Metal Parts Fabrication Guide

Everything You Need to Know

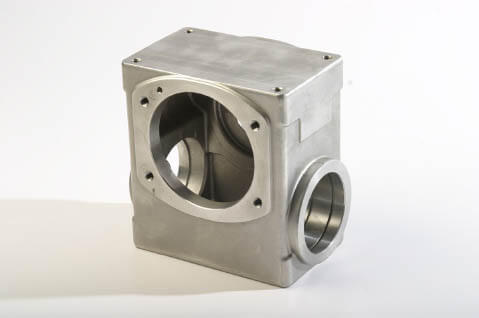

CASTING

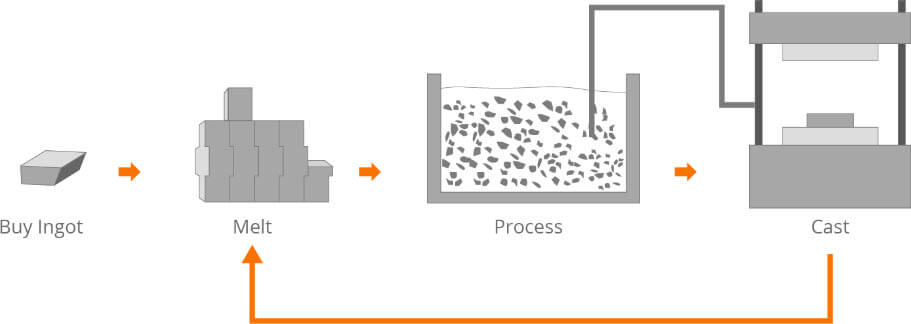

The process of creating empty spaces or components by pouring molten metal into a molding cavity that matches the shape and size of the desired part, and allowing it to cool and solidify, is commonly referred to as the formation or casting of liquid metal.

Processing flow: Liquid metal –> mold filling –> solidification & contraction –> casting

Processing characteristics:

- Capable of manufacturing components with intricate designs, particularly within enclosed spaces.

- The adaptability is robust, with a wide range of alloy categories and unrestricted casting sizes.

- Extensive range of materials, leftover pieces that are capable of being melted again, and affordable equipment costs.

- The prevalence of waste material, subpar surface finish, and unfavorable working conditions are prevalent issues in this context.

Casting category:

