Table of Contents

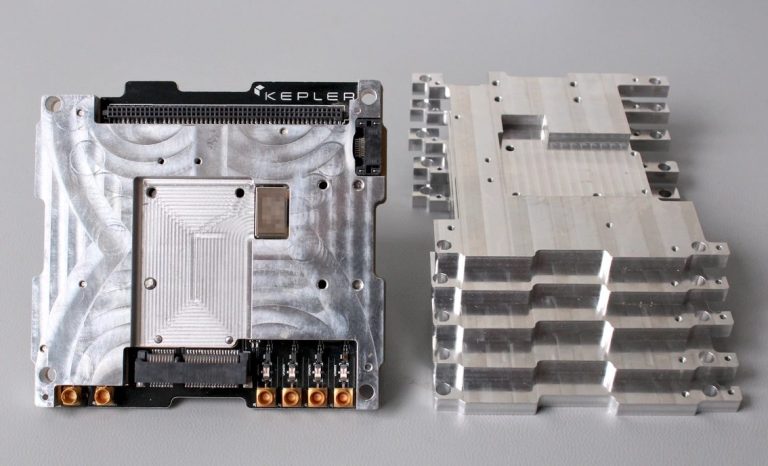

Low-Volume Metal Casting Services

Aluminum, Magnesium, Zinc & Steel

One-off prototyping or 1000+ production parts

During the process of delivering prototypes to our customers, we often encountered inquiries regarding the availability of low-volume metal casting services. As a result, we initiated a search for metal casting suppliers to cater to these specific requirements. Regrettably, this quest proved to be quite exasperating. The larger casting companies displayed no interest in undertaking low-volume production, while the smaller ones were unable to meet our stringent quality standards. Despite the challenges we faced, we perceived this situation as a potential business opportunity. Recognizing the difficulty we experienced in locating suitable companies for these projects, we understood that overseas customers would encounter even greater obstacles in their search.

Over the course of two years, we have managed to establish fruitful connections with several medium-sized casting partners who possess the capability to fulfill our stringent quality standards and time constraints. As a result, we are now equipped to provide high-pressure die casting services in aluminum, magnesium, and zinc, along with investment casting in brass and various steel alloys.

.

Why use XinYang for Metal Casting?

It might sound counterintuitive to use a RP company for metal casting services, but we offer very good reasons for doing so:

- We have built up an excellent relationship with our partners for pressure die casting and investment casting.

- We have a huge amount of precision CNC machines for post-machining

- With our project management experience, we can guarantee a smooth transfer of information and punctual delivery.

Common Sheet Metal Applications

- Aluminum

- Sandblasting

- Powder coating

- Zinc

- Polishing

- Magnesium

- Plating

- Steel

- Painting

What is

Pressure Die Casting?

Pressure die casting is a metal casting technique that bears resemblance to injection molding. In this process, molten metal is forcefully injected into a mold cavity to produce metal parts. At XinYang, we employ certified machinery and pressure casting dies to shape your designs using molten metal, typically zinc, copper, aluminum, magnesium, lead, pewter, or other tin-based alloys. Our pressure die casting process is highly efficient and dependable, offering substantial cost savings. With our adaptable approach, we can cater to your project requirements, whether it involves small batches of 50 or as many as 1,000 pieces.

- Cost efficiency per unit is achieved during extensive manufacturing runs

- Superior surface quality and consistent dimensions

- Elaborate shapes can be produced without the need for extensive post-machining

- Ideal for medium to large components that may require more time and cost to be machined

Metal Casting FAQ

Why use casting instead of a more accessible process like CNC machining?

Metal casting is a viable method for producing large components that possess exceptional tensile strength and intricate designs featuring undercuts. In certain cases, there may be no substitute for this process

How is it economically feasible for XinYang to offer low-volume metal casting?

We possess a consortium of dependable casting collaborators who meet our casting requirements, and we employ cost-effective 3D printed wax patterns to diminish the cost for the clientele

Can you combine casting with other techniques?

We possess expertise in CNC machining additional elements (such as engraving and intricate details) onto cast components.

Is there a minimum order quantity?

Metal casting orders of less than 10 units are typically not accepted by our company

Start Your Project With A Free Quote