Various Kind of Options Available

Production Level Surface Finishing

For Both Metal and Plastic Parts

Surface finishing encompasses various methods employed to modify the surface of a fabricated item in order to achieve a unique or desired visual and tactile experience. Diverse techniques are utilized to enhance the aesthetics, adhesion, solderability, corrosion resistance, hardness, conductivity, and numerous other attributes of industrial components.

XinYang provides a top-notch surface finishing service for all components and parts, irrespective of the machining method employed during their production. Our team comprises proficient experts who specialize in handling finishing assignments, ensuring that the work conducted on your products is of unparalleled quality. If you seek a flawless finish for your prototypes and other manufactured components, please reach out to our customer services team for a prompt and precise quotation.

What you can get from us?

Sanding and polishing are frequently used finishes for prototyping. Sanding is a fundamental step in eliminating cutting or printing marks to achieve a smooth surface. This prepares the prototype for additional finishes like sandblasting, painting, or chroming.

Sanding and polishing are frequently used techniques for finishing prototypes. Sanding is a fundamental process that is employed to eliminate cutting or printing marks, resulting in a smooth surface. This prepares the prototype for additional finishes such as sandblasting, painting, or chroming.

Painting offers a highly versatile method to achieve a distinct visual texture.

We can achieve:

- Matt

- Satin

- High Gloss

- Texture (spanght & Heavy)

- Soft Touch ( Rubber spanke)

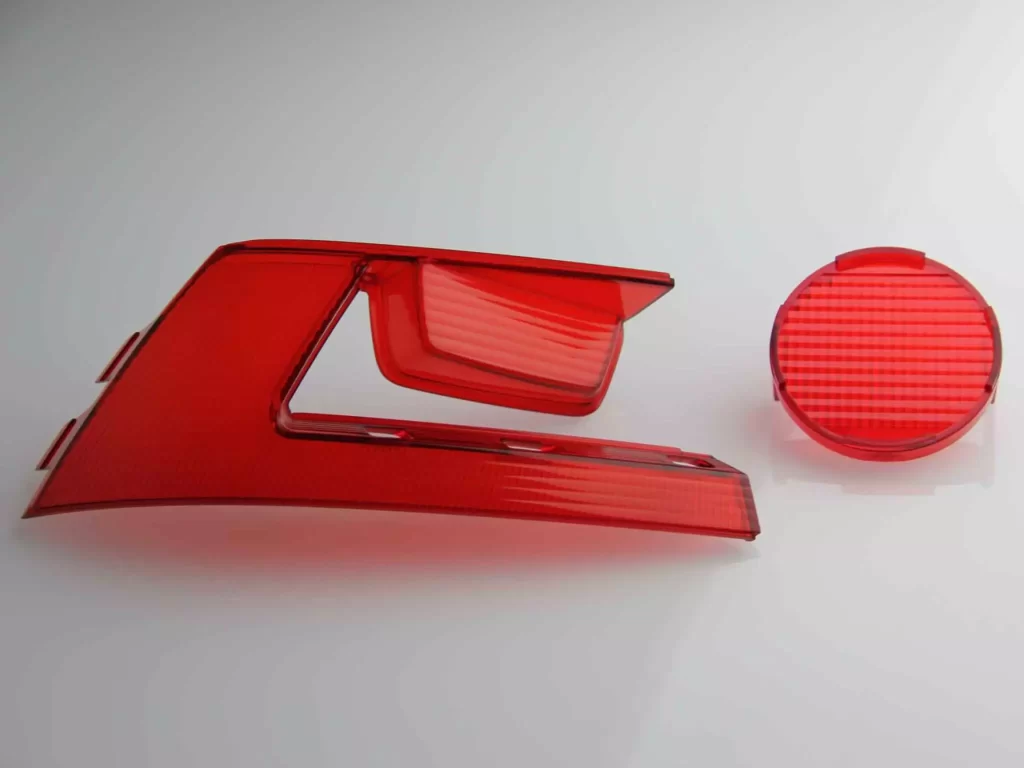

Tinting serves as an alternative to painting when it comes to coloring plastic prototypes. It proves to be a viable choice for components like turn signals and tail lamps.

Material suit for tinted:

- ABS

- PMMA

- PC

- PS

Anodized is the preferred method for creating a high-quality surface for electronic devices, with Apple utilizing this technique for the majority of their products.

We are offering:

- Anodized Type 1

- Anodized Type 2

- Anodized Type 3

- Chemical Film/Alodine

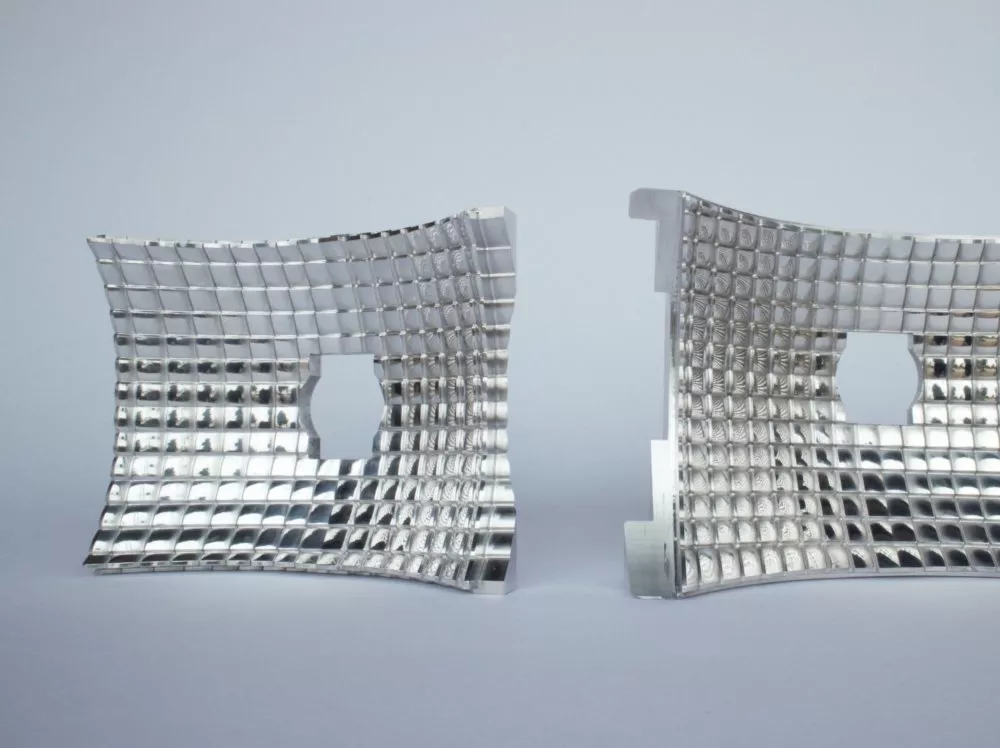

This particular finish not only serves as a protective layer but also enhances the overall appearance.

We can achieve:

- Chromed

- Metalspanzing

- Chrome Sputtering

- Color Plating

- Zinc Plating

- Tinning

There exist multiple methods for designing a logo, symbol, and text on your prototypes or production components.

We can offer:

- Silk-Screen

- Pad Printing

- Rub on

- Laser Engraving

We are also providing:

- Powder Coat

- Eletrophoresis

- Sandblasted & Bead blasted

- Heat treatment

- Blacking

- Water Transfer