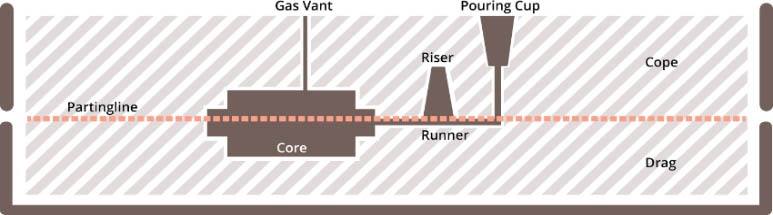

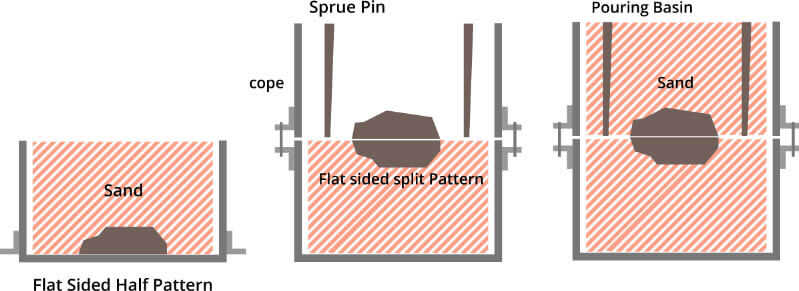

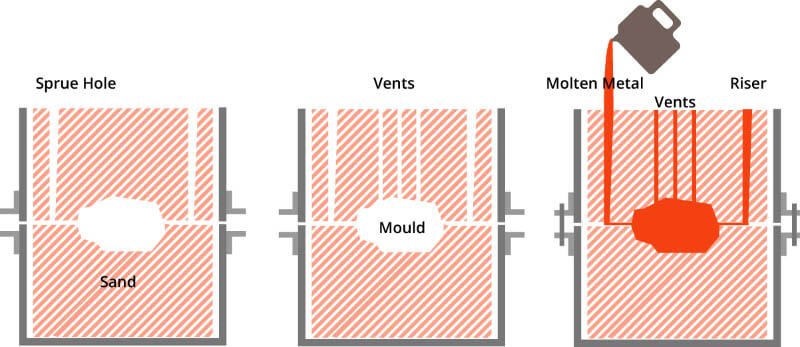

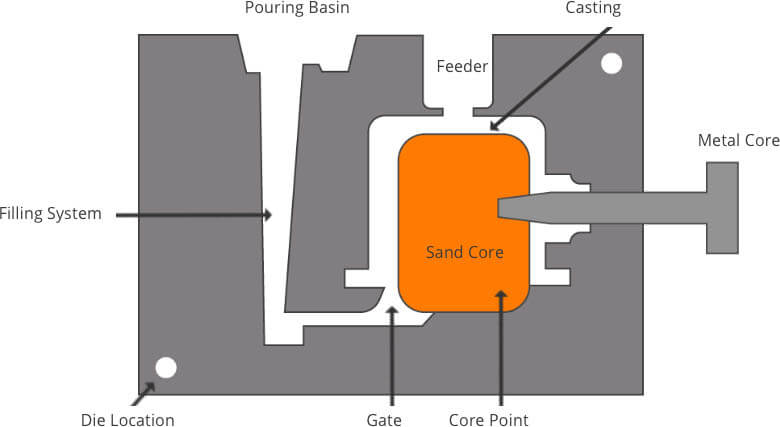

Sand casting

Sand casting is a technique used to produce castings in sand molds, allowing for the creation of steel, iron, and various nonferrous alloy castings.

Processing flow:

Technical features

- Ideal for creating intricate shapes, particularly within cavities.

- Extensive versatility at an affordable price.

- Sand casting is the sole forming process available for producing parts or blanks from materials that have limited plasticity, like cast iron.

Application: Components such as the engine cylinder block, cylinder head, crankshaft, and other castings are commonly utilized in the manufacturing of automobiles.

Investment Casting

A commonly known casting method, referred to as “dewaxing casting,” utilizes a fusible material to create a pattern. Multiple layers of refractory material are then applied to form a shaping shell. The pattern is subsequently melted, leaving behind an integrated casting mold. This mold is then subjected to high temperatures and can be utilized for casting through sand filling.

Processing flow:

Processing advantages

- Exceptional accuracy in dimensions and shape.

- Elevated surface roughness.

- Have the capability to manufacture castings with intricate external shapes regardless of the cast alloy used.

Processing disadvantages

1. Complex processes and increased expenses.

Small parts with intricate shapes and high accuracy can be produced using these applications, especially those that are impossible to manufacture through other methods, like turbo engine blades.

Die Casting

The casting is formed when high-speed, high-pressure metal liquid is injected into a precise metallic mold cavity. The metal liquid then cools and solidifies within the mold, resulting in the formation of the casting.

Processing flow:

Processing advantages

- Exceptional accuracy in dimensions and shape.

- The product exhibits high quality, consistent sizing, and excellent interchangeability.

- Enhanced efficiency and increased longevity of the die.

- Ideal for mass production, offers significant cost advantages.

Processing disadvantages

- The castings typically exhibit small air voids and shrinkage porosity.

- Die casting is known for its limited malleability and is unsuitable for environments that experience high impact loads and shocks.

- The die casting of high melting point alloy is limited by the shorter service life of the die, thus hindering the growth of die-casting production.

Die casting applications were first utilized in the automobile and instrument industries before expanding to various other sectors including agricultural machinery, machine tools, electronics, national defense, computers, medical devices, timepieces, cameras, and everyday hardware.

