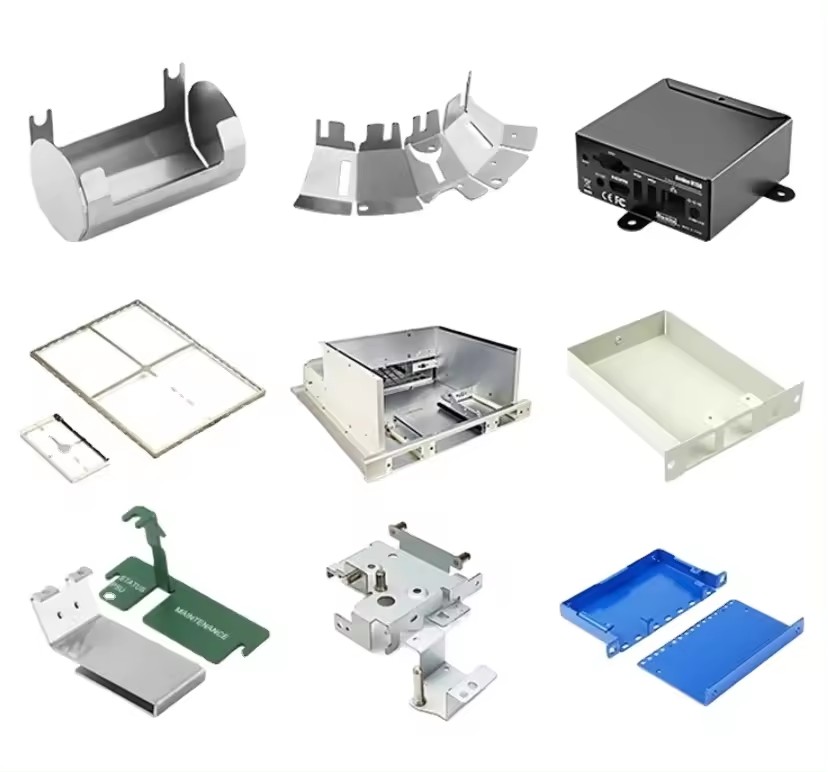

Precision 5-axis CNC milling is utilized for the machining of stainless steel, brass, aluminum, and titanium parts, as well as CNC turning mechanical components

Key attributes

Industry-specific attributes

CNC Machining or Not:Cnc Machining

Material Capabilities:Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

Other attributes

Place of Origin:Guangdong,DongGUan,China

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid PrototypingMicro Machining or Not:Not Micro Machining

Brand Name:XinYang

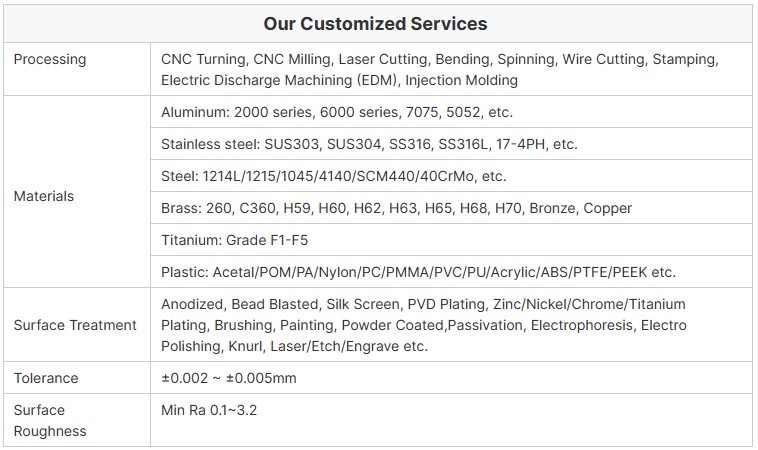

Color:Customized Color

Size:Customized Size

Material:According to customer demand

Micromachining or not:Not

Tolerance:0.003 mm -0.01 mm

Surface finish:According to customer demand

Precision machining range:Turning, milling, drilling, grinding, line -EDM cutting, etc

Equipment:CNC Machining Centres

Main Prosess:CNC turning / CNC milling

Application:Medical/Aerospace/Electronics /Automotive/ industries/Watch/Office

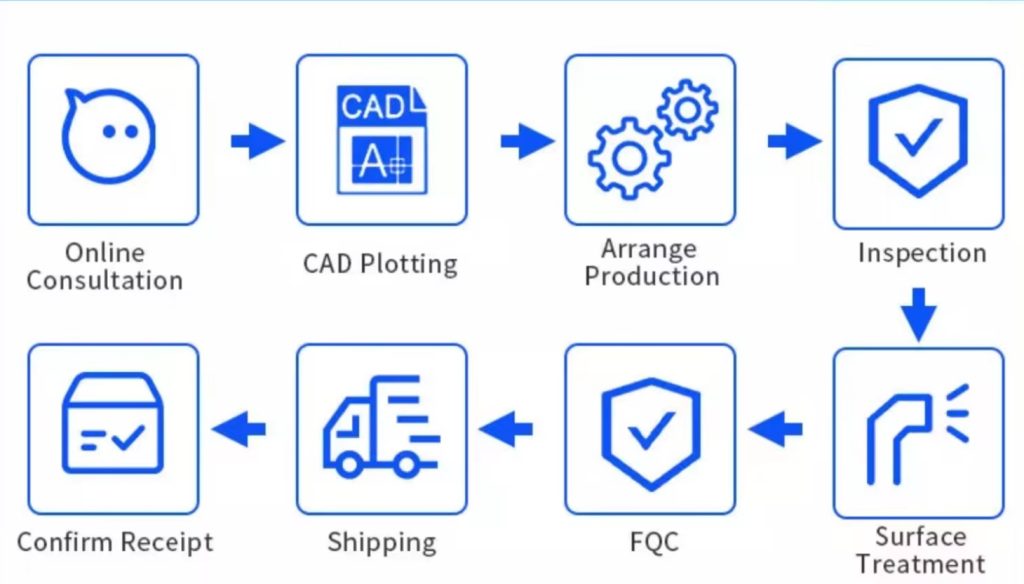

FLOW CHART

Automated Processing

Automated Processing

The utilization of various CNC equipment enables the meticulous processing of multiple components, thereby enhancing the precision and efficiency of mold manufacturing

The Particulars Were Effectively Managed

The surface is sleek and polished, radiating a brilliant and exquisite appearance, evoking a profound sense of artistry!

Rounded And Sleek Edges

The side fish’s details have been meticulously handled, ensuring a seamless and polished finish. Every aspect exudes a high level of quality, even in the smallest of details

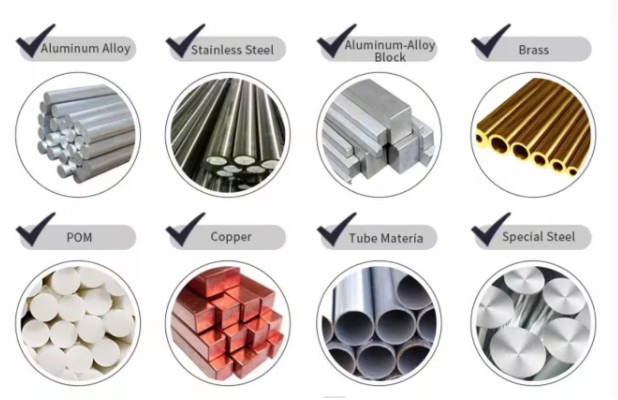

MATERIAL AVAILABLE

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.