Rapid Prototyping: Everything You Need to Know

.

The manufacturing world has been revolutionized by the emergence of rapid prototyping, an umbrella term for a range of manufacturing techniques that can fabricate prototypes and parts in a quick and cost-effective manner. This space has grown immensely over the past few decades, and as methods like additive manufacturing, CNC machining, injection molding and vacuum casting become more affordable and accessible, rapid prototyping has become an integral part of product development across all industries.

In the following guide, we’ll cover every aspect of different rapid prototyping techniques and applications, showcasing the different processes, advantages and common applications. Whether you’re looking for the right rapid prototyping method for your own production plans, or simply want to learn more about the various technologies available to you, our Rapid Prototyping Guide has everything to help you make an informed decision on which prototyping path you venture down.

Table Of Content

Part One

- What is Rapid Prototyping?

- Why Should You Use Rapid Prototyping?

- Types of Prototypes

Part Two

Rapid Prototyping Techniques

- 3D Printing

- CNC Machinig

- Injection Molding

- Vacuum Casting

Part Three

- How to Get a Prototype Made?

- Find a Rapid Prototyping Service

- Request a Quote for Rapid Prototyping

Part 1

.

.

What is Rapid Prototyping?

Rapid prototyping is revolutionizing the approach to product design and production in almost every sector. The most precise explanation of rapid prototyping is as follows:

Rapid prototyping encompasses a variety of manufacturing methods employed to efficiently create a scaled model of a physical component or assembly by utilizing a 3D model.

Additive manufacturing, commonly referred to as 3D printing, is the prevailing method of rapid prototyping. Numerous 3D printing technologies exist, each compatible with various materials and providing unique advantages. In addition to 3D printing, other technologies such as CNC machining, injection molding, and vacuum casting are also capable of rapid prototyping.

Why Should You Use Rapid Prototyping?

1.The primary benefit of rapid prototyping is its ability to transform design concepts into tangible reality. When creating a product or component for large-scale production, the capability to produce physical prototypes plays a vital role in the overall process. Rapid prototyping offers a cost-effective and efficient means to refine designs for mechanical testing and to ensure that the dimensions align with the designer’s vision.

2.Decreasing Production Expenses and Time – Rapid prototyping has the potential to significantly lower total production expenses. For instance, additive manufacturing technology removes the necessity for expensive moulds, patterns, and special tools. Moreover, employing rapid prototyping methods enables you to enhance and rectify any possible flaws in your design prior to its mass production.

Rapid prototyping in the manufacturing industry not only saves time but also accelerates the product development process. This allows for swift design iterations and ensures efficient preparation for mass production.

3.Implement Changes Swiftly – Rapid prototyping not only brings design concepts to life but also allows for quick modifications to be made by designers and engineers. For instance, if a prototype reveals areas for improvement in terms of cost reduction or enhancing user experience, adjustments can be swiftly implemented using technologies like 3D printing or CNC machining. This proactive approach prevents costly setbacks during mass production, as changes can be made efficiently without significant investments of time or money.

4. Personalization – Rapid prototyping enables the development of highly customizable parts and products that can be tailored to meet specific individual requirements. These manufacturing techniques eliminate the need for tooling or complex processes, making it convenient and cost-effective to personalize and iterate your model.

When using traditional manufacturing techniques, even minor changes in a design will alter the entire production process. But with rapid prototyping methods like 3D printing or CNC machining, these changes can be implemented without impacting the overall manufacturing process. This is a major benefit for both companies and consumers, as parts can be given a highly personalized touch.

5.Minimize Design Defects – Utilizing rapid prototyping techniques such as additive manufacturing enables the creation of physical parts or products to verify the absence of any design flaws. Through the use of materials like plastic or metal that closely mimic those intended for the final product, companies can perform physical assessments to confirm if the properties and strength of the components align with their specifications. This early detection of flaws or operational issues during the product development phase helps in saving significant resources in terms of both time and finances.