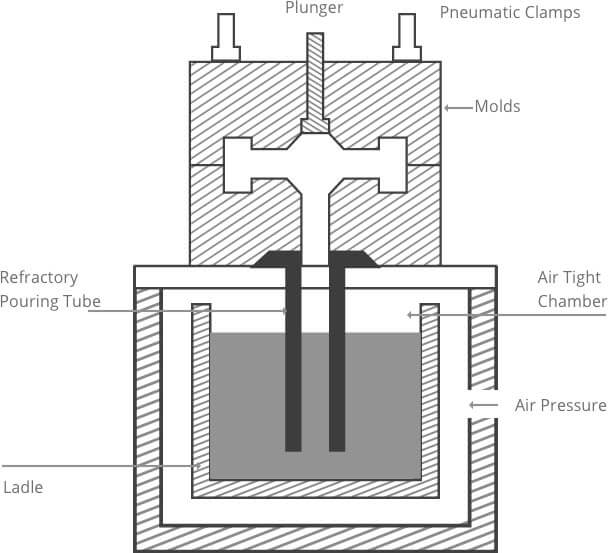

Low Pressure Casting

Casting is produced by crystallization under pressure when liquid metal is poured into a die mold at a relatively low pressure (0.02~0.06MPa).

Processing flow:

Technical features

- The casting process allows for the adjustment of pressure and speed, making it suitable for a wide range of casting molds including metal and sand molds. It can be utilized to cast different alloys and create castings of varying sizes.

- By utilizing the bottom filling method, the metal liquid is smoothly filled without splashing, preventing the entry of air and minimizing flushing to the walls and cores. This ultimately enhances the accuracy of the castings.

- The solidification process occurs under pressure, resulting in a compact structure with a distinct profile, sleek surface, and excellent mechanical characteristics. This is particularly advantageous for producing thin-wall castings.

- The removal of the feeding head has resulted in an increase in metal utilization to 90-98%.

- Low workforce requirements, improved labor conditions, uncomplicated machinery, and the ease of attaining mechanization and automation.

Application It is mainly focused on traditional products (cylinder head, hub and cylinder rack).

Centrifugal Casting

Pouring molten metal into a spinning casting mold to use centrifugal force for filling the mold and shaping the metal into desired forms.

Processing flow:

Processing advantages

- The consumption of metal in both the pouring system and the feeding-head system is minimal, leading to enhanced productivity in the overall process.

- The omission of the mold core in the production of hollow castings allows for a significant enhancement in the metal-filling capacity, particularly in the manufacturing process of elongated tubular castings.

- The casting produced exhibits high density and excellent mechanical properties, with minimal porosity and inclusions.

- Composite metal castings can be effectively utilized in the production of sleeves or bushings.

Processing disadvantages

- The production of special-shaped castings is somewhat restricted.

- The casting exhibits an imprecise bore diameter, a rough internal surface, subpar quality, and a larger margin for machining.

- Gravity segregation can be effortlessly achieved during the casting process.

Centrifugal casting has been historically utilized for the production of cast tubes. This method is employed in the manufacturing of steel, iron, and nonferrous carbon alloy castings that are essential in various industries including metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automotive, among others. It is predominantly known for producing castings like centrifugal cast tubes, cylinder liners, and shaft sleeves that are utilized in internal combustion engines.

Gravity die casting

A technique for creating castings involves the process of pouring molten metal into a metallic mold and allowing it to solidify through the force of gravity within the mold.

Processing flow:

Processing advantages

- Metal molds possess superior heat conductivity and capacity, expedited cooling capabilities, a compact casting structure, and exhibit a mechanical property that is approximately 15% greater than that of sand casting.

- Achieve a casting with enhanced precision in size and reduced surface roughness, along with excellent quality consistency.

- The limited use of sand core contributes to environmental improvement by reducing dust and harmful gases, as well as lowering labor intensity.

Processing disadvantages

- It is necessary to take steps to remove air from the mold cavity and gases from the sand core due to the airtight nature of the metallic mold.

- During the solidification process of casting, the non-flexible metallic mold often develops cracks.

