Inhoudsopgave

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Launching a satellite into orbit poses a significant challenge, particularly when attempting to achieve this goal within a 12-month timeframe, while adhering to a tight budget, and doing so for the very first time.

The breakdown

Company:Kepler Communications

Location:Toronto, Canada

Technology:Telecommunications

Material:Aluminum 6061, Aluminum 7075

Product:Nanosatellites

Why Protolabs Network?:Most price competitive and lead times as fast as 5 days

The result:Their first satellite successfully launched and now in orbit

Written by George Fisher-Wilson

Published on May. 29, 2018

Launching a satellite into orbit poses a formidable challenge, particularly when attempting to accomplish it within a 12-month timeframe, while adhering to a stringent budget and undertaking the endeavor for the very first time.

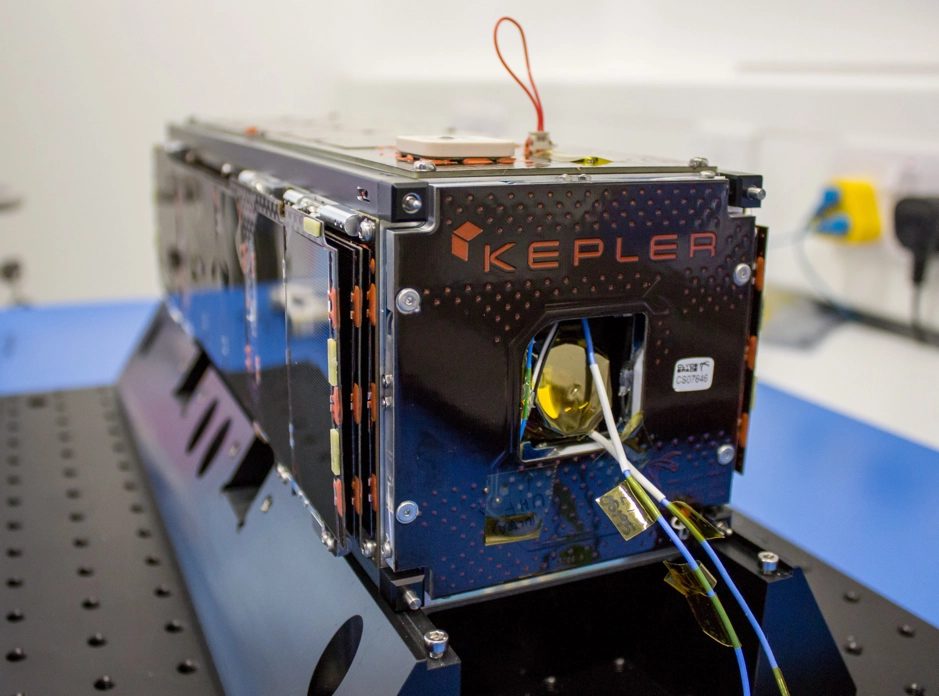

Kepler accomplished the feat of transforming a mere napkin sketch into a fully operational nanosatellite within a year, thanks to the efforts of the Toronto-based team. This milestone made Kepler the pioneer in launching and effectively managing a LEO communications satellite in Ku-band, a frequency range known for its ability to transmit substantial data volumes at a minimal expense.

The Company

In 2015, Kepler Communications was established by four graduate founders hailing from the University of Toronto. The following year, they became part of the startup accelerator Techstars Seattle, securing $5M in seed funding. Fast forward to 2018, they have achieved a significant milestone by successfully deploying their inaugural satellite into orbit from a location in China, with plans for a second launch later this year.

Kepler’s primary objective is to establish an affordable in-space communication network for assets in outer space. The company is focused on creating a space infrastructure that can offer connectivity to various satellites, enabling real-time command and control via its constellation of low-earth orbit (LEO) satellites.

Currently, the cost of satellite connectivity is exorbitant for remote businesses operating in sectors like maritime, mining, agriculture, and oil & gas. Additionally, numerous remote operations face the challenge of limited access to fiber or cellular services, leaving them with no alternative but to rely on conventional satellite methods for data transmission.

Kepler’s expanding constellation enables the provision of a worldwide satellite data backhaul service, utilizing the capabilities of its initial satellites. This service, known as store-and-forward, facilitates satellite communication by enabling geographically dispersed operations and teams to share extensive multimedia files through a media vault updated via satellite. Additionally, it enables the transfer of substantial amounts of scientific data, such as astronomy, seismology, weather, and other data collected from the most remote areas on Earth.

