.

.

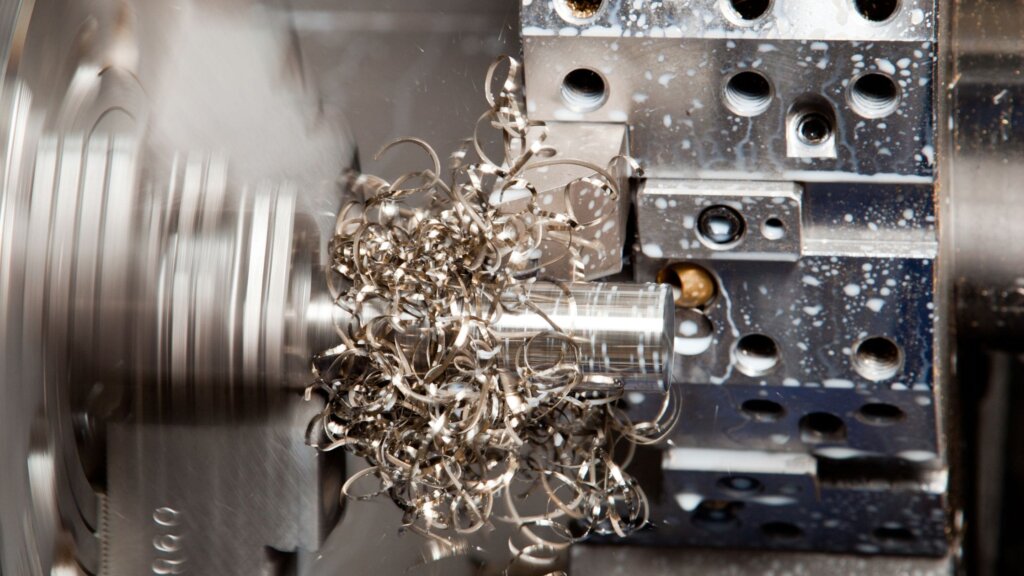

What is Machining: Definition, Types & Tools

The majority of the manufactured goods that surround you are produced through machining procedures. This has been the norm for hundreds of years, with the different stages of the process undergoing significant transformations over time.

Numerous individuals frequently inquire about the fundamentals of machining, its operational mechanisms, the various types of machining processes, and numerous other intricacies related to these subjects. This article aims to delve into all of this information and beyond, offering a comprehensive understanding of the machining industry.

What is Machining?

Machining refers to a manufacturing technique that entails shaping a material into its desired final form by systematically eliminating material. This process employs machine tools such as machining centers to effectively remove material, thus earning the label of subtractive manufacturing. In contrast, additive manufacturing involves the deliberate addition of material in a controlled manner.

Machining techniques are capable of processing a wide variety of materials such as metals, plastics, wood, glass, and others. The versatility of machining methods across this extensive spectrum allows for their utilization in a multitude of industries.

History of Machining Processes

Machining processes have been around for centuries, with roots tracing back to the 18th century. During this time, machining was primarily focused on repairing machines and equipment through labor-intensive methods like wood carving and metalworking through forging. While the term ‘machinists’ was in use, the concept of ‘machining tools’ had not yet emerged.

In the middle of the 20th century, the advent of machining tools took place. This occurrence was a result of the introduction of various machining processes including drilling, turning, boring, milling, broaching, planing, sawing, reaming, taping, and more. Initially, these processes were carried out using manually operated machining tools such as basic lathes, drilling tools, cutting tools, or drill presses. However, as time passed and technology advanced, the integration of computers and other technologies led to the association of all machining processes with Computer Numerical Control (CNC).

How Does Machining Work?

The fundamental principle of machining involves beginning with a larger material piece than the final desired part and subsequently eliminating the excess material using a precisely controlled cutting tool. In today’s advanced manufacturing industry, the operation of machining tools is governed by Computer Numerical Control (CNC) technologies. This method follows a systematic approach, commencing with the conceptual design of the intended shape and subsequently implementing the design on the machining tools.

