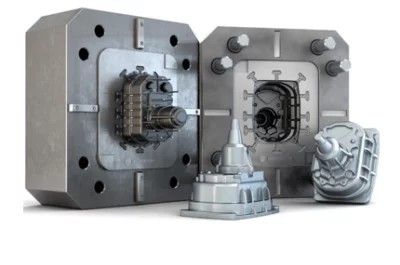

Short-Run & Mass Production Mold Making Services

One-Stop Mold Making Supplies for All Your Project Needs

Are you in need of mold making supplies for mass production parts? XinYang is renowned as the top mold maker in China. With our in-house mold making facilities and access to resources from our partners, we have the capability to provide plastic injection molds for rigid plastics and rubbers, metal injection molds for precision stainless steel parts, and pressure die casting molds for aluminum, magnesium, and zinc. Whether you require low-cost local production molds or high-quality exported molds, we can cater to all your project requirements.

XinYang is capable of handling prototype molds for short-run production as well as mass production molds for millions of shots, ensuring a smooth process for all your needs.

Inhoudsopgave

Our Advantages of Mold Making Services

XinYang stands as a seasoned mold making service provider, offering a plethora of advantages that set us apart from our competitors.

1. Fast DFM reports

While we ensure the feasibility of your design during the quotation process, we are also capable of delivering a comprehensive and efficient DFM (design for manufacturability) report prior to commencing production. Within this report, we will pinpoint any errors or concerns that could potentially lead to manufacturing complications in the future.

2. Wide range of molds

We provide a variety of molds to cater to your specific needs, enabling you to avoid any disruptions in your projects. Simply entrust us with all your requirements to ensure a seamless execution of your project.

3. Fast Turnaround

Our extensive facility and machining capabilities enable us to expedite mold construction, regardless of the application or material, resulting in faster completion of your moldings.

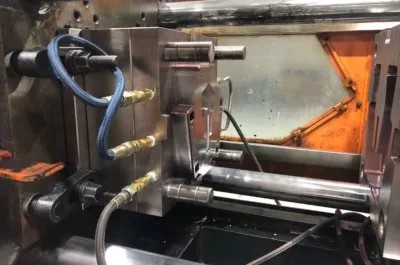

4. Molding Capabilities

XinYang has the capability to ship your molds directly to you, in addition to providing injection molding and other production services for the delivery of prototypes and final parts manufactured with those molds.

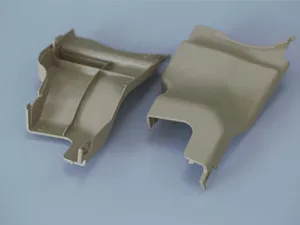

See why our customers love us

Every quarter, we order approximately 20 sets of plastic enclosures for our device from XinYang The enclosures were initially made by urethane casting, but Ronan came back to me with the idea of using an aluminum mold, which allowed me to get a few hundred moldings. We decided to move to this process. The T1 samples weren’t good enough, as we got some shrink marks, but this was quickly sorted out when we received the T2 samples.

Although we had to invest more for the mold, we now save 70% compared with urethane casting, and we can use UV-resistant ABS to keep the color stable. Overall, I am very happy with the solution.

Christian

Design Engineer

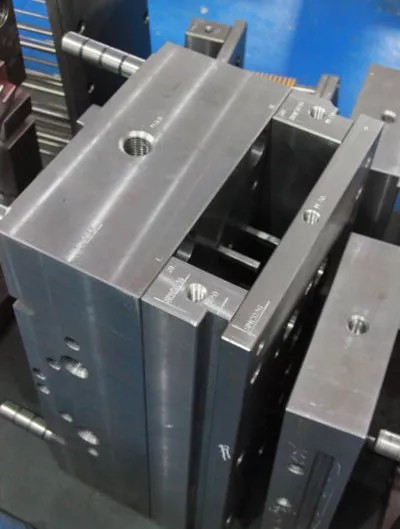

Mold Making Processes

Mold making is a complex process that requires a high level of skill and experience. Although each case is different, a typical order for a set of molds may go something like this:

Types of Molds We are Offering

Plastic Injection Mold

Plastic injection molds are molds made of either aluminum or steel, which are utilized to manufacture various parts using a diverse selection of plastics such as nylons, acrylics, elastomers, and reinforced materials like glass-filled polyamide. The longevity of custom plastic molds can range from 100,000 to 1,000,000 shots.

