Rapid Prototyping Services

3D Printing | CNC Machining | Urethane Casting

Sheet Metal | Rapid Injection Molding | Prototype Extrusions

100+ Materials and various surface finishes

Services

If you are in need of a professional prototyping service to bring your ideas to life and assist with product development, then you have come to the right place. XinYang is dedicated to providing exceptional quality, fast turnaround, and cost-effective rapid prototyping services to customers worldwide. With state-of-the-art prototyping and production manufacturing technology, advanced industrial-grade equipment, and a team of skilled engineers, XinYang can transform your design into a market-ready product within a matter of days. We are thrilled to begin collaborating with you! If you have completed the prototyping phase and are ready to progress to production, we invite you to explore our low volume manufacturing service. Here are the primary rapid prototyping processes we offer:

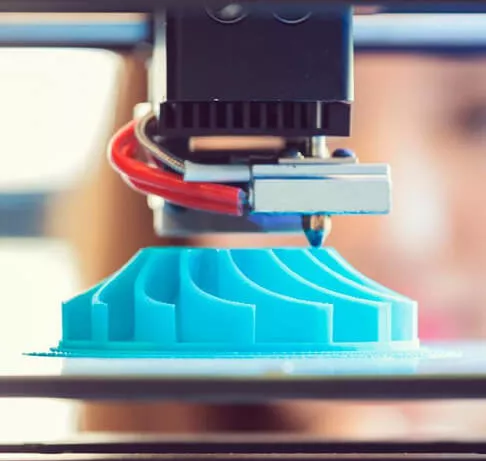

Rapid 3D printing

XinYang offers a variety of 3D printing technologies as part of their rapid prototyping service for additive manufacturing:

Our rapid prototyping services for 3D printing cater to a wide range of materials, including plastics and metals, offering a variety of material and finishing choices. In addition to prototyping, these additive manufacturing technologies can occasionally be utilized for production purposes.

Due to the absence of tooling, the prototyping process for 3D printed parts is quick while maintaining high build quality. Additional benefits consist of design flexibility and cost-effectiveness, particularly for small production runs.

3D printing is often preferred for concept models, but precision technologies SLM can also work for functional prototypes and even production parts.

FDM — Low-cost plastic parts prototyping

SLA — Plastic parts prototyping with exceptional surface finish

SLS — Strong prototyping parts in nylon or nylon glass

SLM — Metal parts prototyping in steel or titanium

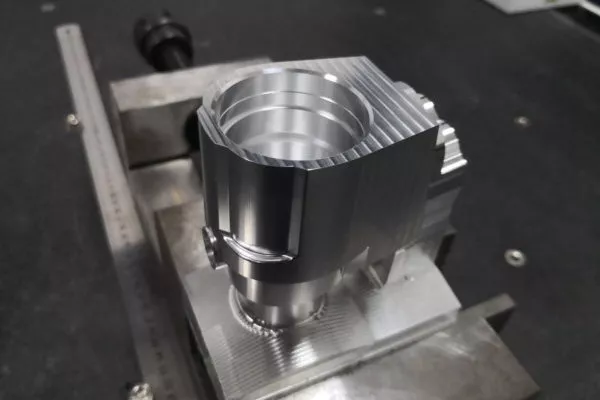

Rapid CNC machining

XinYang runs an extensive array of CNC machining centers, mills, and lathes (specifically for CNC turning), which facilitate quick prototyping of CNC machined components crafted from either plastic or metal. Our services encompass a diverse selection of materials and finishing choices, as well as the opportunity to integrate CNC machining with various other rapid prototyping techniques.

CNC machining stands out as a top-tier rapid prototyping technology due to its high precision. While emphasizing quick turnaround times over extremely tight tolerances, the quality of rapid CNC machining remains exceptional.

Low volumes result in quick turnarounds, with CNC prototyping yielding parts that closely resemble production quality. Although more expensive than 3D printing, the surface finish and strength of the parts are frequently superior.

CNC Milling — Milled prototype & production parts in plastic and metal

CNC Turning — All types of round components

CNC Grinding — Tight tolerance and good surface

CNC EDM — For deep pocket & sharp conners.

Our 3D printing rapid prototyping services cover a diverse selection of materials, encompassing both plastics and metals, providing an array of material and finishing options. Apart from prototyping, these additive manufacturing technologies can also be occasionally employed for production needs.

The rapid prototyping of 3D printed parts guarantees high build quality due to the absence of tooling. Additionally, it provides benefits like design flexibility and cost-effectiveness, particularly for small production runs.

3D printing is often selected for creating concept models, whereas precision techniques such as SLM can be employed for functional prototypes and even manufacturing parts.

Rigid Plastics — Such as ABS, PC, PA simulate prototype parts

Soft Rubber — Rubber like prototypes from Shore A 30 to 90 degrees.

Wax — Patterns for low-vlume investment casting

Rapid tooling

Rapid tooling (bridge tooling or prototype tooling) refers to the rapid CNC machining of metal tooling for injection molding. It is therefore the first step toward rapid injection molding.