- Metal molds undergo a lengthier production process and incur higher expenses. As a result, more favorable financial outcomes are only evident in mass production.

The metallic mold application is suitable for mass producing nonferrous alloy castings, including aluminum alloy and magnesium alloy components with intricate designs, as well as steel and iron castings or ingots.

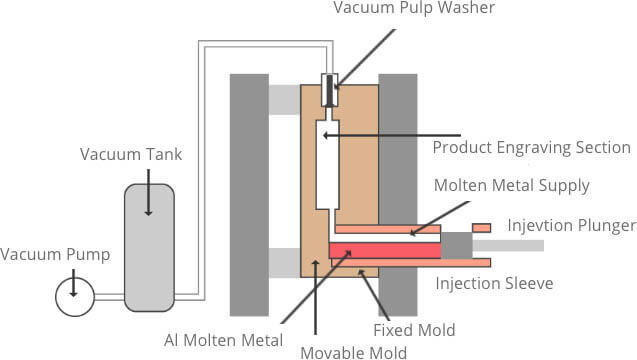

Vacuum Die Casting

A sophisticated die casting technique is employed to enhance the mechanical characteristics and surface integrity of castings by eliminating gas from the mold cavity or significantly reducing the porosity or dissolved gas within the casting.

Processing flow:

Processing advantages

- To enhance the mechanical properties and surface quality of the casting, as well as optimize the coating performance, it is imperative to minimize or diminish the presence of porosity within the casting.

- It is feasible to produce larger castings using a smaller machine by reducing the counter pressure in the mold cavity and utilizing an alloy with lower specific pressure and inferior casting performance.

- It is feasible to produce thinner castings with enhanced filling condition.

Processing disadvantages

- It is feasible to produce thinner castings with enhanced filling condition.

- Improper control of vacuum die casting may lead to insignificant results.

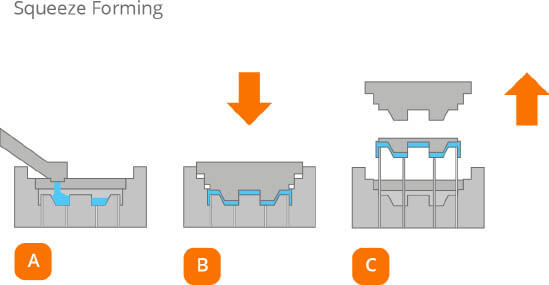

Squeezing die casting

The process of extracting the part or blank directly from liquid or semi-solid metal that solidifies or flows to shape under intense pressure is a metal-forming method that shows promise for use because of its efficient liquid metal utilization, straightforward process, and consistent quality.

Processing flow:

Direct squeezing die casting

Apply spray coating, pour alloy, close mold, pressurize, maintain pressure, release pressure, open mold, remove blank, reset.

Indirect squeeze die casting involves a series of steps: applying a coating spray, closing the mold, feeding the material, filling the mold, applying pressure, maintaining pressure, releasing pressure, opening the mold, removing the blank, and resetting the process.

Technical features

- Internal air pockets, gaps, and shrinkage porosity can be eradicated.

- Achieving a smooth surface finish and precise dimensions.

- It is possible to avoid cracks resulting from the casting process.

- Mechanization and automation can be easily accomplished.

Application: It has the capability to generate a wide range of alloys, including aluminum alloy, zinc alloy, copper alloy, and nodular cast iron.

Lost foam casting

Lost foam casting, also referred to as the full mold process, is a cutting-edge casting technique. It involves the utilization of wax or foam models that are shaped and sized similarly to the desired casting. These models are bonded together, coated with a refractory material, and then dried using heat. Subsequently, they are buried in dry quartz sand and compacted through vibration. The next step involves pouring liquid metal under negative pressure, which causes the models to gasify. As a result, the liquid metal fills the void left by the models. Finally, the metal cools and solidifies, resulting in the formation of the desired casting.