Mold for Investment Casting

By utilizing 3D printing technology, we have the capability to create cost-effective investment casting molds. This involves the creation of a wax pattern, which is then encased in ceramic material. These ceramic molds are subsequently employed in the production of metal cast parts, including aluminum, zinc, magnesium, stainless steel, and various other metals.

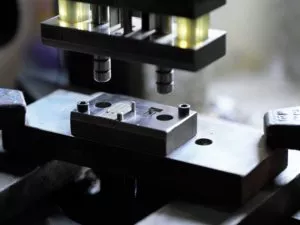

Metal Injection Mold

Metal injection molding (MIM) utilizes a metal and binder mix as feedstock in the injection molding process. Typically, a metal injection mold is crafted from tool steel to endure the metal injection, although aluminum can also be employed.

.

Extrusion Mold

Our metal die molds are suitable for aluminum extrusions using alloys such as 6061 and 6063. Additionally, we manufacture molds for plastic extrusions using materials like polystyrene, nylon, polypropylene, and polyethylene.

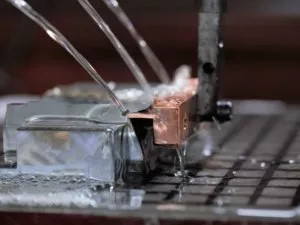

Die Casting Mold

In contrast to numerous experts in prototyping, we possess the capability to offer metal casting molds (along with a low-volume casting service in collaboration with our partners). These molds, which are usually crafted from durable steel, enable the production of components using aluminum, zinc, magnesium

Sheet Metal Mold

We possess the expertise in fabricating sheet metal molds for stamping and bending, enabling us to produce sheet metal prototypes.

Mold Making Projects

XinYang, situated in China, is a reputable mold manufacturing enterprise that provides an extensive selection of prototype molds and production molds for various production techniques. These techniques encompass plastic injection molding, metal injection molding, high pressure die casting, metal casting, profile extrusion, and sheet metal fabrication. Our proficient team of engineers and manufacturers has achieved remarkable milestones, having manufactured over 5,000 molds and delivered more than 1 million parts to our valued customers.

Protect Glasses Mold

This 4-cavity mold was created specifically for PU glasses injection molding in order to safeguard individuals from infection during this crucial period. The mold was completed in just 10 days, a significant improvement from the usual 4-week timeframe. Discover the methods we utilized to accelerate the mold production process.

Big Car component Mold

We have the capability to produce molds of large sizes using our CNC and EDM machines, and we can efficiently carry out the molding process with our 1500 ton molding machines.

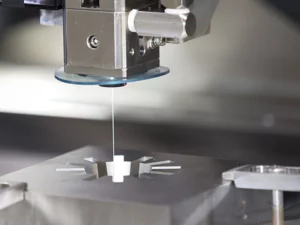

Reflector Mold Core

In order to obtain optimal outcomes for optical components through the injection molding process, it is crucial to attain a high-gloss mold core by means of High Speed CNC Machining, rather than relying on manual polishing.

Mold Making FAQ

What is mold making and when do you need it?

Molds are normally created to duplicate plastic and metal parts. After testing the prototypes and the market, it is the most cost-efficient way to launch your products at scale.

Should I choose a locally produced mold or an exported mold?

Generally speaking, making plastic or metal molds (and moldings) is cheaper in China than other countries. But shipping costs should also be considered: you will need to use air freight if you have a tight schedule; sea freight is much cheaper, but will usually take 40 days or more.

How long does a mold last?

A well-made, fully harden steel mold may be used for up to a million shots or injections, depending on the mold shape and injection material. Aluminum molds are less durable, which is good for short-run production with tight schedule.

Can molds be any shape?

Molding designs should avoid sharp corners, inconsistent wall thicknesses, and other features that restrict material flow.

When do I need full automatic mold?

Whatever you decide to use, in the end, what is the best cost-efficient way to get your parts done in the required quality is the key.