Galling frequently occurs with metal components, where two moving metal surfaces adhere unexpectedly, resulting in frictional harm and undesired cold welding.

Galling is commonly observed in moving components such as threads, fasteners, bearings, cylinders, and pistons. However, it can also occur in metalworking processes, where tiny fragments of the workpiece stick to the cutting tool of a machine, for instance.

Luckily, there exist numerous methods to avoid galling, whether it be in the production of metal components or during their use. Opting for the right material, applying surface treatments, and ensuring proper lubrication are among the most effective approaches to minimize galling. Nevertheless, certain components and materials are naturally prone to this issue, which can restrict their longevity.

This article examines various approaches to prevent galling on metal parts that slide, with a specific emphasis on the manufacturing aspect. It delves into the topics of materials, manufacturing techniques, and surface treatments.

Table of Contents

Why does galling happen?

Galling is the result of sliding surfaces sticking together due to friction and adhesion. This causes the crystal structure of one surface to be torn and transferred to the other surface, creating a visible raised lump known as a “gall.”

This occurrence happens due to the presence of imperfections, such as tiny peaks and troughs, on even seemingly smooth surfaces at a microscopic level. The contact between these microscopic peaks or asperities of different materials results in friction.

Various elements can worsen the intensity of galling. These factors consist of:

- Insufficient lubrication present between the two sliding surfaces

- A blend of substantial burdens and sluggish gliding velocities

- Utilization of pliable materials

- Utilization of materials featuring a passive oxide layer such as stainless steel and titanium.

- The utilization of identical material on every surface.

- Variations in temperature.

Galling is a common issue that can arise with small components such as threaded fasteners. If not addressed, it can present a significant hazard in industrial operations. When threads become seized, there is a potential for the fastener or even the entire assembly to break.

Galling can result in equipment failure, necessitating costly maintenance, which in turn causes production delays and wastage of resources.

Ways to prevent galling

There are multiple approaches to mitigate or reduce galling of metal parts that slide against each other. In this discussion, our primary emphasis is on the methods employed by manufacturers such as XinYang to prevent galling through material selection and production techniques, rather than the approaches adopted by end-users to prevent it through lubrication and maintenance. It is worth noting that both aspects hold significance in preventing galling.

1. Material selection

Certain materials have a higher tendency to experience galling compared to others. Typically, harder materials exhibit greater resistance to galling in comparison to softer ones, although additional factors must also be taken into account.

Certain materials, namely aluminum, titanium, and austenitic stainless steel, are prone to galling. Nevertheless, these materials are frequently necessary due to their advantageous characteristics, including strength, corrosion resistance, and machinability. In cases where these materials are not indispensable, alternatives such as brass, bronze, and cobalt are far superior in preventing galling.

Galling is less prone to happen when the two sliding surfaces consist of distinct materials, owing to their dissimilar atomic structures.

2. Material hardening treatments

As previously mentioned, materials that exhibit higher rates of work-hardening are less susceptible to galling. In addition to selecting the appropriate material, the hardness of a material can be enhanced through specific metal surface treatments.

Methods such as heat treatment, carburizing, and nitriding can effectively minimize galling-induced damage, especially for stainless steels [1].

3. Surface roughness treatments

Rough textures have the potential to worsen galling, as the unevenness of each surface can cause them to lock together. Conversely, extremely smooth surfaces can also lead to galling, as the absence of any texture prevents the lubricant from being effectively trapped and maintained on the surface.

The optimal surface roughness for avoiding galling is greater than 0.25 mm Ra but less than 1.5 mm Ra.

Surface finishing processes like grinding, polishing, and buffing are effective in decreasing the roughness of materials that have a surface roughness exceeding 1.5 mm Ra. Conversely, treatments such as coarse abrasive blasting can be utilized to enhance surface roughness, as well as conceal any surface imperfections.

4. Anti-galling coatings

Components prone to galling can be protected with anti-galling coatings designed to minimize friction. An example of such a coating is tungsten disulfide, which functions as a dry film lubricant. In contrast to liquid lubricants that need to be reapplied regularly, tungsten disulfide does not draw in dirt and particles.

An alternative method to decrease galling is through the use of electroless nickel or chromium plating, which can enhance corrosion resistance as well. Plating could prove to be highly efficient when selectively applied to one of the two sliding surfaces.

Diamond-like carbon (DLC) is another widely used anti-galling coating that has the ability to greatly enhance the hardness of a metal component’s surface.

5. Part design

To minimize galling and decrease surface pressure, it is advisable to enhance the contact area between sliding surfaces. When creating components, it is recommended to maximize the surface area of contact if feasible. Additionally, the design should facilitate sufficient lubrication of the sliding parts, and the presence of cavities or holes can aid in retaining the lubricant within the contact zone.

It is crucial to define tolerances in the design process. Sliding components must possess adequate clearance to reduce friction and ensure proper functionality.

6. Lubrication

Proper lubrication plays a crucial role in preventing the galling of sliding metal components. By reducing friction and contact temperature, lubrication serves as a protective barrier between surfaces.

Specialty anti-galling lubricants, grease, oil, and anti-seize solutions are commonly used as lubricants to prevent galling.

Ordering metal parts from XinYang

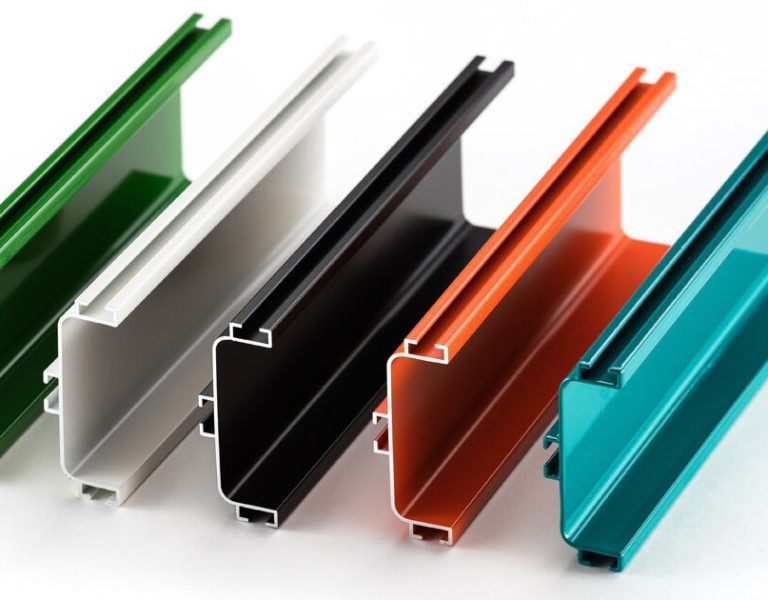

XinYang is a reliable supplier of metal components and prototypes produced through methods such as CNC machining, sheet metal fabrication, metal additive manufacturing, aluminum extrusion, and metal casting.

We provide a vast selection of material choices and also offer surface finishing treatments such as bead blasting and chrome plating. These options assist in the development of sliding components that effectively withstand galling and other obstacles.