die casting complete guide

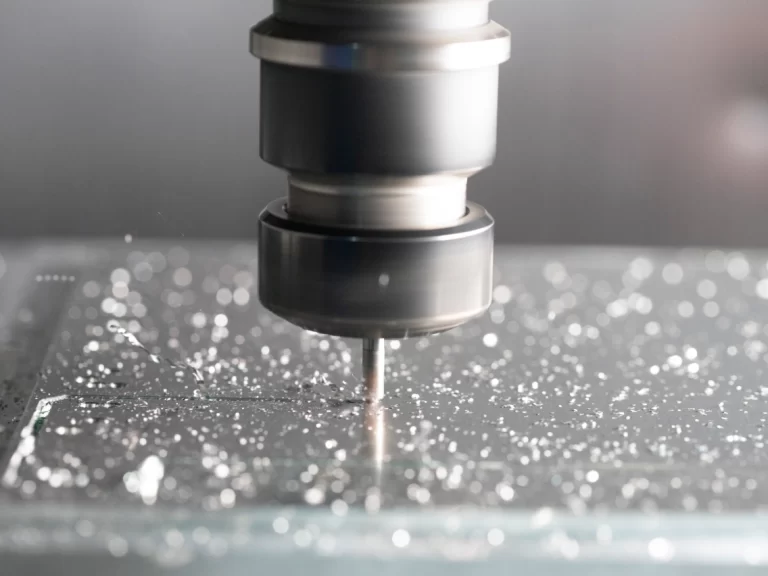

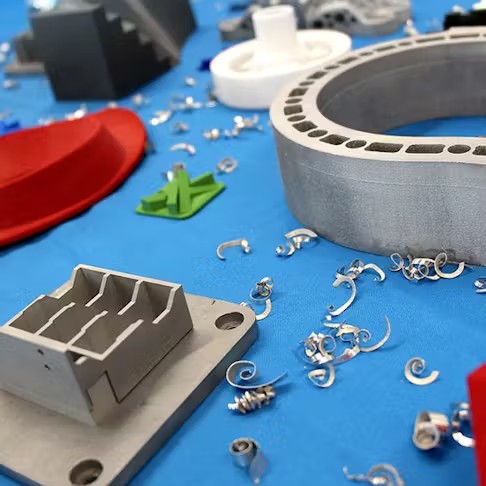

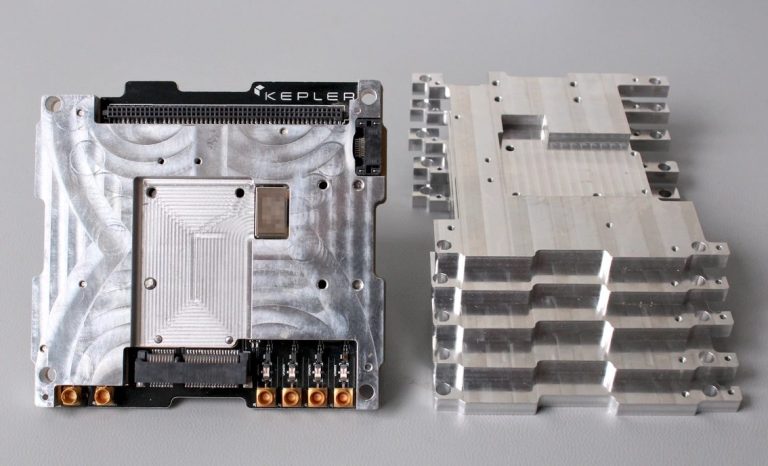

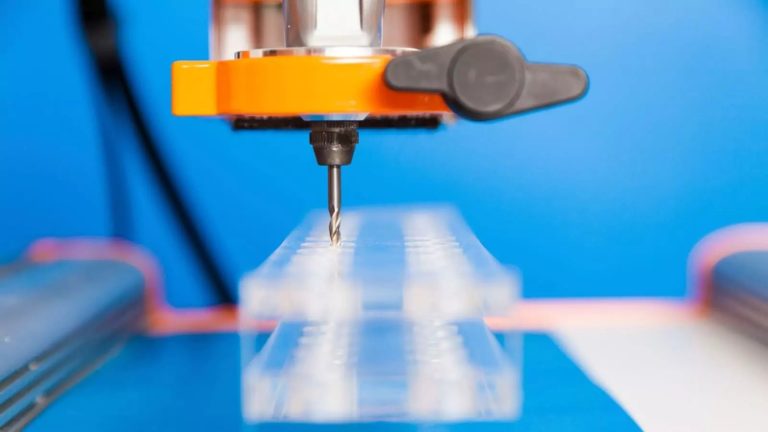

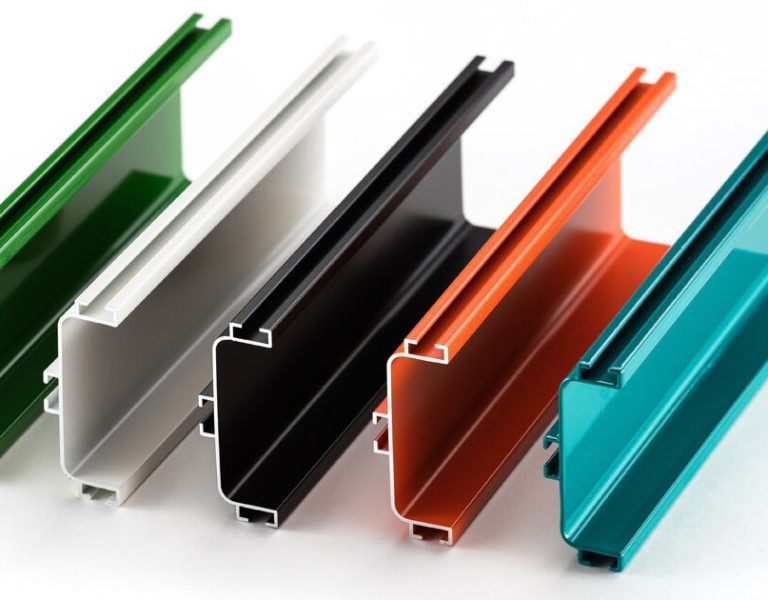

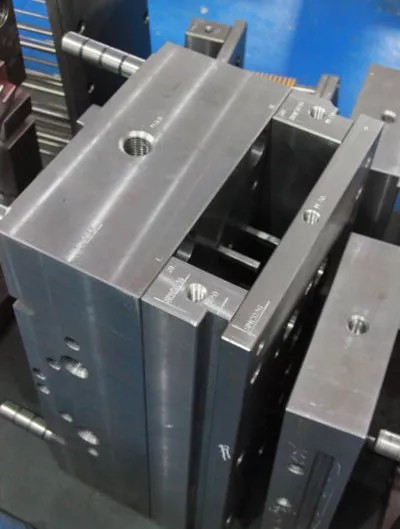

die casting complete guide When it comes to “die casting”, we can think of that it’s an innovation and high-efficiency technology in manufacturing, It’s definitely a key word that cannot be ignored by us. As an efficient metal manufacturing method, die casting technology has been widely used in different industries,…