Prototyping tooling for molding is recommended for customers needing 100 to 2,000 units of their injection molded parts. If the quantity exceeds this range, production-level steel tooling might be a more suitable option.

Rapid tooling offers several benefits, such as quick turnaround times and the capability to conduct prototyping and testing of injection molded components that would typically require months to manufacture. Additionally, rapid tooling proves to be considerably more cost-effective compared to mass production tooling.

Despite the higher cost compared to 3D printing, rapid tooling and rapid injection molding offer plastic parts that closely resemble production quality, making them suitable for functional testing purposes.

Plastic Injection Mold

Die Casting Mold

Extrusion Mold

Rapid sheet metal prototyping is a set of rapid prototyping services for the production of sheet metal parts. This includes various forming, cutting, and assembly processes for manipulating the sheet metal stock in different ways.

Rapid sheet metal prototyping is generally used for flat parts like brackets and enclosures, and it can accommodate a range of sizes, including very large metal parts. Setup times can be longer than comparable processes, but sheet metal is highly cost-effective when making large and relatively simple parts.

An advantage of rapid sheet metal prototyping is that the solid sheet metal feedstock can later be CNC machined for additional features.

Extrusion Mold

Stamping

Welding

Rapid metal casting

It is advisable for customers requiring 100 to 2,000 units of their injection molded parts to utilize prototyping tooling for molding. For quantities beyond this range, production-level steel tooling may be a more appropriate choice.

Rapid tooling provides numerous advantages, including fast turnaround times and the ability to carry out prototyping and testing of injection molded components that would normally take months to produce. Moreover, rapid tooling is significantly more cost-efficient than mass production tooling.

Despite the elevated price in comparison to 3D printing, rapid tooling and rapid injection molding provide plastic components that closely resemble the quality of production, rendering them appropriate for functional testing objectives.

Pressure Die Casting

Investment Casting

Gravity Casting

Why opt for our rapid prototyping services?

Exceptional. Productive. Cost-effective.

XinYang’s rapid prototyping services are defined by these three principles. By collaborating closely, we can transform your product vision into a tangible reality within a short span of time, all at a reasonable cost.

No MOQ

We can accommodate one-time prototypes and small-volume parts with flexibility. Regardless of the quantity you require, we are capable of managing your order.

Competitive Pricing

We have developed a highly effective rapid prototyping system that enables us to provide cost-effective prices that are comparable to any other offer.

Rapid Turnaround

We have the capability to complete your rapid prototyping projects within a matter of days.

Experienced Engineers

Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

Tight Tolerances

We cater to the aerospace and medical sectors, providing precise parts with stringent tolerances.

Wide Range of Materials

We cater to a diverse clientele and have the capability to provide an array of rapid prototype materials and finishes.

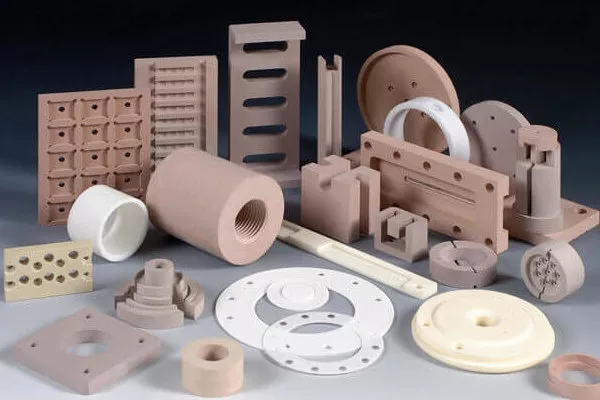

Rapid Prototyping in Multiple Materials

It is crucial to locate a dependable rapid prototyping company that can manage a variety of materials when considering outsourcing your rapid prototypes. XinYang presents an excellent choice in this aspect. We possess the capability to manufacture prototype parts using plastics, metals, and ceramics, ensuring that your entire rapid prototyping project remains centralized.

Plastics

A plastic prototype created through 3D printing, urethane casting, or CNC machining is the prevailing and cost-effective method to assess the visual appeal and functionality of your design.

Metals

Metal prototypes and parts are typically manufactured through various methods such as CNC machining, sheet metal fabrication, metal 3D printing, or the casting process. The commonly used metals for these applications encompass aluminum, magnesium, steel, brass, copper, and more.

Ceramics

Ceramics possess exceptional rigidity, insulation, and temperature resistance, making them highly advantageous for rapid prototyping. These qualities have made ceramics widely sought after in various industries. Our range of offerings includes Alumina, ZrO2, AIN, Si3N4, and SiC, catering to diverse prototyping needs.

Prototypes and Parts Delivered Fast with 4 Simple Steps

Upload a CAD File

Begin by entering some details and uploading a 3D CAD file.

Quote & Design Analysis

You will be provided with a quotation shortly, and in case it is required, we will forward the design for manufacturability (DFM) analysis to you.

Order Confirmation

After reviewing the quotation and confirming your order, the manufacturing process will commence. Additionally, we provide various finishing options for your convenience.

Parts Are Shipped

Your prototypes or custom-made parts will undergo thorough inspection before being promptly delivered to your doorstep.