Processing flow:

Pre-foaming -> Foam molding -> dipping in paint arrow-right drying -> shaping -> pouring -> shakeout -> clearing

Technical features

- The processing time is reduced due to the absence of sand core, resulting in high casting precision.

- The design offers a high level of flexibility and freedom due to the integration of the mold surface.

- Production that is free from any form of contamination is essential for maintaining cleanliness and ensuring the quality of the final product.

- Decrease in investment and production expenses.

Application It is suitable for production of precise castings with complicated structure, in various sizes, without limitation to alloy species and batches of production, such as gray pig iron engine housing and high manganese steel elbow.

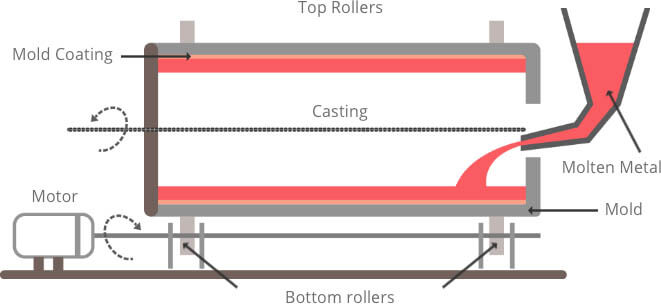

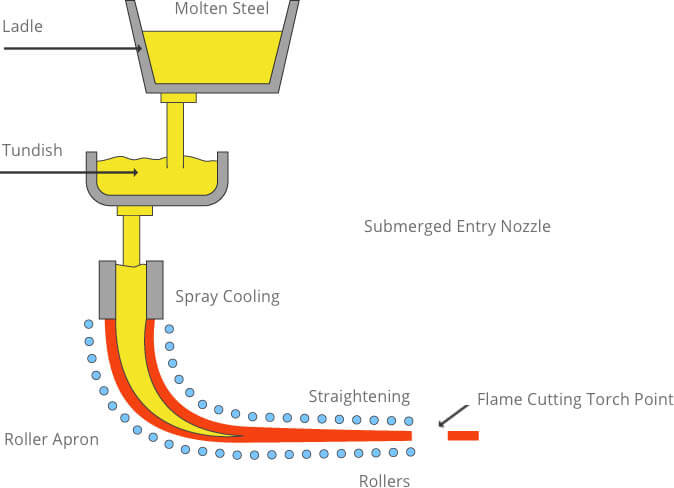

Continual Casting

Continuous Casting is a sophisticated casting technique where molten metal is poured continuously into a specialized metallic mold known as a crystallizer. The solidified casting is continuously extracted from the opposite end of the crystallizer, allowing for the production of castings of varying lengths.

Processing flow:

Technical features

- Due to the rapid cooling of metal, the casting exhibits dense crystallization, a uniform texture, and excellent mechanical properties.

- Increased productivity and enhanced efficiency result in reduced metal usage and improved output.

- The labor intensity has been significantly reduced due to the simplified procedure and exemption of shaping and other procedures. Additionally, there has been a considerable reduction in the required production area.

- The continuous process of casting production facilitates the implementation of mechanization and automation, leading to enhanced productivity.

The continuous casting process is suitable for casting steel, iron, copper alloy, aluminum alloy, and magnesium alloy into elongated shapes like ingots, plate blanks, rod blanks, and pipes with uniform cross-sectional form.

FORMING

Plastic forming is a manufacturing technique that utilizes the plasticity of materials to produce components by applying external force through tools and molds, thereby minimizing or eliminating the need for cutting. This process encompasses several methods, including forging, rolling, extruding, drawing, and punching.

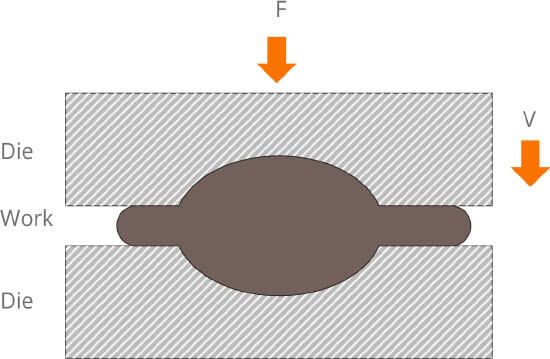

Forging

This technique involves utilizing a forging machine to apply pressure on a metal blank, resulting in plastic deformation to produce a casting with specific mechanical properties, shape, and dimensions.