Stages of the Machining Process

The sequence of steps for machining any component is as follows:

Creating Blueprints

To begin with, it is crucial to establish a conceptual understanding of the necessary component. This is achieved by utilizing engineering drawings and blueprints that outline the desired dimensions of the part. When determining these dimensions, it is vital to consider the feasibility of materials and their mechanical durability. For example, a wall must possess a minimum thickness to prevent potential collapse during the machining process.

Creating CAD Models

After the completion of the blueprints for the component, the next step involves transforming it into a digital 3D model. This task is carried out through the utilization of Computer Aided Design (CAD) software, which is typically handled by a skilled programmer. For intricate parts, sophisticated CAD programs are necessary.

The CAD models are transformed into Computer Aided Manufacturing (CAM) programs, which serve as the communication medium for the CNC machine. CAD software can also detect potential design flaws that may result in errors during the machining process.

Machine Setup

The operator is responsible for performing the machine setup, which entails making adjustments to the tooling and securely placing the workpiece materials onto the CNC machine. The specific setup requirements may differ depending on the type of machining process that will be performed. Additionally, the setup process involves transferring the CAD instructions to the machine.

Program Execution

Upon completion of the machine setup, the operator initiates the program. Subsequently, the machine proceeds to shape the program into the final part. This process can be carried out using various methods, which are determined by the specific machine in operation. Once the program has been executed, the final part is prepared and removed by the operator. Depending on the specifications, the final part may then be forwarded for additional machining procedures.

Applications of Machining

Machining tools are utilized across various industries to produce a diverse range of parts. Several typical equipment types and machining process applications include:

Bicycle frames

Scientific projects

Medical and surgical equipment

Engines

Aerospace parts

many other parts

Smartphone and laptop cases

Military and firearms equipment

What are the Different Types of Machining Processes?

Various machining processes and operations exist, each serving a specific purpose and designed for specific tasks. Below is a concise summary of these diverse machining processes.

Turning

The turning process involves the rotation of the workpiece around a central axis, while the cutting tool removes material from it. This technique is commonly employed for achieving symmetrical shaping of the workpiece. Notably, the cutting tool can be computer-controlled, enhancing precision and efficiency. Various applications of the turning process exist, serving diverse purposes:

Engine components

Threads

Machine components

Tapers

Shafts

Milling

The process of milling utilizes a cutting surface that rotates and moves against the workpiece in order to produce various plane shapes. These cutting shapes can vary from basic straight cuts to angled and inclined surfaces tailored for specific needs. A variety of milling tools, including bed mills, column mills, gantry mills, C-frame mills, knee mills, turret mills, ram-type mills, and others, are available to achieve this. Various applications of milling tools include:

Gears

Agricultural equipment

Slotting and Grooves

Automotive parts

Aerospace components

Energy sector

Drilling

Drilling tools are considered to be among the most basic forms of machining equipment. Their primary function is to maneuver across the workpiece and generate holes using drill presses. These holes serve various purposes such as accommodating screws, facilitating secondary assembly, or simply enhancing the overall appearance. The applications of drilling encompass a wide range of tasks:

Screw holes

Fluid assembly ends

Fuel injector bodies

Aircraft landing gear

Heat exchanger tubes

Boring

Boring tools are utilized to expand pre-existing drilled holes in the workpiece. This can be achieved using either a single-point cutting tool or a collection of such tools. Boring serves as a complementary process to turning, with the main distinction being that boring focuses on the internal diameter while turning tools handle the external diameter. Notable applications of this technique can be observed in the manufacturing of firearm barrels or engine cylinders. The versatility of boring is evident in its various applications:

