Table of Contents

The Complete XinYang Production Guide

Selecting the Appropriate Procedure for Your Bespoke Components.

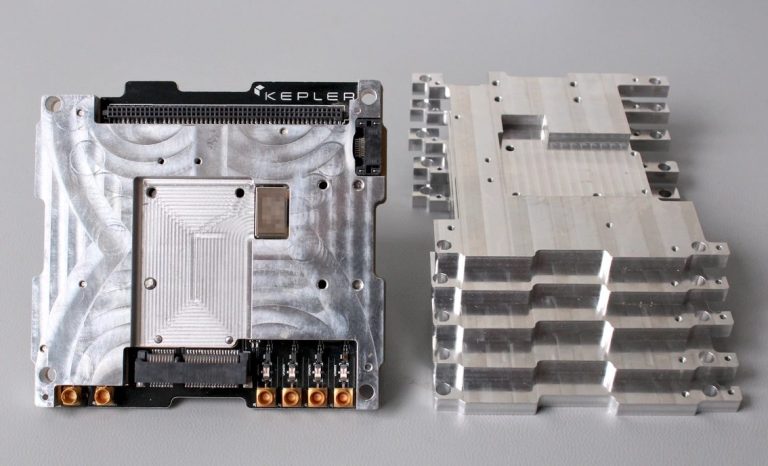

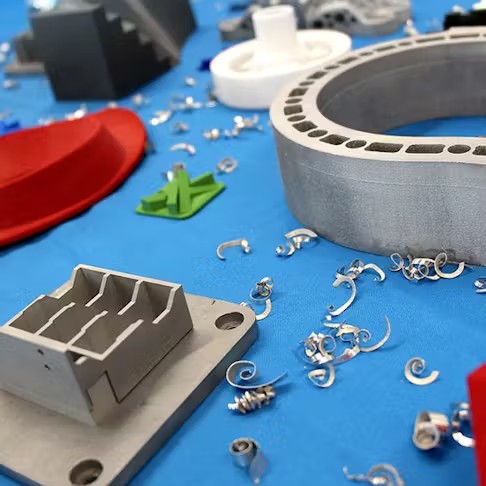

CNC Machining

XinYang’s Internet-based CNC Machining Solutions.

XinYang stands at the forefront of the industry, providing exceptional custom CNC machining services for both rapid prototyping and production parts. Our team meticulously inspects the parts and efficiently manages your order to ensure utmost satisfaction.

We possess an extensive network of partners, ensuring that regardless of your requirement, we have both a suitable shop and a capable machine to fulfill it. Our integration is flawless with more than 3,000 carefully selected manufacturing partners in the United States, Moreover, we hold certifications for ISO 9001further validating our commitment to quality.

XinYang eliminates the uncertainty in CNC part sourcing by offering a wide selection of qualified shops and more than 40 certified materials. Our partners excel in CNC machining and turning processes, handling intricate part designs and delivering superior surface finishes. We guarantee precision and timeliness by machining and inspecting to any 2D drawing, ensuring you receive high-quality CNC machined parts promptly.

Discover more about CNC Machining through XinYang.

Advantages of CNC Machining

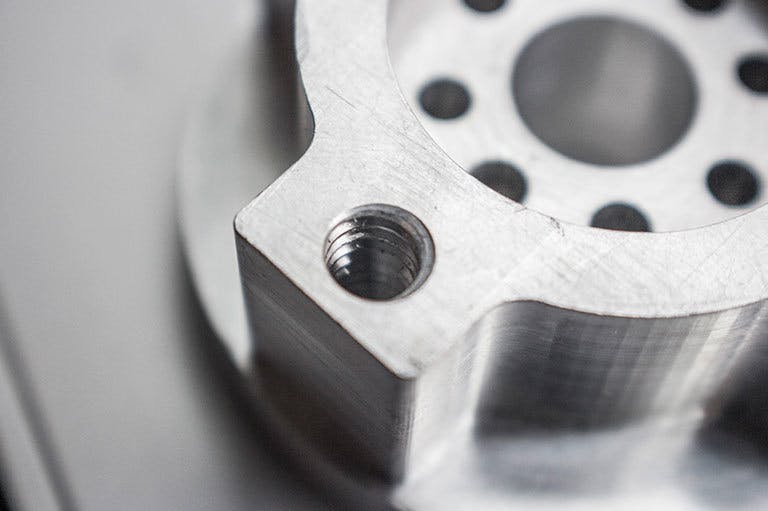

Unparalleled Accuracy and Superior Craftsmanship

CNC Machining stands as a rapid and precise technique, offering the ability to fabricate top-notch components suitable for a wide range of purposes. By employing high-speed and accurate machines, CNC effectively eliminates material, utilizing an extensive array of cutting tools to bring the desired design to life.

Economical With Minimal Setup

We provide 5-axis CNC Machining services to efficiently manufacture precise components with minimal setup requirements in a timely manner.

The Compromises Involved in CNC Machining

Due to the expenses associated with material and setup, CNC Machining may prove to be pricier when dealing with smaller part quantities. Some features, particularly those inaccessible to the milling tool, may not be achievable. Sharp interior corners are required to have a minimum radius of 0.0156”, while square interior corners will have a corner radius equal to 1/8 of the pocket depth.