There are four main types of forging processes based on the forming mechanism: free forging, die forging, roll forging, and special forging.

According to the forming mechanism, forging can be categorized into four types: free forging, die forging, grinding ring, and special forging.

Mold forging involves the use of a mold on either a mold hammer or a hot die forging press to shape the material.

Grinding ring refers to the utilization of specialized ring rolls equipment for the production of ring components with varying diameters. This technique can also be employed in the manufacturing process of automobile hub, train wheel hub, and other ring components.

Special forging encompasses various forging methods such as rolling forging, cross wedge rolling, radial forging, liquid forging, and others. These techniques are specifically designed to manufacture components with unique and intricate shapes.

Processing flow

Blank heating -> rolling to prepare blank -> die forging -> cutting the edges -> punching -> rectifying -> intermediate inspection -> heat treatment of forged piece -> clearing -> rectifying -> inspection

Special forging

- The fabricated component exhibits superior resistance to impact when contrasted with the cast component. Its plasticity, toughness, and other mechanical characteristics surpass those of a cast or even a rolled component.

- With fewer resources and a shorter production time..

- Increased efficiency..

- Free forging offers greater flexibility and is well-suited for the production of single pieces in small quantities.

Application includes rolls and herringbone gears in heavy mills, rotors, blades, and retaining rings in steam turbine generator units, working cylinders and columns in large hydraulic presses, locomotive axles, and crankshafts and connecting rods in automobiles or tractors.

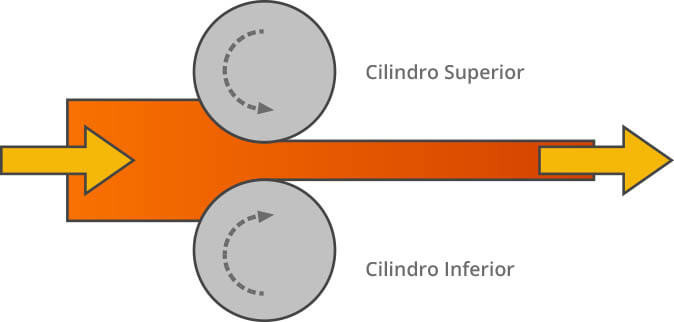

Rolling

A technique of processing that compels a metal blank to traverse through a set of rotating rolls (available in different forms) in order to diminish the material’s cross-section and elongate it through the rolls’ compression.

The rolling category comprises axial rolling, cross rolling, and skew rolling, which are determined by the movement of the rolled piece.

Axial rolling: Metal undergoes plastic deformation as it passes between two rolls rotating in opposite directions.

Cross rolling: The rolled piece, following deformation, travels parallel to the axis of the rolls.

Skew rolling: The rolling piece moves in a helical manner and creates an angle that is not specific with the axis of the roll.

The application is primarily utilized for metallic sections, plates, or tubes, as well as certain non-metal products like plastics and glass.

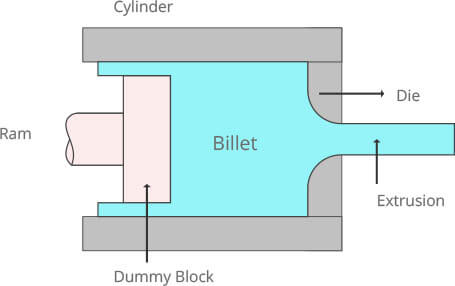

Extruding

The extrusion forming process involves subjecting a blank to non-uniform stress in three directions as it is extruded through a slot or gap to decrease its section and elongate its length, resulting in the desired product.