Types of Prototypes

There are several terms utilized to describe different types of prototypes. When it comes to rapid prototyping, you will discover a wide range of styles available, each designed to fulfill distinct production requirements. Below is a concise summary of the terms that encompass the realm of rapid prototyping.

1. A “looks-like prototype” is primarily concerned with the aesthetics of a product. Its main purpose is to replicate the outer appearance and usability, prioritizing the visual aspect over functionality. By creating a perception or giving a first impression to customers, a looks-like prototype can influence their purchasing decision and determine how the final product will be received in the market. While this type of prototype can be made from various materials, FDM 3D printing technology has gained popularity for its cost-effective ability to produce intricate geometries.

2.Functional Prototype – A functional prototype, also referred to as a “works-like prototype,” is designed to demonstrate the core functionality and mechanical capabilities of your part or product. In addition to the physical object, it is typical to incorporate development boards and other electronic components to illustrate how the prototype will operate in its completed state.

This particular kind of prototype is not required to showcase the visual aesthetics of your product, and may sometimes appear messy or makeshift. However, this is perfectly acceptable. The primary objective here is to assess the functionality of your design. Therefore, when creating a prototype that functions similarly to the final product, the choice of material is crucial, just like the manufacturing process. It is important to select a material that closely resembles the mechanical properties of the one that will be utilized in large-scale production. Consequently, methods such as injection molding, CNC machining, vacuum casting, or industrial-grade 3D printing are commonly employed in these scenarios.

3. Combination Prototype – A combination prototype integrates both the visual and mechanical elements into a single product. This form of prototyping proves beneficial in enhancing the appearance and structure of your product, as well as evaluating the functionality and positioning of electronic components. By employing rapid prototyping methods such as CNC machining or 3D printing, it becomes possible to develop a combination prototype that accurately reproduces both the aesthetic appeal and mechanical attributes of your product.

4. The pre-production prototype is the last stage in the prototyping process, and it closely resembles the final product. This type of prototype is typically created using a manufacturing process that is either the same or similar to the one that will be used for mass production. CNC machining and injection molding are commonly employed as rapid prototyping techniques during this phase. The main objective of pre-production prototypes is to identify and address any potential issues before moving into the final production stage. By utilizing this type of prototype, you can thoroughly examine all specifications and apply for the necessary certifications. As this is the final step before mass production, engineers and manufacturers often take advantage of this opportunity to optimize the design for manufacturing. To ensure a smooth production workflow, it is crucial to consider various factors such as manufacturing, pricing, usability, transportation, user experience, sustainability, and more.

Part 2

In the following sections, we’ll show you the most popular rapid prototyping technique, how to get a prototype made, how to find a rapid prototyping service and how to request a quote from the service provider.

.

Additive Manufacturing (3D Printing Technology)

Additive manufacturing, also known as 3D printing, is widely acknowledged as one of the most favored rapid prototyping methods. Over the last ten years, this technology has made significant progress, with advancements in various aspects. Notably, it has become more cost-effective and easily attainable, making it more accessible to a broader range of users.

Various 3D printing techniques are employed for rapid prototyping purposes, each with its own unique characteristics. It is crucial to familiarize oneself with the commonly utilized methods in order to fully grasp their benefits and applications.

1. Fused Deposition Modeling (FDM) is widely recognized as the most commonly used method in 3D printing. It operates by extruding melted thermoplastic strands through a heated nozzle, gradually constructing an object layer by layer. This technique is extensively utilized in both industrial and consumer sectors. While inexpensive desktop FDM 3D printers are suitable for creating visually appealing prototypes, industrial-grade machines provide enhanced mechanical properties, larger printing capacities, and superior print resolution.

If you require the rapid production of functional plastic prototypes, FDM 3D printing presents itself as an exceptionally cost-effective and feasible choice. This specific method of rapid prototyping is compatible with a wide range of thermoplastic materials commonly utilized in conventional manufacturing, including ABS, Nylon, PLA, TPU/TPE, PET, PC, PEEK, and various others.