Engine cylinders in the automotive industry

Firearms

Cranes and end loaders

Mining

Reaming

Reaming is a method utilized to slightly enlarge the diameter of a pre-drilled hole and enhance its internal surface finish. This technique becomes necessary when a hole of specific diameter or surface finish is needed, beyond the capabilities of drilling tools. Typically, the procedure involves first drilling a hole that is slightly smaller in size, followed by the use of reaming to achieve the desired width and finish. The applications of reaming are diverse and include:

Screw cutting

Turret lathe

Removing burrs

Grinding

Grinding is employed to eliminate a minimal quantity of undesired material from a workpiece in order to achieve a polished surface and guarantee utmost accuracy in dimensions. This technique employs an abrasive surface known as a grinding wheel as the tool for cutting. Various types of grinding tools are available, ranging from manual to computerized options. Angle grinders, die grinders, and bench grinders are commonly utilized grinding tools. Grinding finds its applications in various fields:

Brake cylinders and pistons

Surgical drills

Aerospace components

Hydraulic steering pistons

Hip stems

Furniture industry

Gear shafts

Femoral knee joints

Planing

Planing involves the creation of smooth, flat surfaces on a workpiece using a machine known as a planer. The cutting action is achieved by the movement between a single-point cutting tool and the workpiece. In addition to linear planing, planers can also be utilized for helical planing tasks. The applications of planing are diverse and encompass various purposes:

Generate flat surface for any requirements

Creating multiple slots at the same time

Sawing

Sawing is considered one of the oldest methods of machining. It involves the use of a sharp blade, which can sometimes be substituted with a wire or chain that has toothed edges. While sawing is predominantly used in woodworking, it also has various applications in metalworking and stone cutting.

Wood cutting

Tile cutting

House making

Furniture making

Broaching

Broaching involves the removal of unwanted material using a toothed cutting tool known as a ‘broach’. There are two methods of broaching: linear and rotary, with the linear method being the more widely used. This technique is ideal for accurately machining unique shapes. Some typical applications of broaching include:

Internal keyways

Screw machine parts

Non-circular holes

Stampings

Splines

Burning Machining Techniques

The thermal machining process employs elevated temperatures to eliminate material, as opposed to the traditional machining methods that rely on sharp cutting tools. Essentially, the material is melted away by the heat generated from the thermal tools. The melting process varies depending on the specific thermal techniques employed. There are three prevalent methods of thermal machining techniques.

Laser Cutting:

Laser cutting involves the elimination of material by means of a concentrated light beam. This technique is employed to cut materials into any desired shape. It is applicable to both metallic and non-metallic substances. Laser cutting stands as one of the most accurate methods for cutting. Numerous applications can be found for this cutting technique:

Foils

Label Stock and PSA

Plastics

Films

Rubber

Textiles

Laminates

Gaskets

Aggressive Adhesive Materials

Plasma Cutting:

Plasma cutting utilizes an ionized gas stream to melt and eliminate material. This method necessitates the workpiece to be able to conduct electricity, making it suitable only for metals and conductive alloys. Various uses of plasma cutting include:

Fabrication workshops

Industrial construction

Automotive repair and customization

Salvage and scrapping

Oxy Fuel Cutting:

Oxy fuel cutting, commonly referred to as gas cutting, is an age-old technique that involves the use of a combination of oxygen and a flammable fuel gas (such as acetylene, natural gas, propane, or propylene) to melt away material. While not as accurate as laser or plasma cutting, this method offers the advantage of being extremely portable. Various industries utilize this process for different applications:

Stone working

Hardfacing

Automotive industry

Welding

Loosening seized fasteners

Erosion Machining Techniques

Erosion machining methods eliminate material by transforming it into particles that are then eliminated through the machining process. Similar to burning machining methods, there exist various approaches to carry out erosion machining.