Processing flow

Preparation before extruding -> cast rod heating -> extruding -> stretching, twisting and straightening -> sawing (sizing) -> sampling for inspection -> man-hour efficiency -> packing and warehousing piece -> clearing -> rectifying -> inspection

Processing advantages

- The production scope has been expanded, encompassing a broader range of products with various specifications and types.

- Small batch production benefits from high production flexibility.

- The product size is characterized by its high precision, ensuring excellent surface quality.

- Decreased investment in machinery; smaller workshop space requirements; simplified implementation of automated manufacturing.

Processing disadvantages

- Increased waste of geometric remnants.

- Irregular metal distribution.

- Decreased extrusion velocity prolongs secondary duration.

- The greater the damage inflicted upon the tools, the higher the associated expenses.

The production scope of applicability primarily focuses on the manufacturing of components that possess elongated dimensions, profound cavities, delicate thickness, or distinctive profiles.

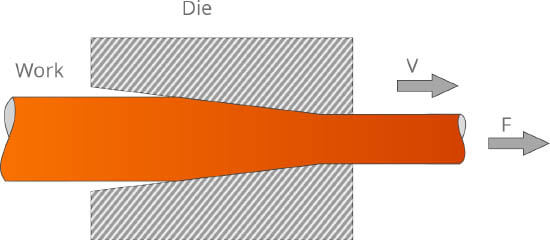

Drawing

A technique of metal processing employs the malleability of metal to obtain products of suitable shapes and sizes by exerting force on one end of the metal and drawing the metal blank through a die hole that has a smaller cross-sectional area than the metal blank.

Processing advantages

- The size is precise and the surface is exceptionally smooth.

- Basic tools and machinery.

- Consistently manufacture lengthy items with narrow dimensions rapidly.

Processing disadvantages

- Pass deformation and total deformation between two annealing are both restricted to a certain extent.

- Restricted in terms of length.

The range of production to which this applies includes the primary process of shaping metal tubes, bars, sectional materials, and wire rods.

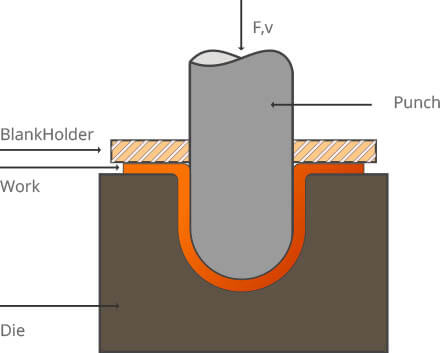

Punching

Punching: Stamping is a manufacturing technique that utilizes a press and mold to exert external force on a plate, strip, tube, or sectional material. This method aims to achieve plastic deformation or separation, ultimately resulting in the desired shape or size of a work-piece.

Technical features

- Version 1: Achieve the capability to obtain products that are lightweight yet possess high rigidity.

- Good productivity enables the production of batch products at a reduced expense.

- Ensure the acquisition of products of consistent quality.

- The material is utilized efficiently with excellent shearing and recovering capabilities.

The production scope of steels is vast and encompasses various applications. Approximately 60-70% of the steels produced globally are in the form of plates, which are extensively used in stamping processes. These stamped plates find their utility in numerous components such as car bodies, chassis, fuel tanks, radiators, and even steam pockets in boilers. Additionally, they are utilized in the manufacturing of container housings, motors, iron cores, and silicon steel sheets for electrical appliances. Stamping techniques are also prevalent in instrument and apparatus production, home appliances, bicycles, office equipment, and everyday utensils.

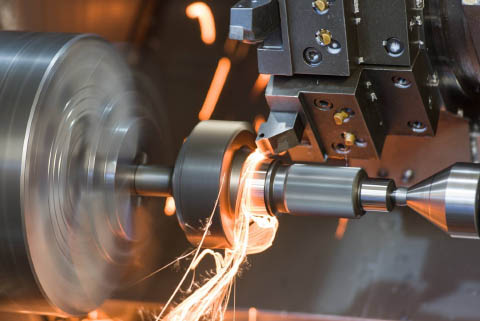

MACHINING

Machining

Machining involves a subtractive manufacturing method where a knife is utilized to remove excess metal from a blank, ensuring precise size accuracy, shape, mutual positioning precision, surface quality, and other technical requirements specified in the drawings.