Fused Deposition Modeling (FDM) 3D printing stands out as a highly economical method for manufacturing personalized components or models using thermoplastic materials. Opting for a rapid prototyping service ensures a remarkably quick turnaround time of only a few days. Moreover, due to the incremental layer-by-layer construction of the CAD model, wastage of materials is almost non-existent.

The advantages of FDM 3D printing are easily noticeable, however, there are also certain constraints that may not be commonly known. Firstly, FDM lacks high dimensional precision and offers subpar surface resolution when compared to alternative 3D printing methods. Therefore, if you possess a component with intricate or complex features, it would be advisable to explore alternative options. Additionally, the layering procedure presents a few challenges. This is due to the fact that FDM parts exhibit visible layering lines, which necessitate post-processing. Moreover, the layer-by-layer approach inherently results in parts that are anisotropic, meaning their strength is significantly reduced in specific directions.

FDM 3D printing is an effective method for rapid prototyping, especially when speed and cost are important factors. However, for complex parts or functional prototypes with intricate details, it may be beneficial to explore other manufacturing processes.

2. Stereolithography (SLA) is a rapidly growing 3D printing technology that is gaining popularity. This technique involves using a powerful laser to solidify a 3D model, layer by layer, using a vat of resin. SLA 3D printers are renowned for their ability to produce high-resolution prints quickly, making them a preferred choice for creating visual models, prototypes, as well as medical and dental models.

Various resin materials tailored for specific applications are available in the market, each designed to fulfill distinct part specifications.

SLA 3D printing provides numerous advantages, particularly when there is a requirement for an extremely lifelike prototype or model. It ensures remarkable accuracy and exceptional resolution by creating remarkably thin layers using a fine laser beam. Additionally, it simplifies the production of intricate and complex prototypes, surpassing the capabilities of many other rapid prototyping techniques.

The primary advantage of utilizing SLA 3D printing lies in its exceptional surface quality. Objects created through this method generally exhibit a polished appearance and impressive layer precision. SLA enables designers to fabricate both minuscule components and larger parts with utmost accuracy akin to professional standards.

In addition to low lead times and cost, there are various other advantages associated with utilizing SLA 3D printing via a rapid prototyping service.

However, there are drawbacks associated with SLA in the context of rapid prototyping applications, particularly those that necessitate mechanical testing or large-volume production. While prototypes created using this technique boast exceptional surface quality, they often lack durability, making them unsuitable for mechanical testing. Additionally, compared to alternative rapid prototyping methods, SLA 3D printing is relatively slow due to post-processing requirements and limitations on build volume. Consequently, the practicality of producing a large quantity of prototypes using SLA is questionable.

