Table of Contents

Additive Manufacturing – 3D Printing Services

Plastic & metal printing on demand – Global delivery as fast as 3 days

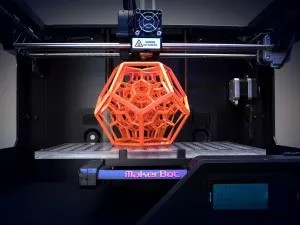

XinYang offers a variety of top-notch 3D printing (additive manufacturing) solutions, such as FDM, SLA, SLS, and SLM. These services cater to the printing of plastics and metals, providing opportunities for both prototyping and production purposes.

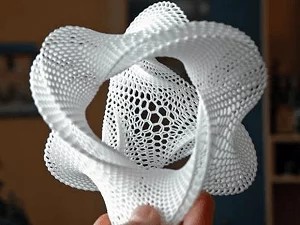

Additive manufacturing is an excellent method for producing unique components or limited quantities, and has the capability to fabricate intricate shapes that are unattainable through conventional production methods.

Advantages of 3D Printing

- Affordability : 3D printing is considered a cost-effective manufacturing process for producing one-off parts or small batches due to its ability to use only the necessary material without requiring tooling.

- geometries: Strong 3D printers fabricate components by building layers one by one with the help of a computer-controlled nozzle. These printers have the capability to produce intricate designs, encompassing intricate interior geometries.

- Efficiency : After being designed with CAD software, a part can be printed within hours, eliminating the need for a time-consuming setup process.

- Adaptability: Due to the fact that 3D printed components do not necessitate tooling, the process of creating a part carries a lower level of risk. In the event that a defect is identified post-printing, it can be rectified digitally without having to invest in costly tooling replacements.

- Environmental factors : While 3D printers need power to function, they typically do not generate any material waste. In contrast, subtractive methods such as machining result in leftover waste material.

What is 3D Printing?

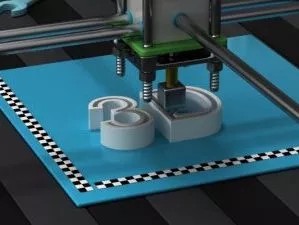

3D printing, otherwise known as additive manufacturing, is a manufacturing process that builds a part layer by layer. A computer sends instructions to the 3D printer, which deposits or hardens material in a preprogrammed pattern, creating layers in succession.

There are several kinds of 3D printer, some of which are used to print plastic parts, others to print parts made from metal or other materials. While these various 3D printing technologies are diverse, they have certain features in common.

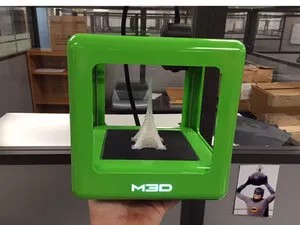

3D printing has revolutionized manufacturing by giving businesses access to a one-step manufacturing technology. 3D printers can be set up in offices and small workspaces, and require minimal training to operate. Moreover, startup costs are incredibly low, since materials are affordable and can be purchased in small quantities.

How to Select 3D Printing Process

If you need assistance in finding which 3D printing process is the right fit for you, you can set up a consultation and planning phase with our team of additive manufacturing experts.

All 3D CAD files you wish to have printed must be provided for the design and reviewed by the production team so they can be optimized and made to meet design requirements. These requirements will differ between FDM, SLA, SLS, and SLM 3D printing, so be sure to optimize your CAD model for the 3D printing process you wish to use.

.

.

3D Print Prototyping Projects

This project was completed for a fashion design company, where they initially requested flexible prototypes made from polymers using expensive SLS technology. However, with our newly developed resin, we can now produce flexible prototypes using SLA technology at just 1/5 of the cost.

The rationale behind this decision was primarily due to the lack of precision in the prototypes provided by other services. Consequently, the company deemed it necessary to seek outsourcing options from Europe. Nevertheless, upon approaching the 3ERP team, they swiftly realized that they had finally stumbled upon a service provider capable of fulfilling their requirements.

Start Your Project With A Free Quote