Inhoudsopgave

Injection Molding ServiInjection Molding Servicesces

XinYang provides low-volume and mass production injection molding services.

Molding quantity started from 100 pieces

Thermoset Silicone

Metals

XinYang – Your reliable partner for high-quality

custom injection molding parts

If you require small quantities of injection molded parts or large quantities of end-use production moldings, our injection molding services are the perfect choice. At XinYang, we specialize in producing top-notch prototype moldings using rapid tooling made from aluminum or soft steel. With turnaround times as short as 7 days, our customers can swiftly verify the manufacturability and functionality of their designs, as well as conduct market testing. Additionally, we provide plastic and metal production moldings to cater to your high-volume production requirements. Our team of skilled specialists is dedicated to offering cost-effective solutions at every stage of the process.

Our Injection Molding

Capabilities

We are always ready for the challenges of all types of injection molding parts, such as tight tolerances, thin wall, small draft angle, undercuts, complex part geometry, non-defect surface finishes, etc.

Plastic Injection Molding Service

Thermoplastic, the most widely used method for custom plastic injection molding, is well-suited for a variety of applications including consumer products, automotive components, and numerous other industries.

Liquid Silicone Rubber Molding Service

Liquid silicone rubber, which is both inert and biocompatible, finds extensive application in the production of molded medical items like fluid management and respiratory devices.

Metal Injection Molding Service

MIM is a cost-effective option for producing small and intricate metal components, particularly in high quantities, while also minimizing material waste compared to CNC machining.

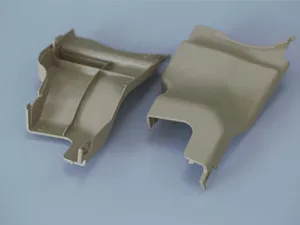

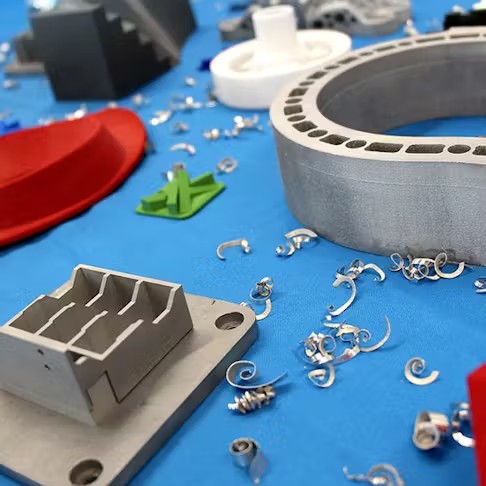

Injection Molding Gallery

To provide you with a comprehensive understanding of our injection molding capabilities, we would like to showcase a selection of our past projects. At 3ERP, we possess the versatility to cater to various requirements for high-quality injection molded parts. Therefore, if you are seeking a reliable mold making and injection molding company for your projects, there is no need to search elsewhere!

Addition Injection Molding Options

Besides basic injection molding services, we also offer two variants of the process – overmolding and insert molding. Both of these can be useful in specific situations.

Overmolding

Overmolding utilizes injection molding to produce a component using multiple materials. This technique involves adding an injection-molded layer of material onto a pre-existing injection-molded piece. Through overmolding, chemically bonded parts are manufactured using a variety of materials.

The overmolding technique is frequently more cost-effective and efficient compared to alternative manufacturing methods that involve the separate creation and assembly of component materials. This process can either construct layered parts from the beginning or apply a durable outer layer to pre-existing plastic parts and tools, resulting in a sturdy exterior. An instance of an overmolded product is toothbrushes, which comprise a solid plastic body with a rubberized grip.

Insert Molding

Overmolding is a process that bears resemblance to the mentioned technique, however, the base material does not have to be plastic and is not required to be manufactured through injection molding. An instance of this is applying a plastic coating onto a pre-made metal component.

Insert molding is commonly utilized to produce various components, including sharp handheld tools like scalpels with a metal blade encased in a plastic handle. Additionally, this method is often employed to manufacture inserts that feature bushings, clips, and fasteners.

Prototyping & Low-Volume Production

The usual practice is to create prototype molds with a single mold cavity using either aluminum or P20 steel. This is done by manually inserting components to eliminate the need for cylinders and lifters. Additionally, utilizing a standard stock mold base helps reduce the overall cost of the mold. This approach proves to be highly effective in obtaining a small number of prototypes made from actual materials for testing purposes. Moreover, it can also be employed to manufacture hundreds or even thousands of bridge production parts within a significantly short timeframe.

Mass Production

It is crucial to minimize the injection molding cost when preparing for mass production of millions of moldings. To achieve this, production injection mold tools are designed with multiple cavities to decrease the cycle time, and they are made from fully hardened tool steel to ensure their longevity. Additionally, the utilization of robots is widespread in order to mitigate labor costs.

Injection Molding Materials,

Surface Finishes and More

Tooling for Molding and Materials for Molding

A diverse array of industrial-grade materials can be utilized for mold tools and moldings, providing ample choices for material selection to accomplish both prototypes and production runs. Tooling materials like aluminum and steel, as well as molding materials in popular plastics such as ABS, PC, PP, PA, or temperature-resistant plastics like PEI, PPS, and more, are available options.

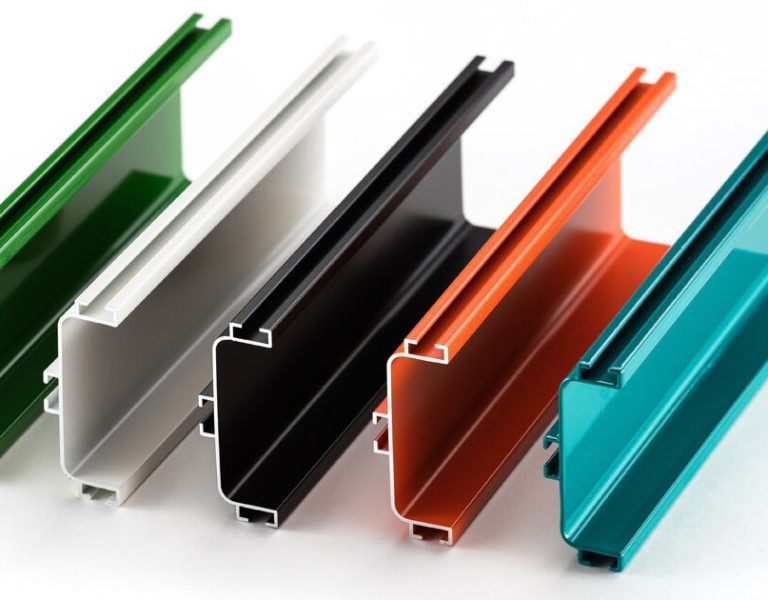

Surface Finishes

XinYang provides a diverse range of premium surface finishes. While we have highlighted a few standard finishing choices, there are additional options available for personalized injection molded components.

Classes of Injection Mold

XinYang provides a diverse range of premium surface finishes. While we have highlightWe strictly follow the five standard categories of SPI mold classifications, ranging from Class 1 to 5, to ensure that both customers and suppliers have aligned expectations.ed a few standard finishing choices, there are additional options available for personalized injection molded components.

Discover More About Injection Molding

XinYang provides a diverse range of premium surface finishes. While we have highlighted a few standard finishing choices, there are additional options available for personalized iHere is additional information regarding injection molding, including an explanation of the process, the steps involved in producing injection molded parts, the four stages of the injection molding process, and the benefits in comparison to alternative manufacturing methods like CNC machining, 3D printing, and laser cutting.njection molded components.