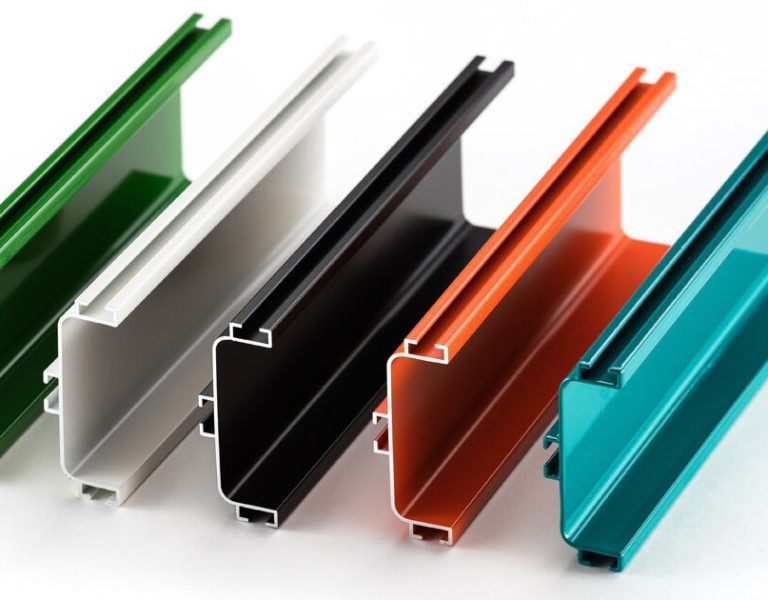

Sheet Metal Fabrication

Xometry’s Sheet Metal Fabrication Services

Sheet metal fabrication involves the transformation of metal sheets into various parts. By converting 3D CAD files into machine code, a machine is able to accurately cut and shape the sheets to create the desired final product. This process utilizes tools such as brakes, punches, and dies to create angular bends and other features on the metal sheets.

Sheet metal fabrication involves the transformation of metal sheets into various parts. a machine is able to accurately cut and shape the sheets to create the desired final product. This process utilizes tools such as brakes, punches, and dies to create angular bends and other features on the metal sheets.

Our tailored sheet metal solutions provide an affordable and readily available option for all your manufacturing requirements. From small-scale prototypes to large-scale production, our fabrication services deliver substantial savings.

Discover additional information about sheet metal fabrication through XinYang

The Advantages of Sheet Metal

Manufacturing Standards

Our sheet metal fabrication services encompass bending, punching, and cutting various metals to create parts suitable for low to high volume production. These parts are recognized for their exceptional durability and precision, making them ideal for end-use applications.

Long-lasting and Consistent Thickness

Sheet metal fabrication is utilized to manufacture thin-walled metal components that are not feasible to produce using CNC Machining. Chassis, enclosures, and brackets are ideal candidates for Sheet Metal Fabrication due to their requirement for uniform thickness, rigidity, and durability.

Bulk Discounts

As the quantity increases, the price per part experiences a significant decrease owing to the ability to pattern multiple parts on the same stock of material.

The Balancing Act of Using Sheet Metal

Sheet metal can be quite costly when producing smaller quantities of parts because of the expenses associated with tooling, setup, and materials. Additionally, sheet metal fabrication is not suitable for parts that have uneven or thick walls. Moreover, sharp interior corners are not compatible with this manufacturing method since the bending process involves machinery with rounded corners.

Stereolithography, also known as SLA, is a 3D printing technology

XinYang’s 3D Printing Services with SLA Technology.

Stereolithography (SLA) is an advanced 3D printing technique renowned for its ability to create precise and detailed components suitable for direct utilization in end-use applications, low-volume manufacturing, or rapid prototyping.

Stereolithography, a form of additive manufacturing, utilizes ultraviolet (UV) light to concentrate on a reservoir of photopolymer resin. This technique surpasses various other 3D printing technologies in terms of resolution, enabling users to produce intricately detailed and finely finished parts. Stereolithography 3D printing serves as a versatile platform for creating customized components in both prototype and production environments, often substituting injection-molded plastic parts.

XinYang provides customers with the choice between standard and high-resolution options for intricate parts, as well as the capability to print larger-sized parts and products, with a maximum build area of 29 inches. Moreover, our partnership We proudly offer a diverse range of materials from renowned brands such as Accura and Somos.

Gain further insights into SLA 3D printing through xometry’s resources

The Advantages of SLA 3D Printing

Effortless Transitions

SLA components exhibit an exceptionally smooth surface, resembling glass, which surpasses the smoothness achieved by other 3D printing methods. This remarkable finish is achieved through their UV curing process. (Please note that a matte finish option is also provided.)

Tangible Images

SLA parts provide product developers with a cost-effective and efficient way to bring their designs to life quickly through high-resolution prints and versatility during the iterative process.

Thorough and meticulous

SLA’s accuracy and faithfulness enable the creation of intricate details, like embossing, which may not be achievable using alternative 3D printing methods.

The Compromises Involved in SLA 3D Printing

Long and wide objects are prone to uneven curing, resulting in potential warping. Additionally, they are more vulnerable to distortion caused by heat and moisture, which may occur during post-processing or shipping. Similar to other 3D Printing methods, there is a possibility of insufficient resolution for extremely small details. To prevent resolution errors, it is crucial to adhere to the minimum suggested dimensions.