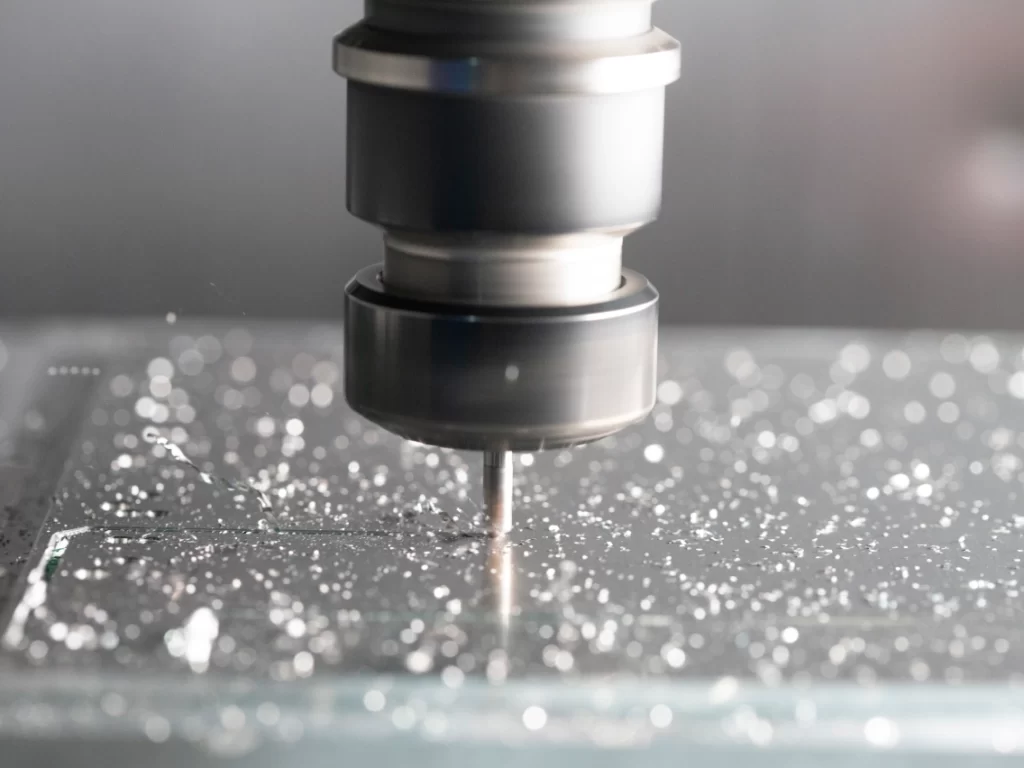

CNC milling service

Acquire bespoke components from our pool of expert CNC milling suppliers. Obtain custom CNC milling components crafted from over 50 various metals and plastics, offered in more than 15 surface finishes. Achieve tolerances as precise as ±.0008″.

What is CNC milling?

CNC milling is a manufacturing process that utilizes rotational cutting tools to eliminate material from a workpiece in order to create finished parts and products. This method is suitable for a wide range of materials, such as metals, polymers, wood, and glass. Typically, CNC milling systems are equipped with 3 linear degrees of freedom: the X, Y, and Z axis, enabling exceptional precision and intricate detailing. For more advanced capabilities, Protolabs Network offers 5-axis systems that include additional rotational movement for the tool head and machining bed (A and B axis). With 5-axis CNC machines, complex parts can be produced with high precision without the need for multiple machine setups.

The maximum size of the part for CNC milling in 3- and 3+2-axis is determined

There are several types of CNC milling machines, each with its own distinct maximum part size. 3-axis and 3+2 axis machines have the lowest start-up costs and can produce parts with relatively simple geometries.

Milling in three axes

| Size | Metric measurements | Imperial measurements |

|---|---|---|

| Maximum size limit for soft metals [1] and plastics. | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm. | 78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in. |

| Maximum portion for hard metals [2]. | 1200 x 800 x 500 mm. | 47.2 x 31.4 x 19.6 in. |

| Minimum feature dimension. | Ø 0.50 mm. | Ø 0.019 in.. |

| Aluminum, copper, and brass. |

Milling with a 3+2 axis configuration

| Size | Metric measurements | Imperial measurements |

|---|---|---|

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

| [1] Aluminum, copper & brass [2] Stainless steel, tool steel, alloy steel & mild steel |

Largest component size for 5-axis CNC milling

5-axis machining centers, the most advanced within the milling machine category, have the capability to manufacture parts with intricate geometries. Due to their efficiency in requiring fewer machine setups, these machines are highly productive.

| Size | Metric measurements | Imperial measurements |

|---|---|---|

| Maximum part size for all materials | 2000 x 1500 x 200 mm | 78.7 x 59.0 x 7.8 in |

| Minimum feature dimension | Ø 0.50 mm | Ø 0.019 in |

CNC milling surface finishes

Enhance the performance of your part by choosing superior surface finishes that improve the roughness, hardness, chemical resistance, and cosmetic characteristics of your final component.

CNC milling tolerances

We follow ISO 9001 standards for CNC machining.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm | |

CNC milling design guidelines

Please review the suggested and practically achievable measurements for the prevalent characteristics found in CNC machined components.

| Characteristic | Suggested dimensions | Achievable dimensions |

|---|---|---|

| Minimum.feature.dimension | Ø 2.5 mm | Ø 0.50 mm |

| Internal edges | R 8 mm | R 0.25 mm |

| Minimum wall thickness. | 0.8 mm (for metals) 1.5 mm (for plastics) | 0.5 mm (for metals) 1.0 mm (for plastics) |

| Holes. | Diameter: standard drill bit sizes Depth: 4 x diameter. | Diameter: Ø 0.5 Depth: 10 x diameter |

| Threads. | Size: M6 or larger .Length: 3 x diameter. | Size: M2 |

We have high standards for CNC milling

We produce your bespoke components in accordance with rigorous manufacturing guidelines

- Various surface finishes can be utilized to enhance the aesthetic appeal of your components following the machining process.

- Our manufacturing partners conduct on-site inspections of each custom part in accordance with our guidelines.

- Inspection reports and other types of quality documentation are available on request to assure the highest quality and compliance.

Additional materials available for CNC lathe operations

Discover more about the functioning of CNC turning and enhance your understanding of designing superior components for this particular machining technique