Water Jet Cutting

Water jet cutting is a widely utilized technique that harnesses the intense power of high-pressure water to facilitate cutting. It is effective on a wide range of materials including metals, wood, stone, ceramics, plastics, paper, rubber, and others. The resulting shapes can be intricate and complex, varying based on the number of axes present in the machine. Numerous applications exist for this method:

Paper industry

Insulators

Mining

Surgical equipment

Art installations

Food industry

EDM Cutting

EDM, an acronym for Electric Discharge Machining, is also known by various other names including spark erosion, spark machining, wire burning, wire erosion, or die sinking. It finds its application in the metal fabrication industry, specifically for electrically conductive materials. The process involves the removal of material through the rapid sparks or discharges caused by an electrical arc, which is generated by a high voltage. This method has various applications in different industries.

Prototyping

Closed loop manufacturing

Dies for coin production

Metal disintegration machining

CNC Machining

CNC machining is a technology utilized in various machining methods, rather than being a method on its own. It involves Computer Numerical Control, enabling machines to be controlled automatically. Although it necessitates a significant upfront investment and a proficient operator, it ultimately reduces labor expenses and time. Given the demand for high production rates in contemporary industries, CNC machining is widely employed.

Precision Machining

Precision machining involves advanced CNC machining techniques to produce parts with exceptional accuracy. This method incorporates a range of machining processes, ensuring top-notch quality in cutting tools, tooling, and related components. It is essential in sectors demanding consistent precision on a micro or nano level, including electronics, aerospace, military, medical, and similar industries.

What Materials Can Be Machined?

The possibilities are endless when it comes to the materials that can be subjected to machining processes. Some of the commonly chosen options include:

Aluminum

Aluminum’s combination of low weight and high strength renders it a desirable material for numerous manufacturers, hence its prevalence as one of the most widely used materials for machining. Machining processes are applicable to various grades of aluminum, including Aluminum 6061, 7075, 6082, 5083, and others.

Steel

Steel, a composite of iron and carbon, is an incredibly adaptable and durable substance. By adjusting the carbon content, numerous distinct types of steel can be produced. Each of these steel variations possesses the ability to be machined. A few prevalent examples include stainless steel, carbon steel, and mild steel, among others.

Brass

Brass, despite its high cost, is frequently used in machining processes. Brass machining is commonly seen in the creation of art pieces and sculptures.

Titanium

Titanium is renowned for being one of the most resilient metals available. The process of machining titanium components is employed specifically when the desired specifications necessitate the exceptional strength and density properties that titanium possesses.

Wood

Woodworking machine shops have been widespread for an extended period. Wood processing is frequently carried out for the production of furniture, intricate carvings, and various other uses.

Plastics

Plastics encompass a broad category on their own. Machining is applicable to all types of plastics, including thermoplastics and thermosetting plastics. The process of machining plastics offers superior precision compared to alternative methods like injection molding or 3D printing.

Frequently Asked Questions

Below are the responses to frequently asked questions about machining:

Is machining difficult?

The level of difficulty in machining is contingent upon the intricacy of the fabricated component and the proficiency of the team. A team possessing exceptional skills can effortlessly machine a complex part, whereas an unskilled team may encounter challenges in machining even the simplest of parts.

What is the most common machining process?

Drilling and grinding are widely employed machining techniques, extensively utilized across various industries and in conjunction with numerous other machining methods.

What is the difference between machining and manufacturing?

Manufacturing encompasses a wide range of activities, including both additive and subtractive processes. Nevertheless, machining solely focuses on subtractive manufacturing methods.

Start Your CNC Project Today

XinYang specializes in precision CNC machining and CNC prototyping services. Our extensive capabilities encompass milling, turning, wire EDM, aluminum machining, and more. By leveraging our skilled machining experts and advanced 3-, 4-, and 5-axis CNC machining capabilities, we consistently deliver exceptional precision, quality, and complexity for even the most intricate and crucial applications. With our years of experience in the industry, we possess the expertise to offer comprehensive precision machining services that adhere to the standards of various industries.

To gain further insights into the advantages that our rapid prototyping and CNC machining services can offer to your upcoming project, kindly get in touch with us or submit a quote request today.