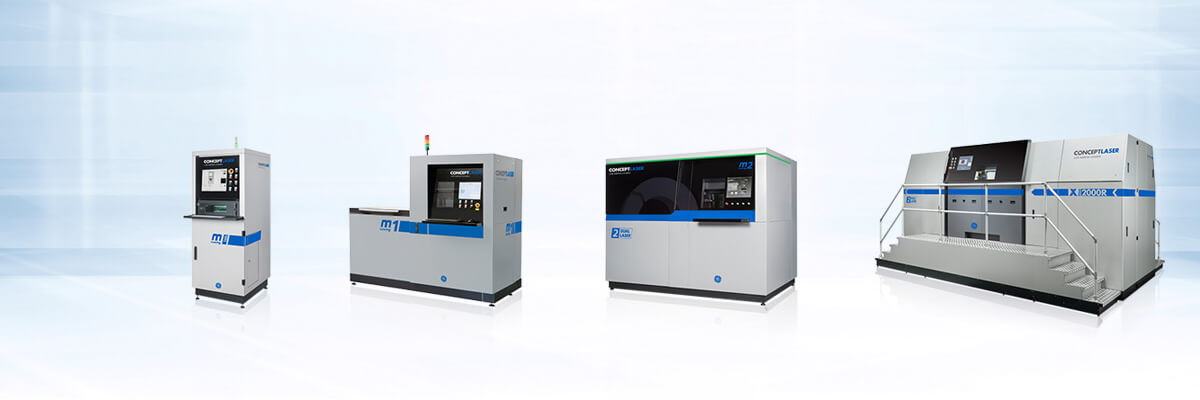

4. Selective Laser Sintering (SLS)/Direct Metal Laser Sintering (DMLS) – SLS is an advanced method for creating prototypes by using a powerful laser to fuse powdered material together. This technique involves scanning cross-sections from a computer-aided design (CAD) model and selectively sintering the powdered material to form each layer of the prototype. The process is carried out on a bed filled with powder, where a new layer is added once the previous layer has been solidified.

SLS 3D printing is commonly employed for creating plastic prototypes, whereas the process known as direct metal laser sintering (DMLS) is utilized for metal production. DMLS, which falls under the umbrella of SLS, employs a high power-density laser to melt and fuse metallic powders together, as opposed to plastics.

SLS, despite its advantages, does have certain drawbacks. The primary concern is the occasional porosity and roughness of the surface. Additionally, plastic components produced through SLS may encounter challenges related to thermal distortion, resulting in shrinkage and warping. Nevertheless, these issues can be effectively addressed by employing the expertise of a proficient rapid prototyping service.

3D Printing _Rapid Prototyping Techniques

Prior to proceeding, let us provide a concise summary of the benefits associated with the previously mentioned techniques utilized in the realm of 3D printing.

If you are facing strict time and budget constraints, and are willing to compromise on the surface quality and mechanical properties of a physical prototype, FDM 3D printing would likely be the most suitable choice for you.

If you prioritize the visual aspect of your prototype and are willing to handle a more delicate component, SLA 3D printing is the preferred choice over FDM. On the other hand, if you require a plastic or metal prototype with excellent surface quality and reliable mechanical properties, SLS or DMLS would be the ideal option.

While 3D printing is often hailed as the primary method for rapid prototyping, there exist alternative processes that can be leveraged to your benefit. Depending on the specific part design and intended application, CNC machining, injection molding, or vacuum casting may offer more value. Let us delve into the workings of these three manufacturing techniques and explore the benefits they offer in the realm of rapid prototyping.

CNC Prototype Machining _Rapid Prototyping Techniques

As previously stated, rapid prototyping extends beyond 3D printing. In reality, CNC machining can offer even greater benefits depending on the specific application and part requirements. Unlike 3D printing, which is an additive process, CNC prototype machining follows a subtractive manufacturing technique. This means that it utilizes cutting tools to remove material from a solid block of plastic or metal, resulting in the production of a prototype or part.

The procedure involves using digital commands from a CAD or CAM document to precisely cut the required component using a range of cutting and drilling equipment. In instances where intricate prototypes demand diverse cutting techniques, the machining head can automatically switch between multiple tools.

The majority of professional rapid prototyping service providers utilize 3-, 4-, and 5-axis CNC machines. 3-axis machines can move horizontally on the x, y, and z-axis, whereas the more sophisticated 5-axis machine can rotate a part and work on both sides of a material. Occasionally, a combination of additive manufacturing and CNC machining is employed to create prototypes.

CNC machining offers a significant benefit in terms of material flexibility. This advanced prototyping method is highly compatible with a wide array of engineering-grade plastics and metals, such as aluminum, brass, copper, steel, and titanium. Moreover, it also allows for the utilization of materials like wood, foam, and fiberglass, expanding the possibilities even further.

CNC machining also has its drawbacks. Operating these machines can be expensive, and it necessitates a proficient operator to guarantee a seamless process. However, these challenges can be easily overcome by utilizing a rapid prototyping service. Moreover, there are certain limitations in terms of design, as the size of the part is restricted by the material substrate. Additionally, CNC machining falls short in achieving certain intricacies that additive manufacturing techniques can accomplish.

In summary, CNC machining proves to be an excellent method for rapid prototyping, particularly for producing small-to-medium quantities of parts that exhibit both precision and consistency. This technique is particularly advantageous for creating functional components using metal or transparent PMMA, as it ensures exceptional repeatability and offers advanced mechanical properties.

