Table of Contents

Low Volume Aluminum Extrusion Services

Combine with CNC and Other Methods

Global Delivery in 2-3 Weeks

If you are in need of a specific length for an extrusion profile and require a large volume, it is highly recommended to directly approach an extrusion company. Numerous extrusion companies specialize in high-volume production. However, these companies are generally not interested in handling low-volume projects for aluminum and plastic extrusions, unless you hold VIP status with them. Consequently, obtaining prototype aluminum and plastic extrusions can be quite challenging. At XinYang, we have established reliable partnerships for short run custom aluminum extrusions and short run plastic extrusion services. Our partners diligently oversee our projects, ensuring both quality and timely delivery. Additionally, we conduct routine quality control checks on your project prior to shipment.

We possess a significant number of CNC machines in-house, allowing us to conduct precise post-machining, which sets us apart from conventional extrusion companies.

Customization

We provide tailor-made aluminum extrusion profiles, and we possess the capability to integrate extrusion with additional manufacturing techniques like CNC milling, turning, and bending in order to fabricate the end components.

Low Volume

Many extrusion companies establish excessively high minimum order quantities (MOQs). However, 3ERP stands out by not imposing such restrictions, making us the ideal option for smaller production volumes. Whether you require one-off prototype extrusions or just a few hundred units, we can accommodate your needs without any difficulty.

Fast Delivery

Should you wish to avoid a 30+ day wait for the manufacturing of your extrusion mold and profiles, we are here to assist you. Our team can complete the process in half the time typically required by the industry, or even quicker.

Custom Low Volume Extrusion Services

Plastic Extrusion

Polystyrene, nylon, polypropylene, and polythene are examples of plastic materials known as thermoplastics. When heated and subjected to pressure in a mold, these materials can be molded into various shapes and sections.

Aluminum Extrusion

Aluminum extrusion is the method by which aluminum material is shaped by being pushed through a specifically designed opening in a die. The end result is an elongated piece of aluminum.

What is Aluminum Extrusion?

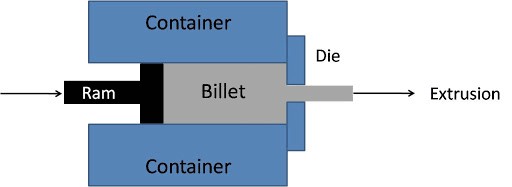

Aluminum extrusion involves the manipulation of aluminum material by directing it to flow through a specifically shaped opening in a die. This process results in the aluminum material emerging from the die as a lengthened piece with a continuous cross-sectional profile, which can be intricate and intricate. To simplify extrusion for those unfamiliar with the concept, one can compare it to the production of pasta shapes or Play-Doh. In both cases, dough is inserted into a chamber, pressure is applied by rotating a crank or handle, and strands of the material are extruded through a small aperture. By altering the attachment for this aperture, the cross-section of the extruded strands can be modified, allowing for the creation of various shapes such as tagliatelle, penne, and more.

Certainly, aluminum billets do not possess the same level of flexibility as pasta dough. Consequently, the aluminum extrusion procedure necessitates a substantial amount of force, often achieved through the utilization of immense hydraulic pressure. Additionally, in certain instances, heat may also be applied during the process.

How Does Aluminum Extrusion Work?

The process of aluminum extrusion can be conducted in two different manners: hot extrusion or cold extrusion. Each method has its own advantages. Hot extrusion enables larger quantities of aluminum to be inserted into the die rapidly and with less pressure, whereas cold extrusion can yield mechanically superior components with a smooth surface finish and enhanced resistance to oxidation.

Prior to hot extrusion of aluminum, it is necessary to cut aluminum billets to the correct size. Subsequently, these billets are heated in an oven to a temperature ranging from 300 °C to 600 °C, ensuring the metal becomes malleable without reaching a liquid state.

When the heated aluminum billets are subjected to hydraulic pressure, a ram is utilized to push them into the die. The die can either have a standard aperture, such as a round or square hole, or it can be customized with a specific profile. A significant amount of pressure, approximately 10,000,000 pounds, is necessary to successfully extrude the heated aluminum through the die.

