Table of Contents

Aluminum Casting Services

Aluminum One-off prototyping or 1000+ production parts

XinYang has obtained ISO9001-2015 certification and offers top-notch aluminum casting services to manufacturing firms in various industries.

We, as a company, focus on producing top-notch die castings, enabling us to fabricate intricate shapes and designs with exceptional precision.

Perfect for customers in need of high-quality on-demand parts and components in a timely manner, high-quality aluminum casting is an excellent choice for rapid prototyping and small-scale production.

What are the benefits of aluminum die casting?

Aluminum die casting is a highly adaptable manufacturing technique that provides numerous benefits compared to alternative production processes.

Precision: Aluminum die casting enables a superior level of precision and accuracy, which is perfect for manufacturing die-cast parts and components that feature intricate shapes and designs.

Speed: Die casting is a rapid and highly efficient manufacturing technique that enables the production of substantial quantities of aluminum components within a brief timeframe.

Cost-Effectiveness: A cost-efficient manufacturing technique that can help you reduce production expenses for any die-casting endeavor.

Robust Mechanical Properties: Aluminum die castings possess strength and durability, rendering them suitable for a wide range of applications.

If you are in search of a top-notch, productive, and budget-friendly manufacturing method, consider opting for precision die castings provided by XinYang.

Applications of aluminum castings

Modern aluminum castings are highly suitable for a diverse range of applications owing to their exceptional strength, long-lasting nature, and cost-efficiency

Automotive Parts

Aluminum castings are frequently utilized in the manufacturing of automotive components like engine blocks, transmission cases, stators, auto forks, and heat sinks.

Aerospace Parts

Aluminum castings are frequently utilized in the aerospace sector for components like fuselage frames and wing spars due to their exceptional strength-to-weight ratio.

Machine Parts

Aluminum castings have the capability to produce a diverse range of machine components, including gears, pulleys, sprockets, pump covers, and brackets.

Electrical Components

Aluminum cast parts exhibit non-magnetic properties and possess excellent electrical conductivity, rendering them well-suited for use in electrical components like switchgear housings, transformer cases, and junction boxes.

Consumer Products Contexts

Aluminum castings are widely employed in numerous consumer products due to their pleasing visual appeal. Notable instances encompass lawn furniture, ornamental hardware, and architectural embellishments.

Recreational Equipment

Aluminum castings find frequent application in the manufacturing of leisure equipment, including boat hulls, snowmobile frames, and cosmetic components.

Different types of aluminum casting processes

Hot chamber casting

Hot chamber casting, also known as gooseneck casting, is a metal casting process in which molten metal is poured into an externally heated mold cavity.

- Ideal for metals with low melting points, such as zinc, copper, and magnesium.

- Well suited for mass production of small parts with good dimensional accuracy.

- High productivity and relatively low cost.

Cold chamber casting

Cold chamber casting, also known as plunger casting, is a metal casting process in which molten metal is poured into a mold cavity, not heated externally.

- Typically used for metals with high melting points, such as aluminum and copper.

- Cold chamber machines are perfect for producing products/parts with thin walls and complex shapes.

- High accuracy and repeatability

Sand casting

Also known as sand-molded casting, the mold material used in this casting process is sand.

- One of the most widely used casting processes, particularly for ferrous metals (iron, steel).

- The main benefits are low cost and flexibility in terms of design.

- Sand castings can create almost any shape in a wide range of sizes.

Investment casting

Investment casting, also known as lost wax casting, is a process in which a wax model is used to create a mold for molten metal.

- The main benefit of investment casting is its ability to produce parts with very tight tolerances.

- Ideal for low-cost, low-volume production.

Die casting

Die casting uses is a process in which molten metal is injected into a mold under high pressure.

- Suitable for high-volume production of parts with complex geometry.

- The main benefits of die casting are its high accuracy and efficiency.

Permanent mold casting

Permanent mold casting is a process in which a metal mold is used to create parts with complex designs.

- Molds can create intricate designs that are reusable.

- The main benefits are precision and efficiency.

Squeeze casting

Squeeze casting is a process in which molten metal is injected into a mold under high pressure between two dies.

- Typically used for high-volume production of parts with complex shapes.

- The main benefits of squeeze casting are its high accuracy and efficiency.

Aluminum die casting services

XinYang offers a range of aluminum and zinc die-casting options. We can help you choose the best solution for your project needs and requirements.

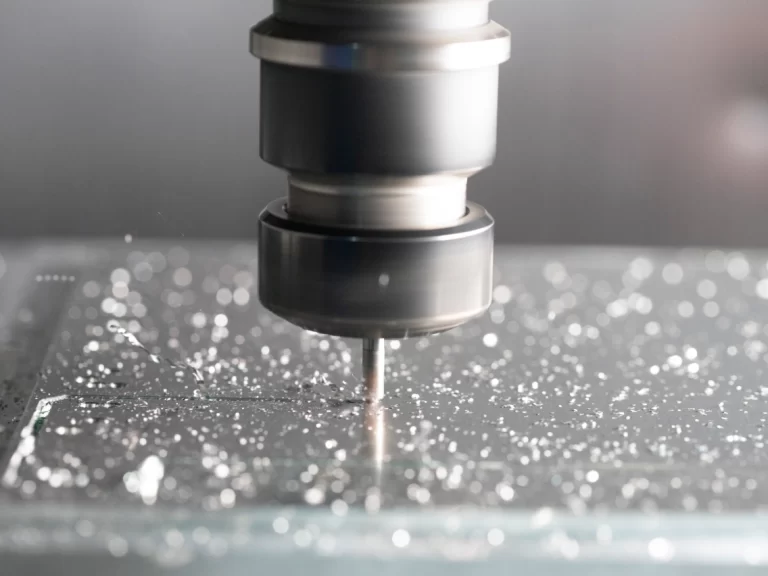

Aluminum die casting involves injecting molten aluminum into a mold at high pressure. This manufacturing process is commonly employed for creating one-off prototypes and producing parts with intricate designs in small quantities.

Our die casting process

Analysis

We evaluate the die casting requirements and specifications for every project, including the necessary aluminum alloys, component size and shape, production volume, and project budget.

Custom die solution

Our team specializes in developing and producing tailor-made aluminum die castings with precision to fulfill the unique needs of each project.

Die Casting

Our advanced die casting facilities produce aluminum shapes/parts by injecting molten aluminum into the die at high pressure, utilizing cutting-edge equipment to ensure top quality.

Finishing

We offer a range of surface finishes for every aluminum casting, such as anodization, powder coating, and plating.

How we guarantee high-quality casting

XinYang acknowledges the significance of top-notch aluminum casting in the triumph of our clients’ endeavors. We strive to surpass expectations by guaranteeing that all our castings not only meet but also surpass the most stringent benchmarks for quality and performance.

We begin by utilizing solely top-grade aluminum alloy for our castings, guaranteeing that our products are robust and long-lasting, capable of enduring the challenges posed by the most rigorous of applications.

Our team of aluminum casting specialists consists of highly skilled and experienced professionals who utilize cutting-edge technology and equipment to ensure the production of top-notch castings.

Advantages of working with 3ERP

- One of the leading aluminum casting companies: ISO9001-2015 certified

- Specialists in rapid die-cast prototypes & small scale production

- Experienced and knowledgeable engineers

- Our team can help you choose the best aluminum casting process for your needs

- State-of-the-art casting equipment to produce high-quality parts

- We offer competitive prices and quick turnaround times

Learn more about our aluminum casting services. Contact us today. We will be happy to answer any questions and provide a quote.

Start Your Project With A Free Quote