Injection Molding _Rapid Prototyping Techniques

Despite being viewed as a conventional manufacturing method in contrast to 3D printing, injection molding and rapid tooling can also serve specific rapid prototyping purposes. Its suitability for extensive production lies in its remarkable consistency and swift turnaround time. The injection molding procedure commences with the creation of a mold or die, which is divided into two halves. Following the production of the mold, usually through CNC machining using hardened steel or aluminum, it is readied for injection molding.

The enjoyable phase is now upon us… Initially, a granular form of either a thermoset (epoxy resin) or thermoplastic material is introduced into a heating barrel. Once the desired temperature is attained, the molten material is forcefully injected into the mold, subjecting it to immense pressure to solidify the component prior to commencing the cooling process. After the completion of the cooling process, the mold is opened and the component is expelled. This procedure can be replicated countless times, rendering it the preferred choice for high-volume manufacturing.

Injection molding offers the benefit of creating prototypes with intricate features and complex geometries. The application of high pressure in the injection molding process enables the incorporation of detailed elements into the design. Additionally, it allows for the production of intricate and complex shapes that may not be achievable through conventional manufacturing methods.

Designing and manufacturing a functional mold for injection molding may require a significant amount of time, however, the actual molding process itself is remarkably quick and efficient. This allows for the rapid prototyping of a high volume of parts within a short timeframe, making injection molding a cost-effective option.

Injection molding is advantageous for rapid prototyping due to the ability to enhance the strength of parts. By incorporating filler materials into molds, part density can be reduced and strength can be increased post-molding. Injection molded parts exhibit significantly greater strength compared to those produced through 3D printing. Furthermore, the option to utilize a combination of materials in a single part allows for the enhancement of strength, reduction of weight, and attainment of various mechanical properties. Additionally, injection molding boasts minimal material wastage, as all material is utilized or can be recycled throughout the manufacturing process.

If you need a functional prototype for your rapid prototyping application that can be tested or if you require a large-volume production, injection molding could be the most suitable option for you. However, one drawback is the intricate process of designing a foolproof mold, which involves numerous design considerations. Fortunately, you can utilize a rapid prototyping service to assist in designing and optimizing your mold prior to its production.

Vacuum Casting _Rapid Prototyping Techniques

Vacuum casting is a rapid prototyping technique that is both fast and cost-effective. Similar to injection molding, it utilizes a mold in the process. The initial step involves placing a two-piece silicone mold into a vacuum chamber. Subsequently, a raw material is mixed and poured into the mold, allowing the part to solidify within the vacuum chamber. Following this, the casting is cured in an oven, and upon releasing the mold, a finished part is revealed.

Vacuum casting molds are capable of being reused for a limited number of times, typically around 20 or more, which makes them highly suitable for low-volume prototyping needs. The parts manufactured through vacuum casting exhibit a remarkable combination of flexibility and rigidity, and can be produced in a wide range of colors and resin materials, including ABS, POM, Elastomers, Nylon, and others.

Vacuum casting is utilized to produce components with outstanding mechanical characteristics, making it well-suited for functional prototyping. Moreover, it has the ability to manufacture components with precise accuracy and intricate visual details, including patterns, dimensions, profiles, and textures. As a result, vacuum casting is highly beneficial for the creation of vibrant products and promotional materials.

Although vacuum casting offers flexibility and efficiency, it also comes with drawbacks. One disadvantage is the higher cost of vacuum forming molds compared to injection molding, especially for high-volume manufacturing. Additionally, expenses for post-processing and finishing can be significant, leading to longer production times. Furthermore, vacuum casting may struggle to replicate certain intricate details as accurately as 3D printing or CNC machining.

Part 3

.

How to Get a Prototype Made?

There are several options available depending on the type of prototype you require. If you are looking to create a prototype that is primarily for aesthetic purposes and doesn’t require extensive functionality, you have the choice to invest in your own 3D printer or CNC milling kit. The market for desktop 3D printers offers a wide range of options to choose from.