The extrusions are subsequently cooled on a cooling table, prior to being trimmed to the desired lengths as per the customer’s specifications. Aluminum can also undergo heat treatment for increased hardness.

Common Sheet Metal Applications

- Aerospace

- Construction industry

- Electronics

- Automotive

- Medical Devices

- Automation

- Trains

- Display industry

- Ships

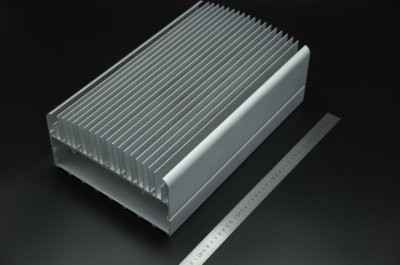

- Heatsink

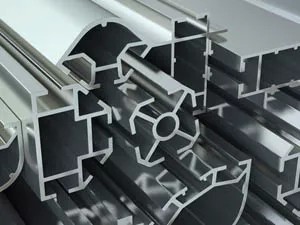

Standard Aluminum Extrusion Profiles

Custom aluminum extrusion profiles have the flexibility to be tailored to any desired 2D cross-sectional shape. Nevertheless, there exist a range of standard aluminum extrusion profiles that are well-suited for numerous projects. These include extruded aluminum bars and extruded aluminum channels, available in diverse forms.

Standard profiles include:

- Circular bar

- Square tube

- T-shape

- F-shape

- Square bar

- L-shape

- C-shape

- Circular tube

- U-shape

- J-shape

Profiles also come in standard sizes and series. These include:

- 2020 aluminum extrusion (20 mm x 20 mm)

- 80/20 aluminum extrusion (T-slot aluminum extrusion)

- 2040 aluminum extrusion (20 mm x 40 mm)

- 3030 aluminum extrusion (30 mm x 30 mm)

Custom Aluminum Extrusion Profiles

If you require a significant amount of standard extruded aluminum profiles, it is advisable to utilize the services of extrusion specialists who specialize in mass manufacturing such profiles, such as extruded aluminum channel or extruded aluminum bar. These companies are well-equipped to meet your needs efficiently and effectively.

Nevertheless, if you require custom aluminum extrusion profiles with a unique shape that deviates from the standard, 3ERP could be a more suitable choice. This is due to our capability to accommodate low-volume extrusion orders, ideal for prototyping and small batch production, enabling you to explore various custom profiles.

Furthermore, apart from fabricating personalized aluminum extrusion profiles through the utilization of custom dies, we possess the capability to integrate extrusion with various manufacturing techniques, such as CNC machining, in order to fabricate customized end products. This approach enables us to expedite the production process and reduce costs, particularly when the majority of the part exhibits a uniform cross-section.

Example operations:

Creating a custom extrusion, then using a CNC mill to add details, holes, or threads.

Creating a round extrusion, then using a CNC lathe to add taper or other features.

Creating a custom extrusion, then adding text or other engraving with a laser cutter.