Trial and Engineer

Kepler faced a significant hurdle in locating a manufacturing collaborator capable of matching the pace of iteration. Additionally, it was crucial for this partner to offer manufacturing services throughout all phases of the design cycle. During a conversation with Adam Latour, the Lead Product Engineer, and Jared Bottoms, the Lead Systems Engineer, they elucidated their swift design and manufacturing procedure.

“We utilize a combination of methodologies for development. Commencing with a broad system that we intend to employ, we proceed to outline the structure to obtain a general understanding, which establishes our fundamental requirements. Subsequently, we delve into the initial design, construct it, and conduct an analysis. This iterative process is then repeated through a series of trials and engineering adjustments until we achieve a component that instills us with the assurance that it will function as intended.”

Keeping up with Kepler

Kepler Communication’s strategy involves creating rapid initial prototypes of innovative concepts and promptly iterating to fail fast and progress forward. As the development progresses, Kepler must transition from sourcing parts made of prototype-grade materials to high-quality space-grade materials. Leveraging the Protolabs Network enables them to receive parts within a week of submission. Jared elaborates:

Should a test part demonstrate outstanding performance, we remove it from the design cycle and proceed with it immediately. This is why platforms such as Protolabs Network are essential, as they allow us to quickly create and test prototypes, enabling us to seamlessly transition to the manufacturing stage. With the ability to easily request quotes by uploading a STEP file, we can efficiently source the necessary parts for the next phase of production.

Quotes in 2 seconds instead of 2 weeks

Given the urgency of the situation, the conventional process of obtaining a quotation was no longer sufficient. Through the Protolabs Network platform, one can swiftly obtain pricing information for a diverse range of CNC machining materials, simplifying the process of cost and lead time evaluation. Adam elaborates on their previous approach to acquiring quotations.

“The process of placing an order on Protolabs Network is ideal for engineers with limited time. It is efficient and eliminates much of the initial work required. I received a fair quote for my first order within 30 minutes, and now I can even receive instant quotes for specific materials. Previously, setting up an order would take a week or two, but now everything is streamlined into a single online process. The speed of quotation does not compromise the price, as there are no machinists providing overly cautious estimates when quoting quickly.”

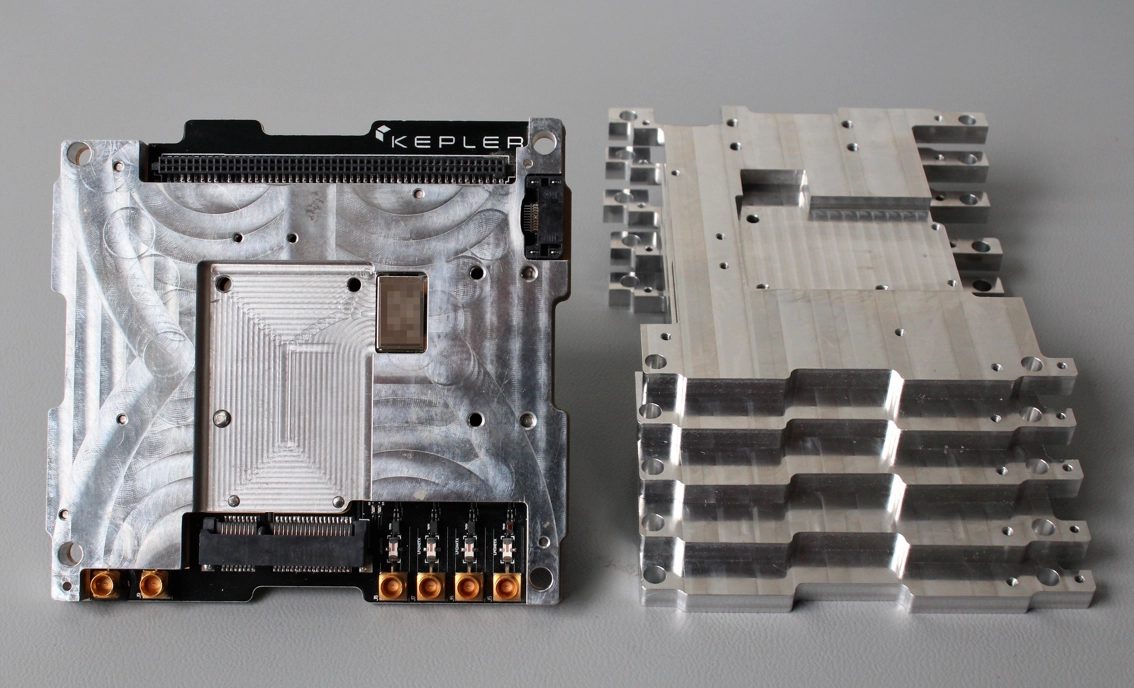

From rapid prototypes to parts in space

Protolabs Network has manufactured a range of components for Kepler Space, showcasing their application and finish. The manufacturing process employed was CNC machining.