There is likely a 3D printer available that will meet your rapid prototyping requirements, whether you prioritize affordability, reliability, or part quality. Additionally, CNC milling kits have become more accessible and affordable for designers, engineers, and small businesses.

If you require the creation of a functional prototype or a prototype with outstanding visual quality, it is advisable to utilize the services of a rapid prototyping service to handle the necessary tasks. By engaging a rapid prototyping service, you gain access to a wide range of manufacturing techniques and materials. With esteemed manufacturing services such as XinYang, you also benefit from expert guidance on optimizing your design and selecting the most suitable rapid prototyping technique for your specific requirements.

In summary, if you wish to invest in your own rapid prototyping technology, you can efficiently iterate and enhance aesthetic prototypes without the need for complex mechanical properties. Nevertheless, when it comes to developing a functional prototype that will endure stress, high temperatures, conductivity, or other environmental factors commonly encountered in real-world applications, it is advisable to seek assistance from the 3ERP rapid prototyping service.

Find a Rapid Prototyping Service

Once you have made the decision to enlist the assistance of a professional rapid prototyping service in order to materialize your product, the subsequent task entails locating the most suitable service provider. Several alternatives are available for you to consider.

The most convenient method to locate a rapid prototyping service is by conducting a basic search on Google or Bing. Whether you prefer a local service or a global provider such as 3ERP, the internet will guide you in the correct direction. By performing an online search, you can access testimonials and reviews, gather information about the manufacturing techniques and prices offered by each service, and effortlessly connect with industry experts.

Online directories can be a valuable resource for locating a rapid prototyping service, depending on the geographical location of your business. The decision to opt for a local or international service provider will largely depend on factors such as product size and turnaround time. Utilizing an online directory can prove highly advantageous in this regard. By accessing a comprehensive list of rapid prototyping services, you gain the ability to compare and contrast various manufacturers, each with their own unique advantages and disadvantages. This consolidated approach facilitates a swift and efficient search for the most suitable provider to meet your prototyping requirements.

Attending manufacturing trade shows is an excellent method to establish stronger connections and personally engage with representatives from rapid prototyping services. These events provide a platform similar to an online directory, where companies from around the world gather, allowing you to have face-to-face conversations and explore the offerings of each participant.

Utilize your professional or social connections to inquire about the individuals or companies they have utilized for prototype creation. Request their recommendations or guidance in finding the appropriate resources. Acquiring a personal endorsement from a familiar source will offer reassurance, mitigating any potential risks or challenges that may arise from thoroughly evaluating a rapid prototyping service.

How to Request a Quote for Rapid Prototyping

After completing your design and conducting an extensive search for the ideal rapid prototyping service, there is one final step remaining: submitting a request for a quote (RFQ). Prior to reaching out to your chosen rapid prototyping service for pricing, it is crucial to review your documentation and 3D models to ensure that all part requirements and acceptance criteria are explicitly stated. By furnishing the manufacturing service with comprehensive information, you minimize the risk of receiving an unsatisfactory prototype.

Fortunately, there exist rapid prototyping services that surpass expectations by actively engaging with customers to understand their requirements and part specifications. At 3ERP, we boast a team of skilled professionals who are ready to guide you through the complex stages of design and manufacturing options. Nevertheless, to ensure a comprehensive understanding of your prototype, it is crucial to include all relevant details and information when submitting your RFQ.

The process of planning necessitates more than mere contemplation of the prototype. It is essential to thoroughly deliberate on various factors such as shipping alternatives, assembly procedures, payment methods, materials, and turnaround time. To ensure utmost security, it is advisable to have a signed NDA and non-compete agreement in place prior to dispatching the 3D models or drawings.

After addressing all those aspects, you will be ready to send a Request for Quotation to the rapid prototyping service.

Version 1: If you are prepared to begin, please reach out to XinYang for further information on our rapid prototyping services and to strategize the initial crucial phase of product development.