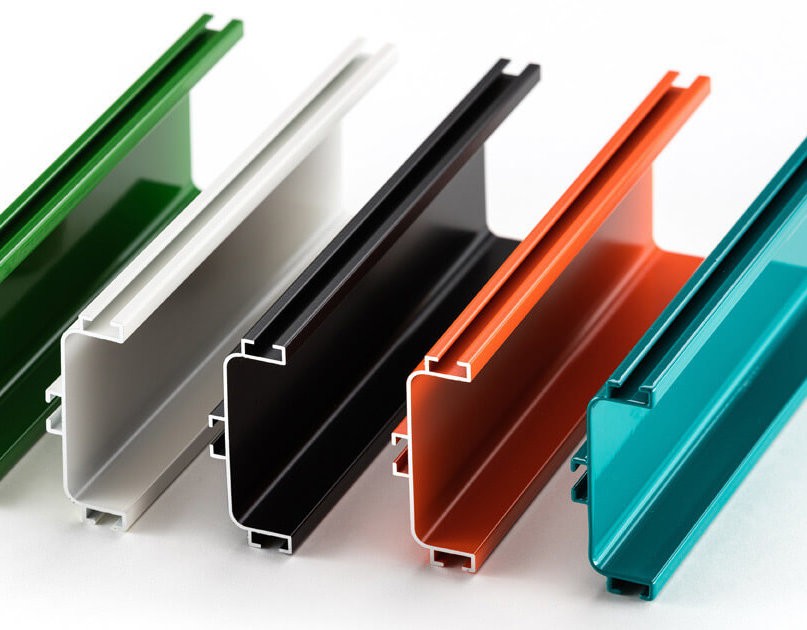

Finishing Options for Aluminum Extrusions

Aluminum extrusion is used to mass produce lots of non-cosmetic parts like tubing and frames, where finishing may not be especially important. However, custom aluminum extrusion is also used to produce high-value products which may benefits from the addition of color, text, logos, and other finishing procedures.

Suitable surface finishing procedures for aluminum extrusion include:

.

- Basic mechanical finishing: Aluminum extrusion is commonly employed for the mass production of various non-cosmetic components such as tubing and frames, where the emphasis on finishing may not be particularly crucial. Nevertheless, custom aluminum extrusion is also utilized to manufacture premium products that can greatly benefit from the incorporation of color, text, logos, and other finishing techniques.

- Anodization: Aluminum extrusions have the capability to undergo anodization in order to acquire a protective coating that is resistant to scratches and oxidation, while also enhancing their aesthetic appeal.

- Painting: Painting an aluminum extrusion can effectively change both the color and surface appearance, whether a matte, gloss, or textured finish is desired.

- Powder coating: Powder coating provides a viable option to anodizing, offering superb chemical resistance and uniformity in color.

- Silk-screen printing: Silk-screen printing offers a cost-effective method for incorporating text and logos onto aluminum extrusions compared to more expensive machine-based finishing techniques.

- Laser engraving: Laser engraving is a valuable technique that can be employed to incorporate intricate details, such as text, onto an extrusion. Moreover, it possesses the advantage of being resistant to wear and tear, ensuring that the engraved information remains intact over an extended period. Consequently, laser engraving proves to be particularly beneficial for crucial aspects like part serial numbers.

Applications of Aluminum Extrusion

Aluminum extrusions are used in heavy industry, aerospace, the food industry, and elsewhere. Common aluminum extrusions include extruded aluminum heatsinks and profiles for tracks, frames, and rails.

- Industrial: Extruded aluminum possesses versatile applications in the manufacturing of industrial equipment such as workbenches and carts, in addition to extruded aluminum frames and framing. Among the commonly used framing systems is the 80/20 extruded aluminum framing, which is based on the T-slot structural framing design.

- Construction: Aluminum extrusion is utilized in various ways in architecture and construction, including the creation of extruded aluminum rails, balustrades, and ladders.

- Electrical: Aluminum possesses electrical conductivity, making it valuable in its extruded state for various lighting components like LED aluminum extrusions, structures for supporting solar panels, and other applications.

- Transport: Extruded aluminum is good for fabricating items like automotive, horse, and boat trailers.

5-Axis CNC Machining FAQ

What are the 5 axes on a CNC machine?

The axes, in terms of CNC machining, determine the number of directions that the cutting tool can move in when producing parts. There are the three-dimensional axes, and the 5-axis machine’s cutting tool can also rotate to approach the part from two directions, which serve as two additional axes.

When does 5-axis machining make sense?

Because of the flexibility offered by 5-axis machining, it should be used to create the most complex shapes and details in parts. The stability of the tool also provides a smoother and more consistent finish.

Can 5-axis provide tight tolerances?

5-axis CNC machining is one of the most advanced manufacturing technologies available, so it can produce some of the tightest tolerances possible, even on complex and detailed parts.

Start Your Project With A Free Quote