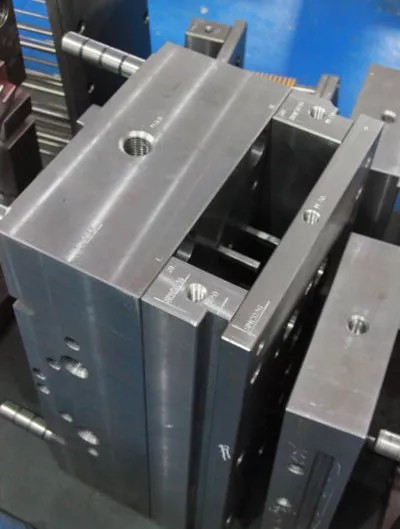

Rear bracket prototype

This bracket was part of an initial design phase for one of the earliest satellite models. It was constructed from aluminum 6061 and later coated with a black anodized finish.

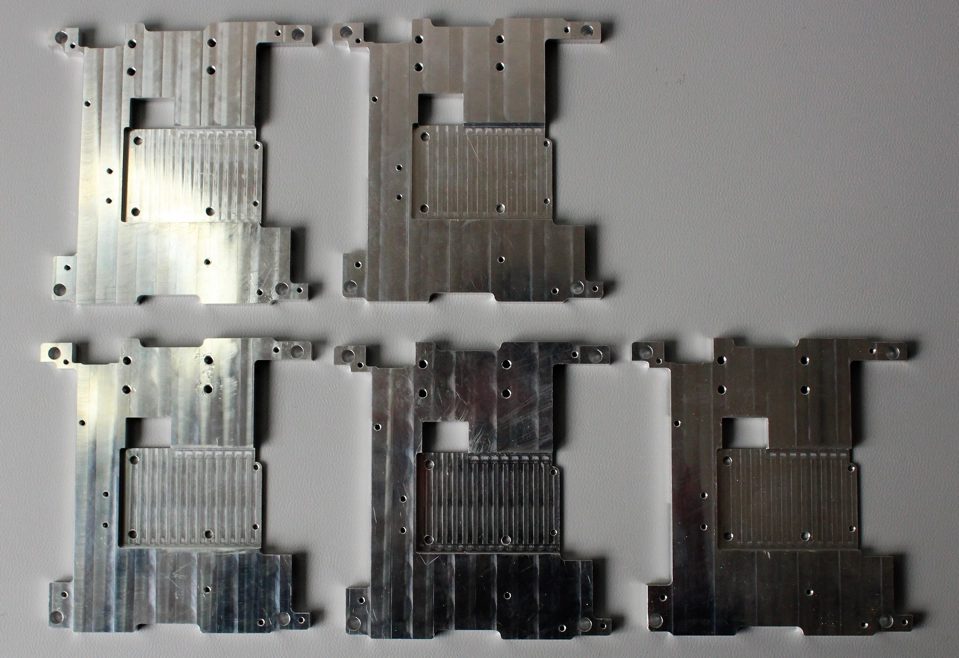

Shield

This component was ultimately utilized on the spacecraft. It serves as a heat shield designed to manage surplus heat from an external origin through dissipation, reflection, or absorption. Positioned on the left is the second version of the SDR shield, accompanied by five additional versions. The material employed was Aluminum 7075 coated with Alodine 1200.

Mega constellations and beyond

The Kepler Space team has excelled in establishing efficient part development procedures, enabling them to innovate rapidly alongside a skilled team. By continuously learning from each iteration, they are able to create and engineer simultaneously. As a result of this process, they successfully launched their first nanosatellite into orbit, paving the way for additional satellites to be added to their constellation.

Protolabs Network played a crucial role in mitigating the risk associated with sourcing for Kepler Communication’s engineers. By providing a platform for quick part sourcing and ensuring reliable quality, engineers are able to save valuable time. This allows them to focus on developing new components and supporting Kepler in their mission to establish a mega constellation that will serve as the vital link connecting Earth to space.