Table of Contents

die casting complete guide

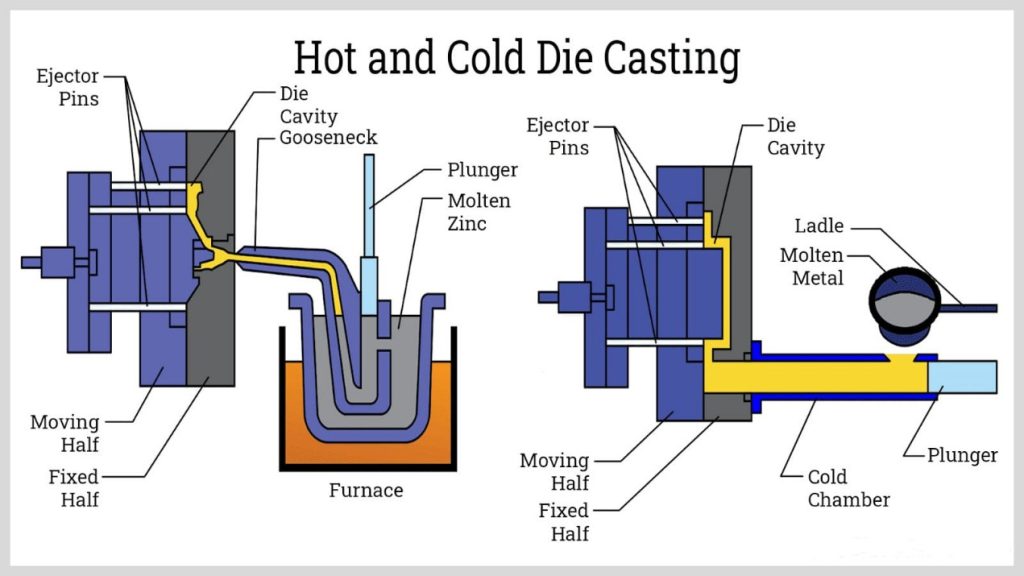

When it comes to “die casting”, we can think of that it’s an innovation and high-efficiency technology in manufacturing, It’s definitely a key word that cannot be ignored by us. As an efficient metal manufacturing method, die casting technology has been widely used in different industries, and continues to promote the progress of product design and production.

Technical background

Die casting is a manufacturing process that produces parts by melting metal material into a metal mold at high pressure. The advantage of this method is that it enables the production of complex shapes quickly and precisely at a relatively low cost. Mold is usually made of wear-resistant tool steel that can bear high pressure and high temperature environments.

Application field

Die casting technology is widely used in automotive, aerospace, electronic parts, household appliances and other industries. For example, in automotive manufacturing, engine components, transmission housings and brake system parts are often manufactured by die casting processes because these parts require high strength and precise shape.

Strengths and challenges

Mainly advantages of die casting include high productivity, the ability to manufacture complex product shape, and excellent surface quality and dimensional accuracy. However, challenges associated with this include the high cost of mold manufacturing, long cycle times, and the complexity of handling certain alloys at high temperatures.

Technological improvement

With the development of material and manufacturing technology, die casting technology continues to evolve. Modern die casting processes combine computer-aided design (CAD), mold flow analysis and automated control systems, resulting in significant improvements in production efficiency and high quality part.

Sustainability and future prospects

In the context of the pursuit of sustainable development, die casting technology is also constantly evolving to reduce energy consumption and wasting of material. In the future, with the application of new materials and the improvement of the process, die casting technology is expected to further expand its application field and play a greater role in industrial manufacturing.

In conclusion

Die casting is an efficient and accurate metal processing technology, not only promotes technological progress in various industries, but also brings new possibilities for product design and manufacturing. As technology continues to advance and application areas expand, die casting technology will continue to play an important role in manufacturing.