Suppliers of machining equipment include Mikron and Bumotec from Switzerland, DMG and Hermle from Germany, Mori Seiki, Okuma, Mazak, and Makino from Japan, MAG and Hardinge Bridgeport from the United States, Italian Fidia, Spanish Danobat, Hardinge, and Haas from the United States, Doosan, Hyundai, and Samsung from South Korea, Yeongchin, Tong-Tai, and Dick Lyons from Taiwan, BYJC, BMEIMT, TONMAC, Shenyang, Shinri, Neway, Rifa, Haitian, and Dajin.

WELDING

Welding

Welding, also referred to as fusion, is a manufacturing process that involves joining metal or plastic materials through the application of heat, high temperatures, or high pressure.

POWDER METALLURGY

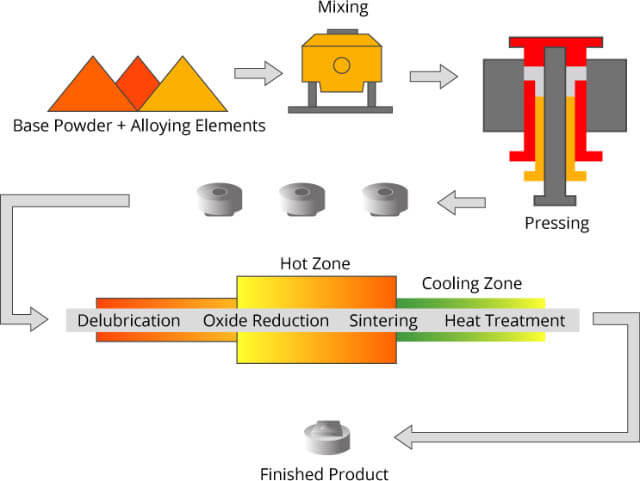

Powder Metallurgy

A manufacturing method utilized to produce metallic materials, composite materials, and a variety of products using metal or metal powder (or a combination of metal powder and nonmetal powder) as the primary material through shaping and sintering. Joining: Joining, also referred to as fusion, is a production process and method that connects metal or other non-metallic materials (like plastics) through the application of heat, high temperatures, or high pressure.

Basic processing flow

Processing advantages

- Powder metallurgy is the primary method used to manufacture refractory metals, their compounds, fake alloys, and porous materials.

- It is possible to lower the expenses associated with metal and product costs.

- Contamination of the materials is completely ruled out, ensuring the extraction of exceptionally pure material.

- Powder metallurgy guarantees the accuracy and consistency of the material composition ratio.

- Powder metallurgy is ideal for manufacturing various products that share a uniform shape, leading to significant cost savings in production.

Processing disadvantages

- When there is no need for batch production, it is important to take into account the size of the part.

- The cost of a mold is comparatively greater than that of a casting mold.

Range of production applicability Powder metallurgy enables the direct production of porous, semi-dense, or fully dense materials and products, including oil bearings, gears, cams, guide rods, and cutting tools.

FORMING OF SEMI-SOLID METALS

Forming of semi-solid metals

SSM, short for Semi-Solid Metal, possesses distinctive rheological characteristics and exceptional stirring fusibility. These properties of SSM can be effectively harnessed to regulate the quality of casting processes.

Semi-solid forming includes two main processes: Rheoforming and Thixoforming.

1 Rheoforming

Technical features

- The reduction in defects resulting from liquid formation has significantly enhanced the quality and reliability.

- The mold experiences significantly less heat impact with a forming temperature lower than that of full-liquid forming.

- This technique has the capability to produce alloys that are not achievable through conventional liquid forming methods.

The application has proven to be effective in various components such as primary cylinders, steering system parts, rocker arms, engine pistons, wheel hubs, drive system parts, fuel system parts, and air conditioner parts across the aviation, electronics, and consumer goods industries.